Agricultural Industry Manufacturers, Suppliers & Companies

-

Cornell Pump Company in Clackamas, Oregon, is a trusted manufacturer of high-quality pumps that have been designed in the USA, manufactured in the US with imported parts, and assembled in Portland, Oregon, and Vancouver, Washington. With nearly 80 ...

Cornell - Model 4NNW - Cutter Pump

The 4NNW pump is designed with Cornell’s renowned quality and durability. It features a 4" discharge, 4" suction, single volute and two-vane impeller. Available in All Iron with the following bearing frames: F16, F16K, VC16, VF16, EM16, EM16K. ...

CONTACT SUPPLIER -

We are a leading European manufacturer of reliable industrial equipment - Made in Germany. Since our foundation in 1912, we have gained over 100 years of experience in reliable engineering solutions that work. Our high reputation and focus on the ...

Koller - Model 30-200 Long - Trolley Used for Cranless Assembly, Disassembly and Transport of Downhole Tools

Trolleys are used for cranless assembly, disassembly and transport of downhole tools or other cylindric parts. For different tool diameters, the distance between the support rollers is adjustable and for different tool lengths, the center bar is ...

CONTACT SUPPLIER -

Bertin Technologies is a French industrialist in scientific instrumentation that designs and manufactures, in France and in Europe, measurement, observation & detection systems and instruments for critical applications. Every day, Bertin ...

-

Galaxy Scientific, an industry pioneer in portable optical Near Infrared spectroscopy, is an agile innovator, enabling organizations to use the power of Near Infrared optical spectroscopy to analyze and authenticate important chemicals and ...

-

Benefitting from 68 years' experience, Kingspan Klargester offer a range of reliable wastewater and SuDS management solutions, along with expert service and maintenance. Our tried and tested Kingspan Klargester product range includes sewage ...

Klargester - Below-Ground Cesspools and Silage Tank

Our below-ground Cesspools and Silage Tanks provide a reliable solution for the collection and retention of sewage, surface water, veterinary/animal waste, firefighting reservoirs and rainwater harvesting ...

CONTACT SUPPLIER -

For more than 40 years, the Mosa Group has been focusing its production activity on the exchange of technical and marketing experiences between industrial sectors: “Molds“, “Stamping” and “Machines for Agriculture“. We offer a complete range of ...

Irrigation System - Tailor Made Irrigation System

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the ...

CONTACT SUPPLIER -

PremiumProfessional associationbased in Fargo, NORTH DAKOTA (USA)

IAIA is a forum for advancing innovation, development and communication of best practice in impact assessment. Its international membership promotes development of local and global capacity for the application of environmental assessment in which ...

-

Founded in 2002 in Lévis (Québec, Canada), Creaform is a world-class leader in 3D measurement technology as well as 3D engineering services. We develop, manufacture and distribute portable and automated 3D scanning solutions to thousands of clients ...

VXinspect - Quality Assurance Services

VXinspect helps you investigate the problems raised by QC and production by performing root cause analyses and implementing corrective actions quickly to limit ...

CONTACT SUPPLIER -

We design and manufacture world-class gas analysis systems and emission monitoring solutions to measure gaseous emissions from industrial processes, gases released from natural sources into the atmosphere, and gases present in working environments. ...

-

Warden Biomedia specialises in the research and development of random filter media for aeration and biological treatment plants. With the philosophy of increased surface area, the eco-friendly biological filter media are manufactured with specific ...

-

As Matthews Environmental Solutions expanded to include incineration equipment, waste-to-energy, and abatement, the brand changed it's name to encompass all environmental solutions, not just cremation. Matthews Environmental Solutions is a globally ...

Matthews - Model S-18 - Small Pet Cremators

The Basic Essential for Small Pet Crematories: 65 lbs. (29 kg) Per Hour Cremation Rate. 300 lbs. (136 kg) Safe Load Capacity. Individual or Communal Load Operation. Fully-automatic touch-screen control panel. ...

