Agricultural Industry Equipment

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

PremiumManufactured by Harp Renewables Limitedbased in IRELAND

50% of the world’s food production relies on synthetic nitrogen fertilizer. Synthetic fertilizers require large amounts of energy and industrial ammonia production, both of these activities emit large amounts of CO2. Synthetic fertilizers also decompose into nitrous oxide (N2O) another ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Protect your poultry from the elements with Griffolyn poultry barn curtains. Griffolyn materials are high quality and high-performance polyethylene laminates that are internally reinforced to provide versatile, long-lasting service. With multiple layers and internal reinforcement, Griffolyn® resists punctures and tears. It is also cold-crack resistant to eliminate failures in cold ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Feed Pans: Day-Old Chicks: Three feed windows on the cone for complete and automatic filling up of the pans. Easier for the day-old chicks to go in and out the pan with the special design of the grill. Anti spill brim prevents feed wastage. With the pans on the floor, the windows of the drop tube open automatically. Fresh feed is always presented to the chickens. Windows completely open in any ...

-

PremiumManufactured by Kingspan Klargesterbased in IRELAND

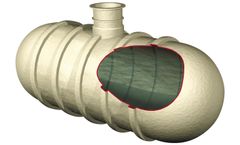

Our below-ground Cesspools and Silage Tanks provide a reliable solution for the collection and retention of sewage, surface water, veterinary/animal waste, firefighting reservoirs and rainwater harvesting ...

-

PremiumManufactured by Falcon Srlbased in ITALY

For the “Ad libitum” systems Falcon offers its chain and spiral transport systems and a wide range of drop ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Cell-Hi JWP is a Jaworski freshwater specific 100% soluble All-in-One powder used extensively in freshwater aquaculture. Cell-Hi JWP All-in-One contains all the essential macro-nutrients, micronutrients and vitamins for freshwater microalgal growth. It is the only fully soluble All-in-One product based on Jaworski’s formula available on the ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Cell-Hi BIO is a high nitrogen N-P-K liquid fertilizer made exclusively from plant-based material, which does not contain urea. BIO is derived from a product approved for use in controlled input organic farms by the Soil ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Varicon Aqua Concentrator-A ( or C-A ) has been designed with the highest industrial grade components to ensure a durable quality build. All materials are tested and tried to withstand the corrosive environment found in marine hatcheries. The harvester is fitted with a woven 316L stainless steel mesh which incorporates a dual air curtain diffuser system designed to accelerate the passage of ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

Stomatal aperture is the dominant factor in the diffusion conductance of leaf surfaces, which controls both the water loss from plant leaves and the uptake of CO2 for photosynthesis. Measurements of diffusion conductance are therefore important indicators of plant water status and provide a valuable insight into plant growth and plant adaptation to environmental ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Cell-Hi F2P is a Guillard F/2 saltwater specific 100% soluble All-in- One powder used extensively in marine aquaculture. Cell-Hi F2P All-in-One contains all the essential macro-nutrients, micro-nutrients and vitamins for microalgal growth. It is the only fully soluble All-in-One product based on Guillard F/2 available on the market; with identical N, P, trace element and vitamin ...

-

PremiumManufactured by Fiberscope.net by Medit Inc.based in CANADA

Depending on the length, width and other attributes, an examination of particular organs, orifices, passages and cavities requires endoscopic tools of varying characteristics. They may vary in diameter, working length, field of view, direction of view, and presence of sheath for one or more working channels, to name just a few. In some cases one instrument can cover a few fields of endoscopic ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

MICROBE-LIFT/AOE-P utilizes biotechnology to maintain a cleaner, healthier environment for poultry houses and yards. Poultry manure is very high in nitrogen content, a factor which leads to the emission of high concentrations of ammonia when litter becomes increasingly fouled. As a result, toxic concentrations of ammonia can build up in poultry houses. Typically, ventilation is utilized to remove ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

We can supply live algal cultures in a variety of formats, from agar plates to multiple litres of volume. This service will save the end user having to sub-culture master stocks in the ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

Shake up to 75 trees per hour with a maximum diameter of 60cm with the trunk shaker VHY. The powerful trunk shaker also reduces pressure points on the trees. The shaker is equipped with an electric control and an oil ...

-

PremiumManufactured by Avecom NVbased in BELGIUM

Experience the innovative solution to your protein needs with Avecom's EXIMIUM®. Whether you’re tackling the increasing demand for proteins or simply looking for a high-quality protein source, EXIMIUM® offers a versatile solution with its naturally formulated, protein-rich animal ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you