Flat-Bottomed Silos with Walls

From Silos

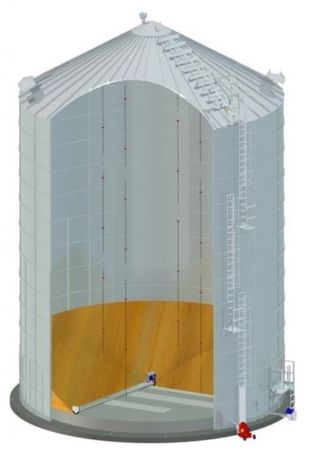

Thick walls made of flat sheet metal ensure a very stable, durable and deformation-resistant structure. The flat sheet minimizes the deposition of dust and grain on the internal walls of the silo. Specially sealed joints of the side walls and screw elements ensure the tightness of the silo shell, so that water does not get inside. All screws and washers are galvanized (class 8.8 and 10.9) and are additionally covered with a special anti-corrosion coating. Inside the flat-bottom silos there is an active grain ventilation system. The turbovent extraction head on the roof, ventilators, blowers and ventilation channels mean that once the grain has been poured, it does not need to be moved from silo to silo. The selection system and the self-cleaning effect achieved by using a flat sheet make the silo easy to keep clean. Flat-bottomed silos are made of high-quality Swedish steel. The silo structure is covered with corrosion-resistant sheet metal.

-

Most popular related searches

Product Details

Flat-bottomed silos with walls made of SPA flat sheet metal

In the silo - the use of a turbovent exhaust head on the roof of the silo prevents the accumulation of moistureFlat-bottomed silos with walls made of flat sheet metal SPA

Flat-bottomed silos are intended for long-term storage. They can be used as grain silos, rapeseed silos, corn silos and silos for legumes and other materials loose.

HIGH QUALITY SHEET METAL

- protects the product against corrosion

FLAT SHEET METAL

- provides a very stable, durable and deformation-resistant structure, which is reflected in the thickness of the silo walls.

EASY TO KEEP CLEAN

- after emptying it.

MINIMIZED DEPOSITION

- grains on the inner walls of the silo.

TIGHT CONSTRUCTION

- protects against water ingress into the interior of the silo, specially sealed connections of side walls and screw elements ensure tightness of the silo shell.

ACTIVE VENTILATION SYSTEM

- in the silo - the use of a turbovent exhaust head on the silo roof prevents the accumulation of moisture

Why Is It Worth It?

Flat-bottomed silos are intended for long-term storage. They can be used as silos for grain, rapeseed silos, corn silos and silos for legumes and other bulk materials.

- Active ventilation system

- Swedish steel of the highest quality

- High corrosion resistance

- Solid roof

- Tight and solid construction

Customer reviews

No reviews were found for Flat-Bottomed Silos with Walls. Be the first to review!