Agricultural Industry Equipment

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

ShowcaseManufactured by Sutter Equipment Company, Inc.based in USA

You can build approximately 1000 ft./hr. of under 30" wide single track trails. Build trails uphill with ease and rolling dips in minutes. Pay for the SUTTER 300 Mini Trail Dozer™ in less than one season with the savings realized from decreased labor ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

PremiumManufactured by Myron L Companybased in USA

The nutrient solution and its management are the foundation of a successful hydroponics system. The function of a hydroponics nutrient solution is to supply the plant roots with water, oxygen and essential mineral elements in soluble form. ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

Dependable ± 3% soil moisture accuracy - Built in temperature measurement - Robust and buriable, with 5 year warranty. The SM150T measures soil moisture and temperature with research-grade accuracy. It offers stable, robust and reliable performance at a great price. The SM150T’s advanced patented electronics and tough build produce a highly dependable sensor with exceptional salinity ...

-

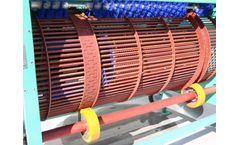

PremiumManufactured by Enerpat Groupbased in CHINA

Enerpat wood shaving machine is designed to produce wood shavings in desired and suitable size. Automatic feeding method can help the production line to increase productivity, saving time and labor. ...

-

PremiumManufactured by Cloud Tech Pvt. Ltd.based in INDIA

Cloud Tech Pvt. Ltd. is End to End customized solutions company, we believe in nature, which provides solution for Odour, Mosquitoes and bug control system, Humidification control, Outdoor and Indoor cooling, Dust Suppression, etc. We are the only company in the world that uses Natural essential oils formulation which is non toxic, biodegradable, very safe for humans. The solution is not only ...

-

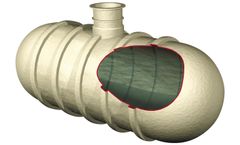

PremiumManufactured by Kingspan Klargesterbased in IRELAND

Our below-ground Cesspools and Silage Tanks provide a reliable solution for the collection and retention of sewage, surface water, veterinary/animal waste, firefighting reservoirs and rainwater harvesting ...

-

PremiumManufactured by Fiberscope.net by Medit Inc.based in CANADA

When it comes to Artificial Insemination in sheep, due to cross-pleating inside the cervix, which makes it narrow and hard to navigate, normal trans-cervical methods cannot be used to deposit a sufficient amount of sperm. Therefore, the preferred method is Laparoscopic artificial insemination (LAI). This technique bypasses the cervix, by going through the abdomen, to deposit sperm directly into ...

-

PremiumManufactured by Falcon Srlbased in ITALY

For the “Ad libitum” systems Falcon offers its chain and spiral transport systems and a wide range of drop ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Direct extraction from the silo. Chain or spiral feeding systems 0 60. No waste stainless steel cup-shaped manger. Complete ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

Washing nuts and removing shells with a single machine. The walnuts are rotated freely in the rotary drum. The bars of the rotary drum are provided with small brushes and abrasive steel particles (humps) in order to remove the raw shells from the nuts. During the peeling operation a low-pressure water stream in the interior of the drum ensures gentle cleaning. The results are clean, high-quality ...

-

PremiumManufactured by Mosa Green S.r.lbased in ITALY

The TEA 1500J and 2000J transplanters are especially designed for the connection and integration to pot fillers equipped with carousels and to all machines with a chain transport system of pots. Each gripper is individually motorized and it is possible to pick up the plants from the side. The machine parameters and the programs entered can be saved on a USB ...

-

PremiumManufactured by Farmcomp Oybased in FINLAND

Measures grain moisture content, hectolitre mass (test weight) and temperature quickly and accurately. Wile 200 measures the moisture content, test weight and temperature of grain quickly and accurately. It also guides you how to achieve the maximum precision of your measurement results, reducing the risk of under- or over-drying. You will receive your measurement results quickly, in less than 7 ...

-

PremiumManufactured by Harp Renewables Limitedbased in IRELAND

50% of the world’s food production relies on synthetic nitrogen fertilizer. Synthetic fertilizers require large amounts of energy and industrial ammonia production, both of these activities emit large amounts of CO2. Synthetic fertilizers also decompose into nitrous oxide (N2O) another ...

-

PremiumManufactured by HRS Heat Exchangers Ltd.based in UNITED KINGDOM

A modular process skid is a processing system which is contained within a frame, making it easier to transport and install. Individual skids can contain anything from a single heat exchanger and ancillaries to complete and more complex systems where the skid typically contains process equipment, controls, monitoring equipment and ancillaries. Process skids provide a ‘plug & play’ ...

-

PremiumManufactured by Ligapal Sarlbased in FRANCE

Tying twines 100% biodégradables. Each model presents a different resistance in order to provide a solution adapted to each vineyard. LIGAPAL 100% biodegradable tying twines can be used to tie vines, vegetables, climbing plants. 100% biodegradable and ecological our strings to tie, contribute to sustainable development. Our strings also help reduce waste in the ...

-

PremiumManufactured by Matthews Environmental Solutionsbased in USA

Matthews is redefining the future of pet cremation. We offer a powerful partnership that gives you access to our global resources and combines all of our engineering talents. With more than 100 years of experience and 5.000 installations in over 50 countries, we are the most trusted brand in pet cremation technology and ...

-

PremiumManufactured by Fiberscope.net by Medit Inc.based in CANADA

Medit’s veterinary Laparoscopes feature clean and crisp rigid glass lens optics coupled with durable stainless steel, and a light post with different adapters for our light sources, or pre-existing light sources you may have. These units are used for diagnostics, and procedures in the abdomen, and laparoscopic artifical insemination in sheep and other livestock. Our Laparoscopes are ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you