CONTACT SUPPLIER -

atech innovations gmbh started in Oberhausen in 1989, distributing ceramic membranes. Since 1992 we have also been very successful on the market as a manufacturer. While plant construction was initially one of our main activities, today we ...

Beer Recovery from Yeast

Rely on the quality of ceramic filtration membranes by atech innovations for beer recovery from yeast. We offer a wide range of membrane designs, ranging from single- to multi channel membranes with different diameters suitable for ultra filtration ...

CONTACT SUPPLIER -

Since 1986 Atlantis has introduced innovative products that created industry standards in the landscape and rainwater sectors worldwide. We are the inventor of the Atlantis drainage cell and flat pack modular tanks that are in use in over 90 ...

Atlantis Gro-Wall® - Model Facade - Architectural Screen for Vertical Gardens

The Gro-Wall® Façade system is an ideal product for creating beautiful architectural design elements for creative facade applications. The Gro-Wall® Façade has many applications that include privacy screening, as a trellis for ...

CONTACT SUPPLIER -

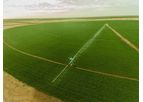

AFKO Pivot Irrigation Systems is a global leader in advanced irrigation solutions. Based in Ankara, Turkey, AFKO specializes in providing state-of-the-art irrigation systems designed to enhance agricultural productivity while conserving water ...

AFKO - Small Center Pivot Irrigation System

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus ...

CONTACT SUPPLIER -

CONSTAB – Masterbatches and Compounds for the packaging industry From heat-resistant to recyclable – highest quality for 50 years. Since decades, we are a leading partner for the plastics processing industry and are among the market leaders in ...

CONSTAB Masterbatches und Compounds - Masterbatches and Compounds for the production of cast-, calandered- and blown films.

CONSTAB Masterbatches and Compounds for the production of cast-, calandered- and blown films ensure customized ...

CONTACT SUPPLIER -

Founder and company Director Shane Finnegan established Harp Renewables Ltd. in 2014 to provide a renewable and sustainable solution for the treatment of organic waste. Since that time, Harp Renewables has emerged as a global leader in thermophilic ...

Harp - Model Infusion 2021 - Soil Product Enhancer

50% of the world’s food production relies on synthetic nitrogen fertilizer. Synthetic fertilizers require large amounts of energy and industrial ammonia production, both of these activities emit large amounts of CO2. Synthetic fertilizers also ...

CONTACT SUPPLIER -

DSS Steam Trap Manufacturer was established in 2008, after noticing ongoing problems in the industrial manufacturing markets due to the failure of conventional mechanical type steam traps. These products were costly, would fail regularly and cost ...

-

Gouda Geo-Equipment is a Dutch company that is specialized in the design and manufacturing of geotechnical equipment and instruments for soil investigation worldwide, such as: Cone penetration testing trucks and crawlers (onshore), Cone penetration ...

Gouda-Geo - Static Pore Pressure Meters

At Gouda Geo-Equipment, you can order our convenient static pore pressure meters. Use these to measure pore pressure in groundwater in the subsoil. The subsoil is an accumulation of multiple layers of different types of soil. Every soil type has its ...

CONTACT SUPPLIER -

More than 70 years WTW. Since 2011, WTW is a brand of Xylem's company division Xylem Analytics. Xylem offers under its brand WTW the most comprehensive program of high-quality measuring devices for water analysis in the world. Their reliability, ...

-

With decades of experience in ultra-high-pressure technology with operating pressures of up to 4.000 bar WOMA sets standards in the construction of high-pressure plunger pumps and ultra-high-pressure units. Diesel and electrically driven WOMA ...

EcoTherm - Model 600/40 - Compact and Weight-Optimised Single-Axle Trailer

EcoTherm 600: Compact Design, high performance, highest safety. With up to 95°C hot water facades, small pipes, industrial flooring and other surfaces can be easily cleaned, oil and grease can be washed away and coating can be removed. The ...

CONTACT SUPPLIER

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you