Agricultural Industry Equipment

-

ShowcaseManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Our hi-count (20B-CFU/g) is a highly mobile, feed additive and water treatment product formulated to promote the production of healthy shrimp and fish. Microbe-Lift / DFM Microbial Blends are a cost effective and environmentally friendly option to manage Aquaculture Systems that often struggle with the overstocking of farms and the creation of excess waste. There is a strong correlation between ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Phyco-Pond is a high rate algal pond (HRAP) manufactured by Varicon Aqua according to optimised geometric considerations which impact rate of mixing, photosynthetic efficiency, power consumption and biomass yield. Smaller systems are fabricated from a fibre glass mould, whilst larger systems comprise of a levelled and compacted solid matrix, onto which an impermeable geotextile is overlaid. ...

-

PremiumManufactured by Falcon Srlbased in ITALY

FALCON Spiral transport systems, simple and reliable to use, allow a greater choice in any situation. The spiral moves the material along the pipeline at high speed. The flexibility of the spiral enables it to be installed in many configuration, not necessary ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Formulated specifically for the removal of organic bottom or surface solids that are slow to degrade. Provides rapid, natural sludge and muck removal and works 80% faster than competitive products. Binds phosphate and helps with the liquification and nutrient enhancement of manure. Organic and microbial based. MICROBE-LIFT/ SA-O is designed to be used with ...

-

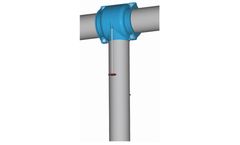

PremiumManufactured by Falcon Srlbased in ITALY

For transport systems Ø 60, 63, 75 e 90. Metal shutter adjustable from distance. Conveyor pipe: Ø ...

-

PremiumManufactured by Falcon Srlbased in ITALY

The FALCON System first in the world uses a chain conveyor that has plastic discs moulded to the chain at regular interval. The chain conveyor moves in a continuous circuit the material at high speed. The flexibility of the chain enables it to be installed in almost any ...

-

PremiumManufactured by Fiberscope.net by Medit Inc.based in CANADA

Medit’s veterinary Laparoscopes feature clean and crisp rigid glass lens optics coupled with durable stainless steel, and a light post with different adapters for our light sources, or pre-existing light sources you may have. These units are used for diagnostics, and procedures in the abdomen, and laparoscopic artifical insemination in sheep and other livestock. Our Laparoscopes are ...

-

PremiumManufactured by Falcon Srlbased in ITALY

For transport systems Ø 45 and 60. Conveyor pipe: Ø ...

-

PremiumManufactured by Falcon Srlbased in ITALY

General Characteristics: 15 kilogramme capacity. Stainless steel scale and transparent acrylic container. Simple and fast feed quantity regulation. Automatic and simultaneous opening of all ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

With these machines, a noticeable increase in shaking performance is achieved and this means a significant reduction in harvesting costs. With the mechanical trunk shaker, you can shake up to 200 trees per hour. Our mechanical trunk shaker is easy to operate, suited for juice fruit orchards, and is distinguished by a particularly bark-safe gripper. The mechanical trunk shaker is distinguished by ...

-

PremiumManufactured by Farmcomp Oybased in FINLAND

Olli 9.07S – easily movable solar-powered fence energiser. Olli 9.07S is a handy solar energiser set that includes everything you need: The energiser, a 12V/12Ah gel battery, a 6W solar panel, and an mains adapter with which you can not only charge the battery, but also use the energiser without a battery. The package also includes an earthing spike. 0.71J output energy. The easily movable ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Falcon dispensers, strong and resistant, are available in a vast number of models: with our chain and spiral transport systems, they can satisfy all feeding ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Cell-Hi range of algal cultivation medium provides all the necessary nutrients, trace elements and vitamins stabilised within a formulation that when re-constituted provides everything needed for optimal algal growth. Use the powdered medium according to the Cell-Hi product sheet. Thereafter, the soluble powder can be stored in a cool dark place or refrigerator for many months. For advanced ...

-

PremiumManufactured by Royal Eijkelkampbased in NETHERLANDS

Eijkelkamp Smart AGR Stackable manure | Hydraulic suspension 160 bar, for truck with semitrailer, complete set consisting of the Smart AGR basic, including app and service subscription, car holder, car charger 12/24 V, case, Smart AGR cabin unit, Smart AGR trailer unit and Smart AGR hydraulic sensor 160 bar (exclusive mounting ...

-

PremiumManufactured by SIEBTECHNIK GMBHbased in GERMANY

The laboratory version of our two-roller mill is additionally equipped with a feed hopper, a base frame with collecting box and the control system, so that it is delivered ready for connection. Our Roller Mills have an innovative app control, a continuously adjustable roller gap, a reversible overload protection, a high force transmission into the moving crushing roller and a suction connection. ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you