Agricultural Industry Equipment

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Specially formulated to keep farm retention and irrigation ponds clean and clear. The specialized bacteria in PBL and HCSC have been chosen to naturally eliminate organic waste and sludge while improving water quality and reducing nitrate compounds and phosphates. These undesirable compounds can lead to unwanted algae and weed growth. MICROBE-LIFT® bacterial products are safe for people, ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Reef Industries has always devoted significant time and energy to developing and keeping the highest quality products for our customers, and our NPT/Hose Adapters are no exception to this rule. This 3/4" nylon fitting is for use when trying to connect an NPT fitting to a garden hose, and is normally used with a bulkhead ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Feed Additive Blend – Microbial Supplement for Poultry – 5 Billion CFU/g. ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Your livestock is valuable, so protect them from the elements with Griffolyn livestock curtains, made from high quality and high-performance polyethylene laminates that are internally scrim reinforced to provide high performance and long-lasting ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Ponds, tanks, raceways, and other aquaculture facilities often require lining materials. Reef Industries Inc. manufactures Permalon®, a uniquely engineered alloyed polyethylene cross-laminate. This patented product offers excellent physical properties, outstanding service life, and is non-toxic to fish. High strength and high-performance Permalon® materials are available in stock ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

O.range Consists of a range of four products called (Start, Wean, Growth & Nurse) which have One common diet profile with four specific formulations covering the optimal growth & health of young post lavae, learning from the industry experience to follow larvae and fry development needs during all hatchery production phases. O.range provides the perfect solution as the entire range has ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Composed of a drop tube with plastic shutter and a stainless steel feed-type selector switch. They can delivery from 2 to 5 different types of feed, with only one ...

-

PremiumManufactured by Aralabbased in PORTUGAL

From traditional white fluorescent lights to the most advanced configurable spectrum leds, aralab has the most advanced solutions for plant research and growth. ...

-

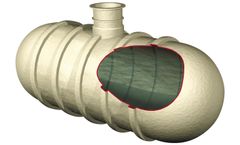

PremiumManufactured by Kingspan Klargesterbased in IRELAND

Our below-ground Cesspools and Silage Tanks provide a reliable solution for the collection and retention of sewage, surface water, veterinary/animal waste, firefighting reservoirs and rainwater harvesting ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Quantum-HSC is a plant and soil inoculant that restores and enhances the foundational levels of soil biology (also known as the soil food web). This product incorporates heterotrophic bacteria into a diverse microbial formulation that provides unprecedented plant enhancement at foliar, root and rhizosphere. The addition of humate material to the formulation provides a readily usable carbon ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Formulated specifically for the removal of organic bottom or surface solids that are slow to degrade. Provides rapid, natural sludge and muck removal and works 80% faster than competitive products. Binds phosphate and helps with the liquification and nutrient enhancement of manure. Organic and microbial based. MICROBE-LIFT/ SA-O is designed to be used with ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Fast-Acting AGRICULTURAL ODOR ELIMINATOR specially Formulated for SOLID MANURE PILES in Yards and Feed Lots. MICROBE-LIFT/AOE-D Odor Eliminator is effective against a variety of nitrogen-and-sulfur-containing compounds, classically associated with waste-odor problems including amines, ammonia, mercaptans, and hydrogen sulfide. Works within 20 minutes, based on ...

-

PremiumManufactured by Aralabbased in PORTUGAL

State-of-the-art controlled environment chambers for Leafy Greens or Cannabis production using hydroponic irrigation and LED lighting. Our FitoClima Production Rooms provide precise control over temperature, humidity, light, CO2 levels, air circulation, fertigation, filtration, and disinfection. This innovative agricultural paradigm enables the production of fresh vegetables and medical plants ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

The SunScan Canopy Analysis System uses field measurements of Photosynthetically Active Radiation (PAR) in crop canopies to provide valuable information about Leaf Area Index (LAI) and biomass production. The SunScan canopy analyser is optimised for low regular canopies such as most agricultural crops. The 1m probe enables rapid spatial averaging of large areas and PAR mapping for non-uniform ...

-

PremiumManufactured by HRS Heat Exchangers Ltd.based in UNITED KINGDOM

Aseptic filling ensures products remain safe, fresh and retain quality for up to twelve months, thus maintaining their taste, colour, texture and the essential nutritional values. The HRS AF Series is a range of single and dual head aseptic fillers for use with ‘bag-in-box’ and ‘bag-in-drum’ type sterile packaging ...

-

PremiumManufactured by Delux Manufacturing Companybased in USA

Grain Dryer: Low Profile Design – 16’ + Legs. Single and Three Phase Models Available. Capacities Up To 1,400 BPH. Energy Efficient. Vacuum Cooled Design. Very Clean & Quiet. StayKleen Designed System in Plenum and Cooling Sections. Large Plenum Access Door. Standard Service Platform. ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you