Agricultural Industry Manufacturers, Suppliers & Companies

-

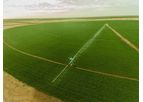

AFKO Pivot Irrigation Systems is a global leader in advanced irrigation solutions. Based in Ankara, Turkey, AFKO specializes in providing state-of-the-art irrigation systems designed to enhance agricultural productivity while conserving water ...

AFKO - Small Center Pivot Irrigation System

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus ...

CONTACT SUPPLIER -

Since 1987, for over 30 years, TECNIDRO designs, develops, manufactures and markets automatic hydraulic valves and water control systems all over the world. The company founded in 1987 from Eng. Alberto Lodolo is well known all over the world for ...

-

UP Umweltanalytische Produkte GmbH is specialized in the development, production, marketing and sales of environmental analytical products in the areas of soilphysics, hydrology, plantphysiology and meteorology. We offer single measurement devices ...

Cherry-Zipper - Model 25700 - Fruit and Stem Holding Testing Mobile Device

Cherryzipper - a mobile device to measure the holding force between fruit and stem. The device is to be hold with one hand, measurements are transmitted to the rugged PDA via Bluetooth. Delivery includes spare battery, charger, carrying case. ...

CONTACT SUPPLIER -

Aanderaa Data Instruments develops, manufactures and markets oceanographic and meteorological instruments and special systems for collecting environmental data. Data can be stored internally in a highly protected memory or transferred in real-time ...

-

For.Tec. it is an Italian company with fifty years of experience in the design, construction, sale and installation of high-tech ecological systems. Thanks to in-depth engineering studies and the collaboration of technical experts, we are able to ...

For.Tec. - Model EXCE AN - Incinerator

EXCE AN incinerators are discontinuous static ovens, top ...

CONTACT SUPPLIER -

With over a century of global experience Landustrie has become a leading player in the field of water and wastewater management. Our basis was laid around 1913. The company was active in the agricultural market sector and involved with polder ...

-

We design and manufacture world-class gas analysis systems and emission monitoring solutions to measure gaseous emissions from industrial processes, gases released from natural sources into the atmosphere, and gases present in working environments. ...

-

Proco Products, Inc. is a global leader in the design and manufacturing of piping/ducting system expansion joints. We offer the most complete line of rubber and molded PFA expansion joints, fabric fan connectors, braided flexible hose assemblies and ...

-

In the last decades IMKO established as leading manufacturer for TDR moisture measurement instruments. Get to know our experts for precise moisture measurement. We develop, produce and distribute state-of-the art measurement technology and sensors. ...

Model TRIME-Ex GWs - Moisture Probe Use in Grain Drying

TRIME®-Ex GWs for quality and optimal grain and product moisture. The special thing about the TRIME® technology is that the measurement field completely penetrates the sample volume of approx. 2dm3. Therefore it not only determines data ...

CONTACT SUPPLIER -

Founded in 1972 by the actual chairman Mr. Arturo Cogliati, the Falcon S.r.l. got a steady growth till it became one of the leader companies in the field of zootechnical feeding equipment. It was the first company in 1975 which produced the chain ...

Falcon - Model Ø 45 - Low Level Broiler Feeding Plants

Three feed windows on the cone for complete and automatic filling up of the pans. Easier for the day-old chicks to go in and out the pan with the special design of the grill. Anti spill brim prevents feed wastage. With the pans on the floor, the ...

CONTACT SUPPLIER -

Ecological Laboratories Inc. is a biotechnology company that develops and manufactures novel, proprietary, liquid microbial formulations that are capable of solving many of the most challenging environmental problems facing the world today. ...

Microbe-Lift - Model HOG - Enhanced Manure Management Gal for Pig Farms

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to ...

CONTACT SUPPLIER -

Plasma Clean Air provides sustainable, cost saving solutions to the building services industry. We specialise in grease management, odour and IAQ infection control systems designed for commercial kitchens and general building ventilation. Our ...

-

Royal Eijkelkamp makes a difference worldwide by developing, producing and delivering solutions for soil and water research. Royal Eijkelkamp is involved in soil and water projects worldwide within the themes Land Degradation, Food Safety, ...

Model 04.16 - Soil Coring Kit for Chemical Soil Research

Soil sampling for the determination of the presence of very volatile components such as benzene, toluene, xylene and chlorinated hydrocarbons should be executed with samplers that prevent the sample from being exposed to air. Preferably the ...

CONTACT SUPPLIER -

At Jenfitch, Inc., we are developing water treatment chemical solutions for meeting the strenuous demands for the 21st Century. With over 40 years in the water treatment industry, we are concern with developing technologies that help solve the ...

Jenfitch - Chemical for Controlling Citrus Cankers

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the ...

CONTACT SUPPLIER -

Founded in 2010, Infitek is a professional manufacturer driven by innovation and service in laboratory and Medical field, whose brands include Infitek, and Sunoom, our company is certified by ISO9001, ISO13485 and Intellectual Property Management ...

-

Warden Biomedia specialises in the research and development of random filter media for aeration and biological treatment plants. With the philosophy of increased surface area, the eco-friendly biological filter media are manufactured with specific ...

-

Toro Equipment is a leading European company specialized in the design and manufacture of equipment for industrial and urban wastewater treatment, water processing, water reuse and sludge treatment. We offer our customers the best water treatment ...

Services

Since its beginnings, it has stood out because of a marked vocation for innovation and customer ...

CONTACT SUPPLIER -

KISTERS specialises in the collection, processing and reporting of environmental data from around the world, creating innovative and data-driven solutions that harness the power of data and technology. Founded 60 years ago and headquartered in ...

Kisters - Version VisShare - Online Collaboration and 3D CAD Data Sharing Software

Just create a project, assign people, add CAD data via drag & drop - 3D collaboration can be that easy. Now all you need to do is share a link to a single 3D CAD model or 2D drawing, or give individuals access to the entire ...

CONTACT SUPPLIER -

RunDry Evaporator, a manufacturer of high quality wastewater and machine coolant evaporators. Our electric RunDry Evaporators can dispose of your wastewater for about $ 0.25/gallon. The water tank is made of 316L stainless steel and has clean smooth ...

-

Siebtechnik Tema is our global umbrella brand of Siebtechnik GmbH and the former TEMA Group. SIEBTECHNIK TEMA is part of a globally operating group of companies with around 3,500 employees in more than 50 companies with a clear focus on the ...

SIEBTECHNIK TEMA - Double Roller Mill WS-L

The laboratory version of our two-roller mill is additionally equipped with a feed hopper, a base frame with collecting box and the control system, so that it is delivered ready for connection. Our Roller Mills have an innovative app control, a ...

CONTACT SUPPLIER

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you