Agricultural Industry Equipment

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

PremiumManufactured by Myron L Companybased in USA

The nutrient solution and its management are the foundation of a successful hydroponics system. The function of a hydroponics nutrient solution is to supply the plant roots with water, oxygen and essential mineral elements in soluble form. ...

-

PremiumManufactured by Falcon Srlbased in ITALY

FALCON Spiral transport systems, simple and reliable to use, allow a greater choice in any situation. The spiral moves the material along the pipeline at high speed. The flexibility of the spiral enables it to be installed in many configuration, not necessary ...

-

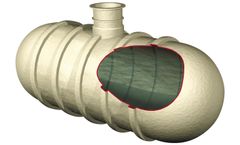

PremiumManufactured by Kingspan Klargesterbased in IRELAND

Our below-ground Cesspools and Silage Tanks provide a reliable solution for the collection and retention of sewage, surface water, veterinary/animal waste, firefighting reservoirs and rainwater harvesting ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Instant Algae is a super-concentrated liquid microalgae feed for larval fish, shrimp, and bivalve shellfish. It is used to supplement or replace live algae grown on-site at your hatchery. Instant Algae® products are pure, phototrophically grown, highly-concentrated marine microalgae. The whole-cell algae are non-viable but intact, retaining all their nutritional value, with no need to ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Phyco-Pond is a high rate algal pond (HRAP) manufactured by Varicon Aqua according to optimised geometric considerations which impact rate of mixing, photosynthetic efficiency, power consumption and biomass yield. Smaller systems are fabricated from a fibre glass mould, whilst larger systems comprise of a levelled and compacted solid matrix, onto which an impermeable geotextile is overlaid. ...

-

PremiumManufactured by Falcon Srlbased in ITALY

FALCON chain transport systems, thanks to its flexibility, can carry out very tortuous vertical and horizontal circuits, difficult to achieve with traditional screw conveyors. You can get a system with a maximum capacity of 12 tons / hour, with a very low power, ranging from 1.5 to 4 HP per circuit. Con lo stesso trasportatore, si possono collegare uno o più silo di prelievo e distribuire ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Composed of a drop tube with plastic shutter and a stainless steel feed-type selector switch. They can delivery from 2 to 5 different types of feed, with only one ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

The DL6 is a dedicated data logger optimised for use with Delta-T soil moisture sensors. It can be used with combinations of ThetaProbes, SM150 Soil Moisture Sensors, SM300 Soil Moisture Sensors and Profile Probes, and also accepts rain gauge and soil temperature probe inputs. Up to 16000 readings can be stored in ...

-

PremiumManufactured by Ligapal Sarlbased in FRANCE

The simplified Aphrometer is designed to check the pressure and the vacuum in the bottles of still wine (Bordeaux bottles, Burgundy bottles). Thanks to its sting this pressure gauge pierces corks and some synthetic corks, but it cannot pierce the crown caps or all other metallic ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

A unique proprietary consortium that features select photosynthetic microorganisms and natural growth factors that drive plant energy function. This microbial consortium maximizes plant photosynthesis and increases additional reserve energy from nutrients, carbon, and light. Quantum-Light contains no humic component. This breakthrough technology is the core discovery in the Quantum Growth ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Specially formulated to keep farm retention and irrigation ponds clean and clear. The specialized bacteria in PBL and HCSC have been chosen to naturally eliminate organic waste and sludge while improving water quality and reducing nitrate compounds and phosphates. These undesirable compounds can lead to unwanted algae and weed growth. MICROBE-LIFT® bacterial products are safe for people, ...

-

PremiumManufactured by Enerpat Groupbased in CHINA

Enerpat wood shaving machine is designed to produce wood shavings in desired and suitable size. Automatic feeding method can help the production line to increase productivity, saving time and labor. ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Quantum-Organic Total is a plant and soil inoculant that restores and enhances the foundational levels of soil biology (also known as the soil food web). This product incorporates highly specialized photosynthetic and heterotrophic bacteria into a diverse microbial formulation that provides unprecedented plant enhancement at foliar, root and ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Reef Industries, Inc. manufactures high-quality and high-performance polyethylene laminates and composites ideally suited for a vast array of uses in the agricultural industry. Internally reinforced and/or cross-laminated constructions provide versatile, long-lasting service in many applications. Use Griffolyn for livestock curtains, poultry curtains, greenhouse covers, hay covers or even prairie ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Cell-Hi BIO is a high nitrogen N-P-K liquid fertilizer made exclusively from plant-based material, which does not contain urea. BIO is derived from a product approved for use in controlled input organic farms by the Soil ...

-

PremiumManufactured by UP Umweltanalytische Produkte GmbHbased in GERMANY

The refractometer is a measuring device for determining the refractive index of - liquid or solid - transparent materials by refractometry. It uses the behavior of light at the interface between a prism with known properties and the substance under test. If the general composition of a liquid is known, a refractometer can be used to measure the concentration. In connection with the harvesting of ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you