Agricultural Industry Equipment

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by Sutter Equipment Company, Inc.based in USA

You can build approximately 1000 ft./hr. of under 30" wide single track trails. Build trails uphill with ease and rolling dips in minutes. Pay for the SUTTER 300 Mini Trail Dozer™ in less than one season with the savings realized from decreased labor ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Features: For Æ 60 transport systems. Capacity: 7 liters. Transparent container in Polypropylene. Porthole for clearing. The ball which opens the dispenser guarantees a smooth action to give simultaneous distribution of all the feed from each dispenser. Cord in stainless steel. Possibility of exclusion of each dispenser by single shutter. Can be supplied ...

-

PremiumManufactured by Falcon Srlbased in ITALY

They consist in a large galvanized sheet container; the opening of the bottom permits the distribution of the feed on the floor uniformly. The regulation of the adjustable side walls allows to determine the correct amount of the feed to be ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Composed of a drop tube with plastic shutter and a stainless steel feed-type selector switch. They can delivery from 2 to 5 different types of feed, with only one ...

-

PremiumManufactured by Falcon Srlbased in ITALY

FALCON chain transport systems, thanks to its flexibility, can carry out very tortuous vertical and horizontal circuits, difficult to achieve with traditional screw conveyors. You can get a system with a maximum capacity of 12 tons / hour, with a very low power, ranging from 1.5 to 4 HP per circuit. Con lo stesso trasportatore, si possono collegare uno o più silo di prelievo e distribuire ...

-

PremiumManufactured by Falcon Srlbased in ITALY

For transport systems Ø 60, 63, 75 e 90. Metal shutter adjustable from distance. Conveyor pipe: Ø ...

-

PremiumManufactured by Fiberscope.net by Medit Inc.based in CANADA

Depending on the length, width and other attributes, an examination of particular organs, orifices, passages and cavities requires endoscopic tools of varying characteristics. They may vary in diameter, working length, field of view, direction of view, and presence of sheath for one or more working channels, to name just a few. In some cases one instrument can cover a few fields of endoscopic ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

Cell-Hi JWP is a Jaworski freshwater specific 100% soluble All-in-One powder used extensively in freshwater aquaculture. Cell-Hi JWP All-in-One contains all the essential macro-nutrients, micronutrients and vitamins for freshwater microalgal growth. It is the only fully soluble All-in-One product based on Jaworski’s formula available on the ...

-

PremiumManufactured by Falcon Srlbased in ITALY

The FALCON System first in the world uses a chain conveyor that has plastic discs moulded to the chain at regular interval. The chain conveyor moves in a continuous circuit the material at high speed. The flexibility of the chain enables it to be installed in almost any ...

-

PremiumManufactured by Mosa Green S.r.lbased in ITALY

Automatic potting machine with dibble system for single pots. Pots destacker, dibble system and exit conveyor. Pot diameter from 8 cm to 22 ...

-

PremiumManufactured by Mosa Green S.r.lbased in ITALY

Electronic small double drum seeder with electronic controls, double vacuum pump 1,5 ...

-

PremiumManufactured by UP Umweltanalytische Produkte GmbHbased in GERMANY

Easy-to-use size-measurement-device for diameters up to 100 mm. Can be used in conjunction with the FTA GS15 / 25 devices or a specific data ...

-

PremiumManufactured by Mosa Green S.r.lbased in ITALY

Soil block maker with sowing bar or sowing ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

MICROBE-LIFT/Nutri-Pack contains the full complement of essential minerals and micronutrients required by almost all beneficial microorganisms, especially nitrifying and denitrifying bacteria. By assuring that these beneficial microorganisms are not deficient in any essential minerals or micronutrients, the beneficial bacteria and other microorganisms in your pond, lagoon or wastewater system ...

-

PremiumManufactured by Fiberscope.net by Medit Inc.based in CANADA

ED-Cam portable endoscopy camera system is a great visual diagnostic device that was designed to make veterinary endoscopy procedures fast, efficient and easy. Its portable image HUB with a 7" color LCD display and a high resolution CCD camera can be connected to almost any flexible or rigid endoscope by means of a focusable video coupler. The whole system is very light (only 975 gr), versatile, ...

-

PremiumManufactured by AMS, Inc.based in USA

The AMS Hammer-Head Soil Probe Kit features a 16"L hammer-head cross handle which can be hammered on with the (included) impact absorbing dead blow hammer. No need to lug around a heavy slide hammer anymore! A standard 10” cross handle with rubber grips also comes in the kit for regular soil conditions. Probe measures 7/8"-dia. x 33"L and is constructed of nickel plated chrome molybdenum. ...

-

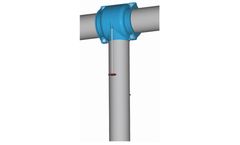

PremiumManufactured by BBA Pumps BVbased in NETHERLANDS

A multifunctional 6" inch tractor-driven manure pump for the agricultural sector. For pumping liquid slurry, ditch water or simply for irrigation. The B140 is a self-priming pump with a large solids passage, a lot of capacity, as well as significant pressure. Just fill the pump housing with water and the tractor’s PTO will do the rest. The B140 centrifugal pump comes standard with a ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you