Agricultural Industry Manufacturers, Suppliers & Companies

-

ENVEA manufactures high-precision monitoring systems as well as environmental data processing and reporting solutions with extensive knowledge in the development of complete turnkey solutions. We assist entities in complying with applicable ...

-

Gouda Geo-Equipment is a Dutch company that is specialized in the design and manufacturing of geotechnical equipment and instruments for soil investigation worldwide, such as: Cone penetration testing trucks and crawlers (onshore), Cone penetration ...

Gouda-Geo - Static Pore Pressure Meters

At Gouda Geo-Equipment, you can order our convenient static pore pressure meters. Use these to measure pore pressure in groundwater in the subsoil. The subsoil is an accumulation of multiple layers of different types of soil. Every soil type has its ...

CONTACT SUPPLIER -

Since 2004 Real Tech's vision has remained the same; to make water quality monitoring more practical, affordable and accessible for all. Provide rapid and accurate detection of water quality parameters that are important to our clients, every ...

-

Since 1905, Hilliard has been engineering, manufacturing and distributing motion control and filtration products. Our extensive history, expert knowledge of applications and strict quality standards make us a leading industry supplier. Hilliard's ...

-

Aanderaa Data Instruments develops, manufactures and markets oceanographic and meteorological instruments and special systems for collecting environmental data. Data can be stored internally in a highly protected memory or transferred in real-time ...

-

Maschinenfabrik Gustav EIRICH was founded in 1863. Originally a mill workshop, it has developed over the years into a group of companies with worldwide operations. Until today the EIRICH Group remains committed to the governing principle once ...

-

In the last decades IMKO established as leading manufacturer for TDR moisture measurement instruments. Get to know our experts for precise moisture measurement. We develop, produce and distribute state-of-the art measurement technology and sensors. ...

IMKO - Model HD2 - Trime-Pico - Mobile Reading Device for Soil Moisture Probes

You just want to quickly know how moist the delivered sand or gravel is? Or you want to check if the moisture of your material is right for the next process steps? Control your quality on-site. With the handy two-rod probe SONO-M1 and HD2 Mobile you ...

CONTACT SUPPLIER -

Toro Equipment is a leading European company specialized in the design and manufacture of equipment for industrial and urban wastewater treatment, water processing, water reuse and sludge treatment. We offer our customers the best water treatment ...

Services

Since its beginnings, it has stood out because of a marked vocation for innovation and customer ...

CONTACT SUPPLIER -

Aralab began its operations in 1985 and has since been refining the design and manufacturing of chambers where precise and reproducible environmental conditions such as temperature, humidity, light, air speed, or CO2 can be recreated. Today, it ...

Aralab - Indoor Vertical Farming Controlled Environment Chambers

State-of-the-art controlled environment chambers for Leafy Greens or Cannabis production using hydroponic irrigation and LED lighting. Our FitoClima Production Rooms provide precise control over temperature, humidity, light, CO2 levels, air ...

CONTACT SUPPLIER -

Since 1987, for over 30 years, TECNIDRO designs, develops, manufactures and markets automatic hydraulic valves and water control systems all over the world. The company founded in 1987 from Eng. Alberto Lodolo is well known all over the world for ...

-

Warden Biomedia specialises in the research and development of random filter media for aeration and biological treatment plants. With the philosophy of increased surface area, the eco-friendly biological filter media are manufactured with specific ...

-

Delta-T offers a wide range of data loggers and sensors able to measure and record hydrological, meteorological and other environmental parameters. Our products provide direct measurements of the forces and effects that renewable energy and other ...

Multi-Parameter Soil Sensor - Model WET150 - Digital SDI-12 enabled

- lower cost research-grade multi-parameter sensor - Measures moisture, temperature and EC - Digital SDI-12 for easy system integration - Rugged and low power - Accurate monitoring of soil conditions - Detachable and extendable cable system - 5 year ...

