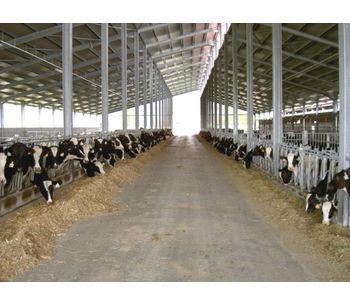

Sperotto - Cow Sheds

From Prefabricated Sheds for Livestock

Sperotto S.p.A. produces different types of prefabricated sheds for livestock. Every detail of our products is studied carefully in order to guarantee high quality and efficiency.

-

Most popular related searches

Product Details

Our prefabricated sheds are delivered to the construction site ready to be assembled and comply with the harmonized European standard EN 1090-1:2009+A1:2001. The galvanization process guarantees a long-lasting durability as the structure is coated with an anti-corrosive and anti-rust protection.

SPEROTTO steel structures are produced in different sizes, according to our customers' needs:

- width from 10 m up to 32 m;

- snow load from 60 kg/m² up to 400 kg/m²;

- eave height up to 10 m.

Customer reviews

No reviews were found for Sperotto - Cow Sheds. Be the first to review!