Agricultural Industry Equipment

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

MICROBE-LIFT/Nutri-Pack contains the full complement of essential minerals and micronutrients required by almost all beneficial microorganisms, especially nitrifying and denitrifying bacteria. By assuring that these beneficial microorganisms are not deficient in any essential minerals or micronutrients, the beneficial bacteria and other microorganisms in your pond, lagoon or wastewater system ...

-

PremiumManufactured by Brentwood Industries, Inc.based in USA

Excellent Cooling Capacities: For high productivity in livestock breeding it is becoming more and more important to respond to the specific requirements of the species involved. This includes controlling air temperature in the stables. The air in stables needs cooling particularly in regions where high temperatures prevail. To this end, an evaporative condenser is used to humidify and cool the ...

-

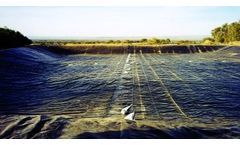

PremiumManufactured by Reef Industries, Inc.based in USA

Reef Industries' Plastic liners play an important role in fish hatcheries and aquaculture farms by providing reliable containment for bodies of water such as ponds or tanks. These serve as a barrier that prevents water from seeping into the ground and ensures the management of water ...

-

PremiumManufactured by Fiberscope.net by Medit Inc.based in CANADA

This Veterinary Video Gastroscope has been designed to perform diagnostic procedures and postoperative examinations in the stomach and colon of cats and ...

-

PremiumManufactured by Falcon Srlbased in ITALY

They consist in a large galvanized sheet container; the opening of the bottom permits the distribution of the feed on the floor uniformly. The regulation of the adjustable side walls allows to determine the correct amount of the feed to be ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Aquaculture liners require a special material to offer the balance of properties necessary to best meet those needs. Reef Industries would like to introduce Permalon®, a non-toxic polyethylene membrane ideal for lining ponds, lagoons, tanks, raceways, or other facilities where water management is an ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Your livestock is valuable. Protect them from the elements with Griffolyn® barn curtains and reusable barn covers. Griffolyn® materials are high quality, high-performance polyethylene laminates that are internally reinforced and UV stabilized to provide versatile, long-lasting service. No matter how large or small, Griffolyn® barn curtains can be fabricated to your exact ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Armorlon fumigation covers are an effective containment method when fumigating. Armorlon® fumigation tarps can be custom fabricated to your exact requirements including fitted sizes or flat heavy-duty tarps fabricated with tie-down fixtures such as grommets, D-rings, webbing straps, pipe loops, drawstrings or other features. We are a fumigation cover manufacturer who focuses on making tarps ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

MICROBE-LIFT/Professional Blend Liquid is a blend of microbes that contain specially formulated strains of bacteria manufactured for use by landscape, irrigation & pond ...

-

PremiumManufactured by Matthews Environmental Solutionsbased in USA

The Basic Essential for Small Pet Crematories: 65 lbs. (29 kg) Per Hour Cremation Rate. 300 lbs. (136 kg) Safe Load Capacity. Individual or Communal Load Operation. Fully-automatic touch-screen control panel. ...

-

PremiumManufactured by Gouda Geo-Equipment B.V.based in NETHERLANDS

At Gouda Geo-Equipment, you can order our convenient static pore pressure meters. Use these to measure pore pressure in groundwater in the subsoil. The subsoil is an accumulation of multiple layers of different types of soil. Every soil type has its own unique properties resulting in stable and instable soils and individual permeability characteristics. This causes the ground water pore pressure ...

-

PremiumManufactured by KISTERSbased in GERMANY

EnviroPro are fully encapsulated soil sensors for meaningful crop selection, irrigation and fertilisation decision making. The multi-function and multi-level subsurface instruments offer continuous reliable and repeatable monitoring of soil moisture, temperature and salinity (EC)*. With salinity and temperature compensated moisture readings, EnviroPro soil probes provide accurate data for better ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

The Rollblitz medium can be used for ball-shaped objects of 2 to at most 5 cm diameter. With the pick-up device, fallen fruit can be picked up easily and conveniently without bending over or crouching. Buying the Rollblitz also supports our cooperation with people with disabilities. The Rollblitz is a product Made in Germany made of high-quality components. The wires of the picking ball are made ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

With the economical fruit sorting trolley FCK, separate up to 2 tonnes of fruit per hour. The Fruit cleaning trolley FCK is the smallest of our fruit sorting trolleys. With a bunker volume of 620 l, up to 2 tonnes can be sorted per hour via the sorting trolley. Thanks to its compact size and weight, it can be operated without a separate drive. The fruit cleaning trolley FCK is available with a ...

-

PremiumManufactured by Aralabbased in PORTUGAL

Optimized growth rooms for precision plant production, ensuring superior environmental control. Designed for growing leafy greens, optimizing yield in a precisely controlled ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you