CONTACT SUPPLIER -

Founded in 1972 by the actual chairman Mr. Arturo Cogliati, the Falcon S.r.l. got a steady growth till it became one of the leader companies in the field of zootechnical feeding equipment. It was the first company in 1975 which produced the chain ...

Falcon - Model 1025 - Pig Feed Weight Dispenser

They consist in a large galvanized sheet container; the opening of the bottom permits the distribution of the feed on the floor uniformly. The regulation of the adjustable side walls allows to determine the correct amount of the feed to be ...

CONTACT SUPPLIER -

Since 1974, BESTMIX Software, formerly known as Adifo, has developed and serviced a unique range of food and feed industry-specific software tools for least-cost recipe formulation, quality data management, ration calculation, cloud services and ...

Bestmix - Recipe Management (Feed) Software

Empowering Businesses with BESTMIX Recipe Management: Setting the Benchmark for Excellence in Today's Dynamic Market. In today's dynamic market, where raw material prices, customer service expectations, and quality demands constantly challenge ...

CONTACT SUPPLIER -

Founder and company Director Shane Finnegan established Harp Renewables Ltd. in 2014 to provide a renewable and sustainable solution for the treatment of organic waste. Since that time, Harp Renewables has emerged as a global leader in thermophilic ...

Harp - Model Infusion 2021 - Soil Product Enhancer

50% of the world’s food production relies on synthetic nitrogen fertilizer. Synthetic fertilizers require large amounts of energy and industrial ammonia production, both of these activities emit large amounts of CO2. Synthetic fertilizers also ...

CONTACT SUPPLIER -

Bertin Technologies is a French industrialist in scientific instrumentation that designs and manufactures, in France and in Europe, measurement, observation & detection systems and instruments for critical applications. Every day, Bertin ...

-

Founded in 2010, Infitek is a professional manufacturer driven by innovation and service in laboratory and Medical field, whose brands include Infitek, and Sunoom, our company is certified by ISO9001, ISO13485 and Intellectual Property Management ...

Infitek - Model BA-VA-120 - Veterinary Chemistry Analyzer

BA-VA-120 Veterinary Chemistry Analyzer a completely new chemistry, electrolyte, immunoassay and coagulation analyzer for animal health diagnosis producing accurate reference laboratory quality ...

CONTACT SUPPLIER -

Eureka Water Probes, formed in 2002, is a global leader in the design and manufacture of multiparameter water quality sondes. Eureka offers the largest selection of sensor technologies for multiprobes in the industry. In addition to the latest ...

Eureka - Mini iPad

Retina display: 8.3-inch (diagonal) LED-backlit Multi-Touch display with IPS technology, 2266-by-1488 resolution at 326 pixels per inch (ppi), Wide color display (P3), True Tone display, Fingerprint-resistant oleophobic coating, Fully laminated ...

CONTACT SUPPLIER -

Reef Industries is a plastic film & laminate manufacturer with more than 65 years of experience. Our expertise in producing quality, custom-configured final products ensure our customers’ needs are always met in a timely and professional manner. We ...

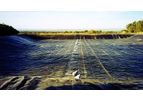

Permalon - Aquaculture Liners

Aquaculture liners require a special material to offer the balance of properties necessary to best meet those needs. Reef Industries would like to introduce Permalon®, a non-toxic polyethylene membrane ideal for lining ponds, lagoons, tanks, ...

CONTACT SUPPLIER -

Our company was founded in 1996 by Zeynel Abidin Toptas in Ostim. Our company, which has a corporate structure that aims to provide quality products and services to its customers with continuous development in line with the participation of all our ...

Zetas - Pure Water for Aquarium

Especially those who want to feed an aquarium for the first time often ask 'how should the aquarium water be?' is looking for the answer. In this regard, it is generally recommended not to use tap water in the aquarium, and if tap water is to be ...

CONTACT SUPPLIER

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you