Agricultural Industry Equipment

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Sutter Equipment Company, Inc.based in USA

You can build approximately 1000 ft./hr. of under 30" wide single track trails. Build trails uphill with ease and rolling dips in minutes. Pay for the SUTTER 300 Mini Trail Dozer™ in less than one season with the savings realized from decreased labor ...

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

PremiumManufactured by Myron L Companybased in USA

The nutrient solution and its management are the foundation of a successful hydroponics system. The function of a hydroponics nutrient solution is to supply the plant roots with water, oxygen and essential mineral elements in soluble form. ...

-

PremiumManufactured by Falcon Srlbased in ITALY

They consist in a large galvanized sheet container; the opening of the bottom permits the distribution of the feed on the floor uniformly. The regulation of the adjustable side walls allows to determine the correct amount of the feed to be ...

-

PremiumManufactured by Ligapal Sarlbased in FRANCE

It checks the evolution of the pressure during the secondary fermentation. Before to top on the bottle put the aphrometer on the neck of the bottle. The permanent aphrometer will remain on the neck of the bottle during the entire second fermentation. A gasket ensures the airtightness between the aphrometer and the bottleneck. Stainless steel aphrometer - Manometer: (0/10) Bar, (0/6) Bar, (0/4) ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Aquaculture liners require a special material to offer the balance of properties necessary to best meet those needs. Reef Industries would like to introduce Permalon®, a non-toxic polyethylene membrane ideal for lining ponds, lagoons, tanks, raceways, or other facilities where water management is an ...

-

PremiumManufactured by Brentwood Industries, Inc.based in USA

The axial nozzles are designed as complete cone spiral nozzle consisting of a casing and an insert. Correctly assembled, the nozzles distribute the water with a spray angel of 120°, where the water flow rate depends on the operational pressure. We recommend checking the operation conditions, as nozzle distance and height have to be chosen according to the respective plant ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management. Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. DFP is a NonGMO, non-pathogenic, highly active culture and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Models P../40 (plastic shutter): P40/40 for Ø 40 pipes, P45/40 for Ø 45 pipes, P60/40 for Ø 60 pipes. Down comer pipes: Ø 40 / Ø 50. ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Reef Industries' Plastic liners play an important role in fish hatcheries and aquaculture farms by providing reliable containment for bodies of water such as ponds or tanks. These serve as a barrier that prevents water from seeping into the ground and ensures the management of water ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Quantum-HSC is a plant and soil inoculant that restores and enhances the foundational levels of soil biology (also known as the soil food web). This product incorporates heterotrophic bacteria into a diverse microbial formulation that provides unprecedented plant enhancement at foliar, root and rhizosphere. The addition of humate material to the formulation provides a readily usable carbon ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Aqua-spheres consist of small spheres (4.0 to 8mm) of magnesium hydroxide. The Aqua-spheres are used in the form of a contact bed through which the water passes. The Aqua-spheres dissolve slowly in response to acidity in the water, and during the process the pH and magnesium hardness of the water are increased. At a pH of 8.3 Aqua-spheres are insoluble in the water, as the pH becomes more acidic, ...

-

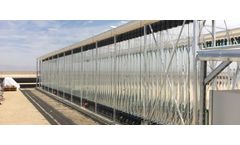

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Phyco-Lift range of photobioreactors provides a robust laboratory or pilot sized solution to growing algae for commercial or research purposes (0.07 – 2.5 m3). The simple modular design allows for scale-up with negligible performance drop; and the reactor can be operated in either airlift or column mixing configurations, both of which allow for low shear, high turbulence and high mass ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

Shaking of up to 75 trees per hour with a trunk diameter of up to 50 cm. The FSC trunk shaker is ideally suited for high trunk orchards. Using the trunk shaker, up to 75 trees per hour with diameters of up to 50 cm can be shaken. The shaker is telescopic up to 150 cm. The high trunk shaker is operated with three double-action hydraulic control devices, which must be available on the tractor. The ...

-

PremiumManufactured by Farmcomp Oybased in FINLAND

20W solar panel kit for Olli 122B, 250B+ and 450B+ energisers. The 20W solar panel kit upgrades Olli 122B, 250B+ and 450B+ for solar charging. The kit includes everything you need: 20W solar panel, adjustable stand, cables and fastening means, user instructions. ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Cell-Hi BIO is a high nitrogen N-P-K liquid fertilizer made exclusively from plant-based material, which does not contain urea. BIO is derived from a product approved for use in controlled input organic farms by the Soil ...

-

PremiumManufactured by Falcon Srlbased in ITALY

For transport systems Ø 45 and 60. Plastic shutter. Conveyor pipe: Ø ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you