Agricultural Industry Manufacturers, Suppliers & Companies

-

atech innovations gmbh started in Oberhausen in 1989, distributing ceramic membranes. Since 1992 we have also been very successful on the market as a manufacturer. While plant construction was initially one of our main activities, today we ...

Beer Recovery from Yeast

Rely on the quality of ceramic filtration membranes by atech innovations for beer recovery from yeast. We offer a wide range of membrane designs, ranging from single- to multi channel membranes with different diameters suitable for ultra filtration ...

CONTACT SUPPLIER -

Delta-T offers a wide range of data loggers and sensors able to measure and record hydrological, meteorological and other environmental parameters. Our products provide direct measurements of the forces and effects that renewable energy and other ...

Delta-T Devices WinDIAS - Model 3 - Leaf Image Analysis System

The recently upgraded WinDIAS 3 Leaf Image Analysis System provides fast, accurate measurement of leaf area and leaf features – making it ideal for plant pathology and phenotyping applications. WinDIAS’s analysis features are well suited ...

CONTACT SUPPLIER -

EnviTec Biogas AG covers the entire value chain for the production of biogas, including the planning and turnkey construction of biogas plants and biogas upgrading plants as well as their commissioning. The company takes charge of biological and ...

-

Royal Eijkelkamp makes a difference worldwide by developing, producing and delivering solutions for soil and water research. Royal Eijkelkamp is involved in soil and water projects worldwide within the themes Land Degradation, Food Safety, ...

Eijkelkamp - Model 14.04.04 - Jet-Fill Tensiometers

The Jet-fill tensiometer basically has the same components as the standard tensiometer but is equipped with a reservoir and a refill mechanism. At a push of the button the Jet-fill mechanism instantly injects water from the reservoir into the body ...

CONTACT SUPPLIER -

For more than 40 years, the Mosa Group has been focusing its production activity on the exchange of technical and marketing experiences between industrial sectors: “Molds“, “Stamping” and “Machines for Agriculture“. We offer a complete range of ...

Irrigation System - Tailor Made Irrigation System

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the ...

CONTACT SUPPLIER -

Since 1905, Hilliard has been engineering, manufacturing and distributing motion control and filtration products. Our extensive history, expert knowledge of applications and strict quality standards make us a leading industry supplier. Hilliard's ...

-

Challenge Technology has been the world leader in respirometic equipment since 1991. Our respirometers are trusted by scientists worldwide for wastewater treatment, biogas optimization, compost evaluation, and soil remediation. Innovation for the ...

Challenge Technology - Model AER-800S - Soil/Compost Research Respirometer

The AER-800S Research Respirometer utilizes eight specially designed reaction chambers for use with solids such as soil, compost, or plastics in biodegradability ...

CONTACT SUPPLIER -

Varicon Aqua is the manufacturer of the Phyco- range of photobioreactors and the Cell-Hi line of algal nutrients. We are based in the UK and our team has more than 30 years’ experience designing, constructing and deploying algal photobioreactors, ...

Varicon-Aqua - Instant Algae Concentrate

Instant Algae is a super-concentrated liquid microalgae feed for larval fish, shrimp, and bivalve shellfish. It is used to supplement or replace live algae grown on-site at your hatchery. Instant Algae® products are pure, phototrophically grown, ...

CONTACT SUPPLIER -

Oizom offers Environmental IoT and Environmental AI solutions for a sustainable future. Our Air Monitoring System is known for accurate environmental data using patented e-Breathing Technology. Our data analytics platform derives actionable insights ...

-

Since 1966, we've helped customers solve their toughest pumping and dredging challenges. SRS Crisafulli customers choose from a broad line of high-performance SRS Crisafulli trailer, vertical, and submersible pumps, dredges, and power units, which ...

-

Founded in 1981, the HRS Group operates at the forefront of thermal technology, offering innovative and effective heat transfer products worldwide with a strong focus on managing energy efficiently. For 40 years, HRS products and systems have been ...

HRS - Model CIP & SIP - CIP and SIP Cleaning System

HRS Heat Exchangers offers cleaning in place (CIP) and sterilisation in place (SIP) systems for cleaning and disinfection of food industry systems. Our CIP and SIP systems are supplied with a control system included, enabling automated cleaning ...

CONTACT SUPPLIER -

Eureka Water Probes, formed in 2002, is a global leader in the design and manufacture of multiparameter water quality sondes. Eureka offers the largest selection of sensor technologies for multiprobes in the industry. In addition to the latest ...

Eureka - Mini iPad

Retina display: 8.3-inch (diagonal) LED-backlit Multi-Touch display with IPS technology, 2266-by-1488 resolution at 326 pixels per inch (ppi), Wide color display (P3), True Tone display, Fingerprint-resistant oleophobic coating, Fully laminated ...

CONTACT SUPPLIER -

In 1957 we began to build and sell peristaltic pumps out of Houston, Texas. Since 1974 our pump and tubing operation have been located in Manchaca, Texas. As one of the oldest manufacturers of peristaltic pumps, Randolph has maintained a loyal ...

-

Toro Equipment is a leading European company specialized in the design and manufacture of equipment for industrial and urban wastewater treatment, water processing, water reuse and sludge treatment. We offer our customers the best water treatment ...

Services

Since its beginnings, it has stood out because of a marked vocation for innovation and customer ...

CONTACT SUPPLIER -

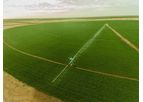

AFKO Pivot Irrigation Systems is a global leader in advanced irrigation solutions. Based in Ankara, Turkey, AFKO specializes in providing state-of-the-art irrigation systems designed to enhance agricultural productivity while conserving water ...

AFKO - Small Center Pivot Irrigation System

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus ...

CONTACT SUPPLIER -

Proco Products, Inc. is a global leader in the design and manufacturing of piping/ducting system expansion joints. We offer the most complete line of rubber and molded PFA expansion joints, fabric fan connectors, braided flexible hose assemblies and ...

-

Genesis Water Technologies, Inc. is a USA based water & wastewater treatment solution company focused on advanced, innovative and sustainable water and waste treatment system solutions with operations in the Americas, Middle East, Africa and Asia. ...

-

LIGAPAL is a company based in Cormontreuil, in the heart of CHAMPAGNE since 1964. For 57 years, LIGAPAL has been designing, manufacturing and marketing its innovative products, present in France and almost everywhere in the world, thanks to our ...

APHROMETER CAN - APHROMETER CAN

THIS APHROMETER IS FOR ALL CAN IN THE WORLD WE NEED TO HAVE YOUR TECHNICAL INFORMATIONS ABOUT YOUR CAN TO CREATE YOUR APHROMETER ...

CONTACT SUPPLIER -

Ecological Laboratories Inc. is a biotechnology company that develops and manufactures novel, proprietary, liquid microbial formulations that are capable of solving many of the most challenging environmental problems facing the world today. ...

Microbe-Lift - Model HOG - Enhanced Manure Management Gal for Pig Farms

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to ...

CONTACT SUPPLIER -

Siebtechnik Tema is our global umbrella brand of Siebtechnik GmbH and the former TEMA Group. SIEBTECHNIK TEMA is part of a globally operating group of companies with around 3,500 employees in more than 50 companies with a clear focus on the ...

SIEBTECHNIK TEMA - Double Roller Mill WS-L

The laboratory version of our two-roller mill is additionally equipped with a feed hopper, a base frame with collecting box and the control system, so that it is delivered ready for connection. Our Roller Mills have an innovative app control, a ...

CONTACT SUPPLIER

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you