Agricultural Industry Equipment

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

PremiumManufactured by Samyang Corporationbased in SOUTH KOREA

Reinforces weakened tissues for symptoms of weakening soft tissues such as pelvic organ ...

-

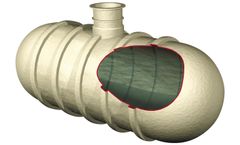

PremiumManufactured by Kingspan Klargesterbased in IRELAND

Our below-ground Cesspools and Silage Tanks provide a reliable solution for the collection and retention of sewage, surface water, veterinary/animal waste, firefighting reservoirs and rainwater harvesting ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Direct extraction from the silo. Chain or spiral feeding systems 0 60. No waste stainless steel cup-shaped manger. Complete ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Your livestock is valuable, so protect them from the elements with Griffolyn livestock curtains, made from high quality and high-performance polyethylene laminates that are internally scrim reinforced to provide high performance and long-lasting ...

-

PremiumManufactured by Ligapal Sarlbased in FRANCE

This pressure gauge checks the pressure in the champagne bottles topped on with a wire-hood and a cork. Its strong mechanism allows it to pierce the wire-hood and the cork to measure the pressure. The cork ensures the airtightness during the test. This aphrometer is very useful to check the pressure after the disgorgement of the sparkling wines Stainless steel ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

The recently upgraded WinDIAS 3 Leaf Image Analysis System provides fast, accurate measurement of leaf area and leaf features – making it ideal for plant pathology and phenotyping applications. WinDIAS’s analysis features are well suited to applications where precise colour discrimination is critical. Delta-T Devices was one of the first companies to develop leaf imaging technology ...

-

PremiumManufactured by Delux Manufacturing Companybased in USA

Grain Dryer: Fill Height – 41’ + Legs. Capacities Up To 3,300 BPH. Standard Grain Turner. Standard Exhaust Limits. Standard Service Platforms and 2 Sets of Catwalks. Large Access Doors to Plenum and Cooling Sections. Very Clean & Quiet. StayKleen Designed System in Plenum and Cooling Sections. Vacuum Cooled Design. Large Plenum Access Door. Drag Conveyor Unload Standard Over 1,500 ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Reef Industries, Inc. manufactures high-quality and high-performance polyethylene laminates and composites ideally suited for a vast array of uses in the agricultural industry. Internally reinforced and/or cross-laminated constructions provide versatile, long-lasting service in many applications. Use Griffolyn for livestock curtains, poultry curtains, greenhouse covers, hay covers or even prairie ...

-

PremiumManufactured by Atlantis International Corporation Pty Ltd.based in AUSTRALIA

Atlantis continues to progressively develop innovative products and systems to convert the concrete jungle into a sustainable Green City. The use of permeable surfaces allows rainfall to immediately soak into the ground. Rainwater can easily be harvested through underground water carriers and ...

-

PremiumManufactured by Sutter Equipment Company, Inc.based in USA

Mounted on ripper bar, 9000 lb. pull, 125' x 3/8" cable. Continuous ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

Process up to 1,500 kg of walnuts per hour. The nut blower separates empty from full nuts. Nut cores can also be separated from the shells. The Blower 1500 is suitable for dry or fresh walnuts and hazelnuts and for the dividing of chestnuts and their shells. In addition, the impulse blower divides nuts from residues such as dirt or small ...

-

PremiumManufactured by Inciner8 Limitedbased in UNITED KINGDOM

Bio security is of utmost importance in the cattle industry. A number of high profile outbreaks in recent years has started to shift opinions on managing your own fallen livestock. With landfill and rendering costs still growing now is the time to consider self-owning an incinerator for your own use – especially now with our competitive range of finance options ...

-

PremiumManufactured by AMS, Inc.based in USA

Combination Edelman Augers are used in a variety of soil conditions. They retain sandy material well, and more cohesive mud and clay soils can be easily removed from the body. A One-Piece Combination Edelman Auger is also ...

-

PremiumManufactured by Gouda Geo-Equipment B.V.based in NETHERLANDS

At Gouda Geo-Equipment, you can order our convenient static pore pressure meters. Use these to measure pore pressure in groundwater in the subsoil. The subsoil is an accumulation of multiple layers of different types of soil. Every soil type has its own unique properties resulting in stable and instable soils and individual permeability characteristics. This causes the ground water pore pressure ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

Washing and cleaning walnuts. After the harvesting, the collected nuts should be cleaned of small branches, earth, leaves, and raw shells. The washing machine for nuts is equipped with a rotary drum including stable steel bars. By using water jets in the rotary drum, an efficient cleaning is achieved. We offer various models and sizes according to the extent of the walnut ...

-

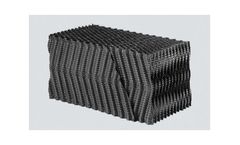

PremiumManufactured by Brentwood Industries, Inc.based in USA

For an efficient nitrification in biofilters of recirculation aquaculture system (RAS), we offer the BIOdek biofilm carrier material as cross-fluted and as vertical flow ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you