Agricultural Industry Manufacturers, Suppliers & Companies

-

One of the largest suppliers of incinerators globally. Providing award-winning waste solutions across the Medical, Animal and Municipal sectors. Our standard incinerators range from 10kg/hr - 1,000kg/hr capacity. We also offer a bespoke design ...

Inciner8 - Sheep & EWE Incinerators

With landfill and rendering costs growing at an alarming rate the idea of self-owning a small capacity lamb incinerator for your own use is becoming more and more viable – especially now with our competitive range of finance options available. ...

CONTACT SUPPLIER -

Warden Biomedia specialises in the research and development of random filter media for aeration and biological treatment plants. With the philosophy of increased surface area, the eco-friendly biological filter media are manufactured with specific ...

-

Founder and company Director Shane Finnegan established Harp Renewables Ltd. in 2014 to provide a renewable and sustainable solution for the treatment of organic waste. Since that time, Harp Renewables has emerged as a global leader in thermophilic ...

Harp - Model Infusion 2021 - Soil Product Enhancer

50% of the world’s food production relies on synthetic nitrogen fertilizer. Synthetic fertilizers require large amounts of energy and industrial ammonia production, both of these activities emit large amounts of CO2. Synthetic fertilizers also ...

CONTACT SUPPLIER -

Founded in 1957, the Myron L Company is one of the leading manufacturers of water quality testing instruments in the world. Because of our commitment to customer satisfaction and product improvement, you have our assurance that any changes will be ...

Myron L® - Handheld Hydroponics Meters, Monitors and Kit

The nutrient solution and its management are the foundation of a successful hydroponics system. The function of a hydroponics nutrient solution is to supply the plant roots with water, oxygen and essential mineral elements in soluble form. ...

CONTACT SUPPLIER -

Founded in 1995, Quantek Instruments provides oxygen and carbon dioxide analyzers and solutions to food, pharmaceutical, research, educational, and government institutions worldwide. Our analyzers can be found in over 92 countries, including many ...

-

Our company was founded in 1996 by Zeynel Abidin Toptas in Ostim. Our company, which has a corporate structure that aims to provide quality products and services to its customers with continuous development in line with the participation of all our ...

Zetas - Pure Water for Aquarium

Especially those who want to feed an aquarium for the first time often ask 'how should the aquarium water be?' is looking for the answer. In this regard, it is generally recommended not to use tap water in the aquarium, and if tap water is to be ...

CONTACT SUPPLIER -

atech innovations gmbh started in Oberhausen in 1989, distributing ceramic membranes. Since 1992 we have also been very successful on the market as a manufacturer. While plant construction was initially one of our main activities, today we ...

Clarification in Sugar Cane Refining Services

atech innovations is one of the leading suppliers of ceramic membranes which are used for the clarification in sugar cane refining. Using the principle of microfiltration, stored liquid is clarified, obtaining a clear filtrate. Ceramic membranes are ...

CONTACT SUPPLIER -

Founded in 1972 by the actual chairman Mr. Arturo Cogliati, the Falcon S.r.l. got a steady growth till it became one of the leader companies in the field of zootechnical feeding equipment. It was the first company in 1975 which produced the chain ...

Falcon - Model PN280 - Drop Tubes With Pneumatic Shutter

280 mm: at the moment the longest pneumatic shutter on the market. Guarantee of a total discharge of feed. Sliding shutter in plastic or SST: elimination of the residual between the shutter and the feeding pipe. Extremely solid nylon body. All the ...

CONTACT SUPPLIER -

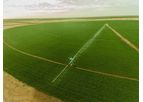

AFKO Pivot Irrigation Systems is a global leader in advanced irrigation solutions. Based in Ankara, Turkey, AFKO specializes in providing state-of-the-art irrigation systems designed to enhance agricultural productivity while conserving water ...

AFKO - Small Center Pivot Irrigation System

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus ...

CONTACT SUPPLIER -

ENERPAT Group established ENERPAT Jiangsu Environmental Protection Industry Co., Ltd. in China, and start to enter the China's. The Enerpat name has become synonymous with recycling equipment. Established in 1936 it now has a 66,000 ft main factory ...

