Leistritz - Model L3 Series - Screw Pumps

From Pump Technology

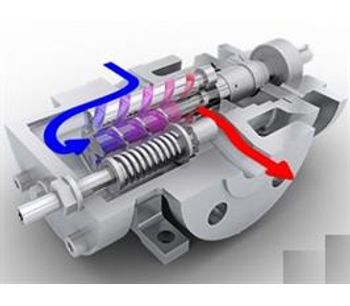

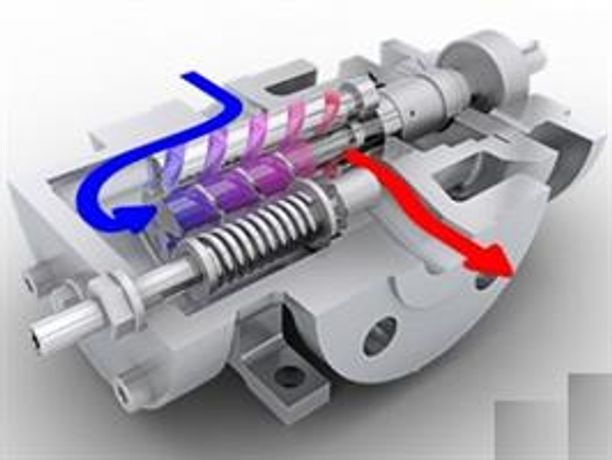

BACK TO PUMP TECHNOLOGY PRODUCTS A simplified three rotor screw pump with total hydraulic balancing and built-in relief valve as standard features. The cartridge-style pump models are simple to maintain and allows customized pump casings for direct fit replacement of older pumps.

Typical Applications

- Crude Oil

- Asphalt

- Asphalenes, Pitch & Tar

- Lube Oil

- Light & Heavy Fuel Oil

- Kedrosene

- Residuals

- Vacuum Bottoms

Performance Data

- Flow: 3-1,600 gpm

- Diff. Pressure: 2,300 psi (max)

- Viscosity: 1.2-5,000 cSt

- Temperature: 5-360° F

Scope of Supply

- Mounting: Horizontal (foot & flange) or Vertical (pedestal & deepwell)

- Bearing: Internal (product lubricated) or External (permanently grease packed)

- Seal: Packing, Lip, Single Mechanical, Mag Drive (Quench or Heating optional)

Customer reviews

No reviews were found for Leistritz - Model L3 Series - Screw Pumps. Be the first to review!