Actiflash - Electric Exchanger

From Technologies

Developed in collaboration with INRA (French National Institute for Agricultural research) from Villeneuve d’Ascq and EDF (French Electricity Company), the primary goal of Flash sterilization / pasteurization is to obtain - after thermal processing – products with organoleptic qualities (smell, taste, texture, vitamins) closest to fresh products (untreated).

-

Most popular related searches

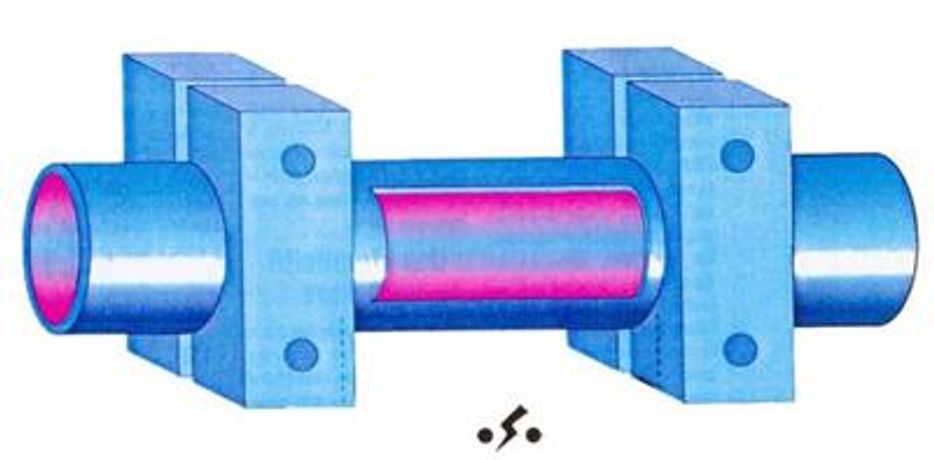

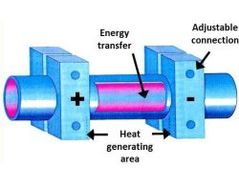

Operating Principle

The Actiflash method, derived from the Actijoule technology, consists of a series of stainless steel pipes in which the product to be treated circulates. Listed under low tension, these tubes are heated and the generated heat is directly transmitted to the product flowing inside the tubes.

Its operating principle, based on the movement of fluids at speeds greater than 6 m/s and operating at flux densities between 15 and 40 W/cm², makes Actiflash the only indirect heating method to obtain such performances.

Goals

- To respect the physical nature of products

- To keep the good taste of fresh products

- To accentuate the bacteriological safety of products

- To increase their shelf lives

Application/Industries Served

- Milk

- Milk drinks

- Cream desserts

- Fruit juices

- Wine

- Egg products (Ovoflash)

- Very smooth sauces

Advantages

- Rapid high flux heating: the direct heating without coolant fluid generates strong exchange coefficients; the holding time of the product is shorter to better preserve its original qualities

- Very accurate temperature adjustment to +/- 0.2°C

- Reduced and controlled clogging: the strict control of the product temperature and of the tube surface limits clogging and increases production times

- Absence of thermal inertia: the Actiflash can operate in “Stop & Go” because the lack of coolant removes any risk of overheating of the product

- A preserved product

- Better preservation of properties, compositions and original flavors of the products during sterilization or pasteurization

- Increase of the product shelf life:

- Removal of Maillard reactions (browning, cooked flavor)

- Limiting phenomena of proteins coagulation

- Removing losses of minerals, vitamins…

- Increase of the sterilizing or pasteurizing efficiency

- Increase of the treatment temperature

Equipment Performance

Combination of technical performance, this system, easily integrated into an existing installation, is the only method of indirect heating allowing:

- Rise times of 3.5 to 10 seconds for Delta T of 50°C (conventional method: rise time of 40 to 80 seconds for the same Delta T)

- Validated improvement of organoleptic qualities (color, taste, texture)

- Production times longer than 16 hours with a self-cleaning “Kärcher” effect due to heavy traffic speeds

- High temperature sterilization (+155°C) for milk type products and without injection of steam into the product

Customer reviews

No reviews were found for Actiflash - Electric Exchanger. Be the first to review!