Enerpat - Model EWS - Wood Shaving Machine EWS series

Enerpat wood shaving machine is designed to produce wood shavings in desired and suitable size. Automatic feeding method can help the production line to increase productivity, saving time and labor. ...

CONTACT SUPPLIER -

DSS Steam Trap Manufacturer was established in 2008, after noticing ongoing problems in the industrial manufacturing markets due to the failure of conventional mechanical type steam traps. These products were costly, would fail regularly and cost ...

-

Reef Industries is a plastic film & laminate manufacturer with more than 65 years of experience. Our expertise in producing quality, custom-configured final products ensure our customers’ needs are always met in a timely and professional manner. We ...

Griffolyn - Grain Covers

Protect grain from adverse weather conditions with Griffolyn® grain covers. Their reinforced polyethylene laminates can handle daily and seasonal use, year after year. This product is designed to resist tears, abrasions, the elements, and retain ...

CONTACT SUPPLIER -

With decades of experience in ultra-high-pressure technology with operating pressures of up to 4.000 bar WOMA sets standards in the construction of high-pressure plunger pumps and ultra-high-pressure units. Diesel and electrically driven WOMA ...

EcoTherm - Model 600/40 - Compact and Weight-Optimised Single-Axle Trailer

EcoTherm 600: Compact Design, high performance, highest safety. With up to 95°C hot water facades, small pipes, industrial flooring and other surfaces can be easily cleaned, oil and grease can be washed away and coating can be removed. The ...

CONTACT SUPPLIER -

Since 1905, Hilliard has been engineering, manufacturing and distributing motion control and filtration products. Our extensive history, expert knowledge of applications and strict quality standards make us a leading industry supplier. Hilliard's ...

-

With over a century of global experience Landustrie has become a leading player in the field of water and wastewater management. Our basis was laid around 1913. The company was active in the agricultural market sector and involved with polder ...

-

More than 70 years WTW. Since 2011, WTW is a brand of Xylem's company division Xylem Analytics. Xylem offers under its brand WTW the most comprehensive program of high-quality measuring devices for water analysis in the world. Their reliability, ...

-

Delux Manufacturing Company was founded in Axtell, Nebraska in 1962 and later expanded to our current headquarters in Kearney, Nebraska. Since the early days of our company, we’ve been pushing ahead of the curve to implement the best grain handling ...

Delux - Model DP Series & DPSL Series - Grain Dryer

Grain Dryer: Low Profile Design – 16’ + Legs. Single and Three Phase Models Available. Capacities Up To 1,400 BPH. Energy Efficient. Vacuum Cooled Design. Very Clean & Quiet. StayKleen Designed System in Plenum and Cooling Sections. ...

CONTACT SUPPLIER -

In 1957 we began to build and sell peristaltic pumps out of Houston, Texas. Since 1974 our pump and tubing operation have been located in Manchaca, Texas. As one of the oldest manufacturers of peristaltic pumps, Randolph has maintained a loyal ...

Randolph - Custom Extruded Flexible Profiles

Custom extruded flexible profiles are generally component parts for other manufactured products. We extrude parts for customer or industry specific applications, working closely with the customer to meet their exact ...

CONTACT SUPPLIER -

Samyang succeeded in localizing fine materials by producing ion exchange resins in Korea for the first time through a technical partnership with Japan's Mitsubishi Chemical in 1976. Samyang Fine Technology is a joint venture established and invested ...

Seratom, Seratex - Model PA - Partially-Absorbable Mesh for Transplant

Reinforces weakened tissues for symptoms of weakening soft tissues such as pelvic organ ...

CONTACT SUPPLIER -

UP Umweltanalytische Produkte GmbH is specialized in the development, production, marketing and sales of environmental analytical products in the areas of soilphysics, hydrology, plantphysiology and meteorology. We offer single measurement devices ...

Umweltanalytische-Produkte - Firmtech Eleven

Lab instrument to measure firmness and size of soft fruits like Cherries, Blueberries, Strawberries, and similar fruits. Stand-alone unit with data transmission to PC or Notebook via USB. Automatic data transfer to LIMS Fruitsoft. ...

CONTACT SUPPLIER

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you