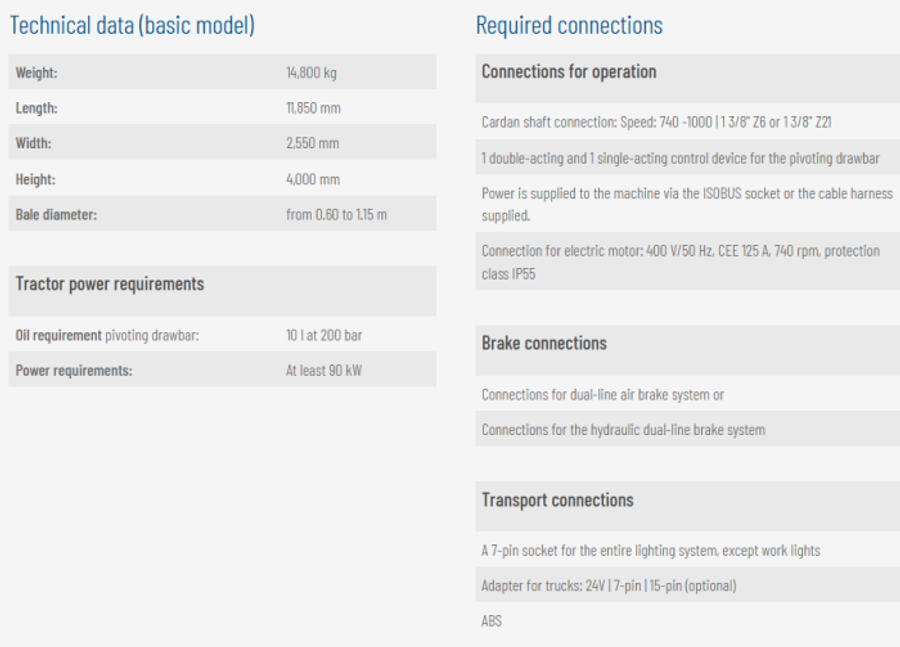

Göweil - Model LT-Master F115 - Silage Baler Wrapper Combination

From Baler and Wrapper Combination

The LT-Master is the number one baler-wrapper combination for round bales. It can be used to process not only corn silage, but also CCM, alfalfa, hemp, sugar beet pulp, grain, compound feed, and many other materials, into perfectly compressed and wrapped round bales. Fast, simple, and fully automatic. Every last detail contributes to an optimum material flow, ensuring that the LT-Master F115 delivers top-class throughput performance. The high compression of the feed is top priority along with a rapid air-tight seal and a clean production process. Compaction rates of between 30% and 70% can be achieved depending on the size and structure of the material.

-

Most popular related searches

Customer reviews

No reviews were found for Göweil - Model LT-Master F115 - Silage Baler Wrapper Combination. Be the first to review!