- Home

- Companies

- Beston Group Co., Ltd.

- Articles

- An In-Depth Look at the Advantages of ...

An In-Depth Look at the Advantages of Automatic Egg Tray Making Machine

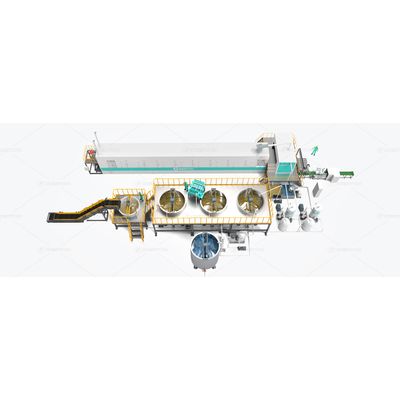

The shift towards automation in manufacturing processes has revolutionized industries worldwide, including packaging. One of the most notable advancements in the packaging sector is the introduction of the automatic egg tray making machine. This technology not only enhances efficiency but also provides significant economic and environmental benefits. By automating the production of egg trays, manufacturers can achieve a higher level of precision, consistency, and scalability, making the automatic egg tray making machine a valuable investment for businesses in need of large-scale, high-quality packaging solutions.

Increased Production Efficiency

One of the most significant advantages of an automatic egg tray making machine is its ability to increase production efficiency. Unlike manual production methods, where human intervention is required at each stage of the process, the automatic machine operates continuously with minimal oversight. The system automates critical steps such as pulp preparation, tray molding, drying, and even packaging. This level of automation reduces labor costs, minimizes human error, and accelerates the production cycle.

The machine’s high-speed operation ensures that large quantities of egg trays are produced in a short time frame. This is particularly beneficial for businesses with high demand or those seeking to meet tight production schedules. Furthermore, automation allows for precise control over the production parameters, ensuring that each tray meets the desired specifications without variations in quality.

Consistent Product Quality

A paper egg tray making machine is designed to produce trays with consistent quality. The precision of the machine ensures that each tray is molded uniformly, with minimal deviation in shape, thickness, and overall structure. This consistency is crucial in industries where packaging integrity is paramount, such as food and electronics.

The machine’s automation eliminates the risks associated with human error, such as uneven pulp distribution or inconsistent molding pressure, which can result in weak or malformed trays. As a result, manufacturers can be assured that their products will meet the highest standards of quality, ensuring better protection for fragile items like eggs or electronic components.

Cost-Effectiveness and Scalability

The initial investment in an automatic egg tray making machine may seem significant, but the long-term cost benefits are substantial. Automation reduces the need for manual labor, lowering operational costs over time. The ability to produce large volumes of trays at a faster rate means that businesses can meet market demand without the need for constant workforce expansion. This cost efficiency is especially important in industries where price sensitivity and competitive pricing are critical factors.

Additionally, the scalability of the automatic egg tray making machine makes it suitable for businesses of all sizes. Whether a company is producing small quantities of trays for local markets or scaling up for large-scale distribution, the machine can be adjusted to meet varying production needs. This flexibility enables businesses to grow without the need for significant reinvestment in equipment or infrastructure.

Environmental Benefits

An often overlooked advantage of the automatic egg tray making machine is its positive impact on the environment. The machine operates with minimal waste, as it utilizes recycled paper pulp, which is an eco-friendly raw material. By repurposing paper waste, the machine helps reduce landfill volumes and lowers the demand for virgin materials.

Furthermore, the production process of the automatic machine is designed to optimize energy consumption. The automation system ensures that energy is used efficiently, reducing overall power consumption compared to manual or semi-automated systems. Some models of the automatic egg tray making machine also incorporate advanced drying technologies, which further enhance energy efficiency and reduce operational costs.

Minimal Maintenance and Durability

Another key advantage of the automatic egg tray making machine is its low maintenance requirement. Modern machines are engineered with durable components designed to withstand continuous operation. This durability reduces downtime and maintenance costs, which is essential for businesses that rely on consistent production output.

The machine’s robust design ensures long-term reliability, even under high production volumes. With proper maintenance, an automatic egg tray making machine can operate effectively for years, providing a stable return on investment.

Conclusion

The automatic egg tray making machine offers a host of advantages, from increased production efficiency and cost-effectiveness to consistent product quality and environmental benefits. Its ability to automate the egg tray production process, while maintaining high standards of quality, makes it an indispensable tool for businesses in the packaging sector. As sustainability becomes an increasingly important consideration for manufacturers, the automatic egg tray making machine stands out as a versatile, reliable, and eco-friendly solution to modern packaging challenges.