- Home

- Companies

- Zhongshan Ewater Aquaculture Equipment ...

- Applications

- Intensive Tilapia fish farming ...

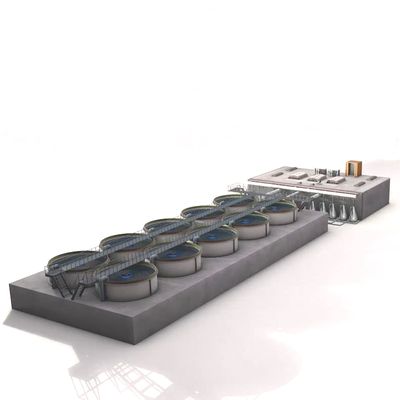

Intensive Tilapia fish farming Recirculating Aquaculture Systems ras equipment - Agriculture - Aquaculture

RAS offers the advantage that temperature and other variables can be controlled, in order to maximise growth and maintain fish health. Recirculating systems also require much less incoming water, some newer plants require only approx. 1 – 5%, compared to

All essential equipment for tilapia fish farming hatchery system

The Recirculating Aquaculture Systems principle is based on the re-use of water. Recirculating Aquaculture Systems rely on different water treatment techniques to maintain an optimal water quality for the fish. The interest in recirculation farms is still growing and the filtration techniques are constantly evolving.

The urge for RAS started when the demand for intensive aquaculture increased. RAS makes it possible to produce large amounts of fish with a small footprint and a minimal amount of water. Currently the water use of recirculating systems can be as low as 0.3 m3 water / kg feed resulting in an hourly degree of recirculation of >99%.

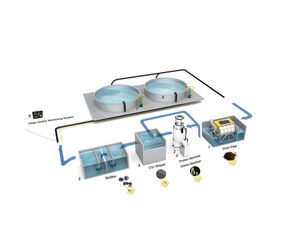

To be able to maintain proper water quality a cascade of water treatment steps need to be installed in the farm. System set-ups can change per species, but the main treatment processes consist of mechanical filtration, biological filtration, CO2 removal, O2 addition, recirculating pumps and some form of disinfection. In addition to this it is important to be able to control at least the pH and temperature of the water. Fish can be grown faster and with a better food conversion ratio compared to extensive fish farming because of this high amount of control over the water parameters. Furthermore, farming in a closed system on-land results in increased bio-security and a higher flexibility in site selection.

The Recirculating Aquaculture Systems principle is based on the re-use of water. Recirculating Aquaculture Systems rely on different water treatment techniques to maintain an optimal water quality for the fish. The interest in recirculation farms is still growing and the filtration techniques are constantly evolving.

The urge for RAS started when the demand for intensive aquaculture increased. RAS makes it possible to produce large amounts of fish with a small footprint and a minimal amount of water. Currently the water use of recirculating systems can be as low as 0.3 m3 water / kg feed resulting in an hourly degree of recirculation of >99%.

To be able to maintain proper water quality a cascade of water treatment steps need to be installed in the farm. System set-ups can change per species, but the main treatment processes consist of mechanical filtration, biological filtration, CO2 removal, O2 addition, recirculating pumps and some form of disinfection. In addition to this it is important to be able to control at least the pH and temperature of the water. Fish can be grown faster and with a better food conversion ratio compared to extensive fish farming because of this high amount of control over the water parameters. Furthermore, farming in a closed system on-land results in increased bio-security and a higher flexibility in site selection.

Protein skimmer or foam fractionators are used for removal of fine solids and dissolved protein from the water. Protein skimmers remove dissolved particles from a waste water flow by adsorption of the particle at the gas-liquid surface. Water molecules that border an air surface tend to align themselves. Foam fractionators are especially suitable for removal of particles smaller than 30 micron and particles that have an electric charge. The higher the salinity of the water the more effective the skimmers are, because of the formation of finer air bubbles, due to the increased surface tension.