Agricultural Industry Equipment

-

ShowcaseManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

PremiumManufactured by Aralabbased in PORTUGAL

Reach-in environmental simulation plant growth chambers designed for diverse applications in biotechnology and plant research. With unparalleled control over temperature, humidity, airflow, and photoperiod, these chambers offer a range of options to cater to nearly any research ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

The ML3 ThetaKit provides researchers with a portable tool for highly accurate, near instantaneous measurement of moisture levels in soils and substrates. The ThetaKit is easy to use. Simply switch the connected HH2 Moisture Meter on, insert the probe pins fully into the soil, and press the HH2’s “read” button to display the moisture measurement. Readings can then be stored with ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

A wide-ranging microbial consortium, which includes the core technology of both Quantum-Light and Quantum-HSC, along with additional spore-forming microbes selected for their ability to breakdown accumulated organics, such as thatch, black layer, and detritus. Through this breakdown process, the nutrients within the material are released and available for plant ...

-

PremiumManufactured by Matthews Environmental Solutionsbased in USA

The Matthews Environmental Solutions range of Surefire SA fixed hearth pet cremators are internationally acclaimed as the most effective and environmentally responsible pet cremator systems available today. They are also highly regarded for the quality and respect they afford to each individual pet owner. The horizontal cylindrical design offers the strongest possible refractory construction ...

-

PremiumManufactured by Ligapal Sarlbased in FRANCE

Allows the reel to be unwound via the upper or lower ...

-

PremiumManufactured by Cloud Tech Pvt. Ltd.based in INDIA

Cloud Tech Pvt. Ltd. is End to End customized solutions company, we believe in nature, which provides solution for Odour, Mosquitoes and bug control system, Humidification control, Outdoor and Indoor cooling, Dust Suppression, etc. We are the only company in the world that uses Natural essential oils formulation which is non toxic, biodegradable, very safe for humans. The solution is not only ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

PAR Quantum Sensor- High quality silicon photodiode, in a rugged waterproof housing. Available in 2 cable lengths: 5m cable (QS5-05) and 10m cable ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

The SunScan Canopy Analysis System uses field measurements of Photosynthetically Active Radiation (PAR) in crop canopies to provide valuable information about Leaf Area Index (LAI) and biomass production. The SunScan canopy analyser is optimised for low regular canopies such as most agricultural crops. The 1m probe enables rapid spatial averaging of large areas and PAR mapping for non-uniform ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

The WET Sensor has crucial applications in precision horticulture and soil science research and is usable in both soils and growing substrates. It is exceptional in its ability to measure pore water conductivity (ECp), the EC of the water that is available to the ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Quantum-Organic Light is a plant and soil inoculant that restores and enhances the foundational levels of soil biology (also known as the soil food web). This product incorporates highly specialized photosynthetic and heterotrophic bacteria into a diverse microbial formulation that provides unprecedented plant enhancement at foliar, root and rhizosphere. An OMRI certified version of our unique ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Varicon Aqua automated continuous rotifer system for marine hatcheries are made with industrial grade components and has been designed to function optimally by using concentrated algae pastes as the primary feed substrate. The system can operate with combinations of feed substrate including formulated diets, however the use of higher percentages of concentrated algae will prolong the periods ...

-

PremiumManufactured by AMS, Inc.based in USA

The AMS Brown Moisture Probe is a modified tile probe used primarily by agricultureal scientists and farmers to survey soil to depths of about 3-ft for the purpose of determining the depth of soil moisture storage following irrigation. The probe offers visual confirmation of soil moisture conditions, and this data is used to help determine crop yield goals, planting decisions, irrigation water ...

-

PremiumManufactured by Royal Eijkelkampbased in NETHERLANDS

Soil moisture sensor Thetaprobe ML3. Measuring range 0-50% vol. Accuracy +/- 1%. With 4 pins, length 60 mm, Ø 3.2 mm. Output signal 0-1 Vdc. Inclusive temperature meter range -20...+60 °C, accuracy +/- 0.5 °C over 0...40 °C. Exclusive cable. Warranty 5 ...

-

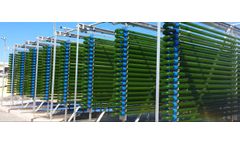

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Phyco-Flow photobioreactor is an innovative serpentine system that scales easily to meet increased production requirements at both pilot and commercial scales (0.6 – 30 m3 in volume). This configuration has superseded our BioFence photobioreactor and offers numerous operational improvements. This includes lower capital and operational costs, and reduced shut down time via an integrated ...

-

PremiumManufactured by AMS, Inc.based in USA

Two different styles to choose from. Soil ejectors help you remove samples from your probe with ease and keep your fingers clean! The old style ejectors snap inside the slot of the probe and slide up as the sample enters the probe. They are fixed ejectors and are meant to stay inside of the slot of the probe for subsequent use. (*Only available for 7/8” soil probes). The new style ejectors ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you