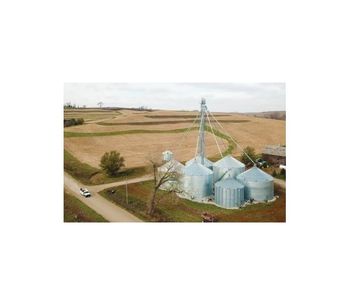

Sudenga - Bucket Elevators / Grain Legs

From Bucket Elevators

Sudenga bucket elevators are designed and built to exacting specifications giving the owner a system that will provide more years of service, with less downtime and repair. Sudenga elevator legs produce advertised capacities with extreme reliability. They offer superior construction, and go up without problems. We employ the latest advances in manufacturing technology and production methods to produce solid, reliable systems. Features all welded construction. Available with painted or hot-dipped finish.

-

Most popular related searches

Product Details

Sudenga bucket elevators offer the value added features that you and your operation demand. Our finish is an attractive, durable blue enamel, with other colors available on request. Hot dipped galvanized finish is available for ultimate long term resistance to the elements.

Trunking sections are designed to provide superb dust and weather tight protection. Sections are jigged and continuous seam welded. Angle iron or plate flanges, depending on the series, are engineered for the job and minimize overlap to prevent the trapping of corrosive moisture or product. 14, 12, and 10 gauge trunking is available. Reinforced inspection stations ensure trunk integrity when removable covers are off. Inspection ports can be positioned in four different locations by rotating the section and cover, allowing for easier ongoing inspection and maintenance.

Ladder and safety cage are standard galvanized construction. Head service platforms, distributor service platforms and OSHA rest platforms are painted or hot dipped galvanized and come assembled to save valuable time during installation.

All capacities are based on a 75% cup fill or water level plus 10%. Heavy duty polyethylene buckets resist bending, breaking and are lightweight. Bucket vents are standard. Standard SCOF (static conducting, oil resistant, flame resistant) Goodyear Pathfinder “Supreme” rubber belting is “the best there is”, and stays flexible in cold weather. PVC belting, belting for high oil exposure, and a variety of cup types are available upon request.

Standard Features

- Industrial Design

- Capacities from 175 to 40,000 BPH. Honest Capacity Ratings.

- Drum Style Head Pulleys. Holz replaceable slide lagging standard on SR 36, 42 & 48, and Hi-Cap Models 24, 30, and 48. Rubber lagging with herringbone pattern standard other sizes. All oil and fire resistant. Self-cleaning slatted boot pulley standard – all models.

- Goodyear Pathfinder Supreme rubber belting, static conducting, best for oil and flame resistance. Stays pliable in winter. Unsurpassed for feed mill use.

- Double row spherical roller pillow block bearings standard on Medium “24” and larger legs, pillow block ball bearings on Model “C” 6” and Model “12” Junior legs. Split bearings available for easy replacement

- Turned, ground, and polished head and boot shafts, for guaranteed true dimension and straightness.

- Durable polyethylene vented cups standard for better cup fill and discharge; increased venting available for light or hard to handle products. Nylon available.

- Hinged and gasketed inspection ports, with screens for safety, removable for service access.

- Trunking section lengths in 2’ increments allow desired discharge height.

- Trunking inspection port can be located in 4 locations for operator visibility.

- Metal backed urethane or rubber lined discharge and transition standard on 36” diameter and larger, optional on smaller units.

- Pre-welded platforms make for easy and quick assembly. Lifting eyes on head sections are standard. Jacking bolts for head shaft alignment standard on 24” and larger.

- Jig assembled and continuous welded construction for superior durability and hassle free installation. Heavy plate trunking flanges standard on most sizes.

- Phosphatized, primed, and painted with a 2-part polyurethane paint. Blue paint standard. White, red, or gray optional at no charge. Hot dipped galvanized construction optional. Read more about our finish types here.

- A variety of accessories are available along with support towers, catwalk, trussing kits, spouting and distributors.

- Backed by a company with over 125 years of experience.

Customer reviews

No reviews were found for Sudenga - Bucket Elevators / Grain Legs. Be the first to review!