- Home

- Companies

- Beston Group Co., Ltd.

- Articles

- How to Improve Efficiency in Production ...

How to Improve Efficiency in Production Using an Egg Tray Maker

Maximizing production efficiency is a crucial aspect of modern manufacturing. In the context of egg tray production, achieving high efficiency not only boosts throughput but also helps reduce costs and environmental impact. An egg tray maker is central to this process, as it automates the production of egg cartons, a task that traditionally required significant manual labor. By leveraging the capabilities of an egg tray maker, manufacturers can streamline operations and improve overall productivity.

1. Optimize Material Use

One of the most effective ways to improve efficiency is to optimize the use of materials. The egg tray maker relies on paper pulp, typically sourced from recycled paper, which is mixed with water to create a slurry. The pulp’s consistency must be carefully controlled for optimal results. If the pulp is too thick, it can clog the system, leading to longer production times. Conversely, too thin a mixture can weaken the trays, reducing their quality.

By investing in a high-quality egg tray maker that includes automated pulp preparation systems, manufacturers can ensure that the pulp consistency is maintained within the ideal range. This reduces material waste and ensures that the maximum number of trays are produced from each batch of raw materials, directly improving production efficiency.

2. Leverage Automation

Automation plays a pivotal role in increasing the efficiency of egg tray production. A modern paper moulding machine is typically equipped with fully automated systems that handle everything from pulp molding to drying. These systems reduce the need for manual labor, thereby cutting down on human error and improving consistency.

Automation ensures that production is continuous, with minimal downtime for adjustments or repairs. For instance, automated conveyors, mold cleaning systems, and material handling systems all work together to keep production lines running smoothly. This reduces delays caused by manual intervention and increases the overall throughput of the system.

Furthermore, many egg tray makers now come with real-time monitoring systems that allow operators to track production data, such as cycle times, material usage, and machine performance. This data can be used to identify inefficiencies and make adjustments on the fly, ensuring that production stays on track and runs at optimal efficiency.

3. Improve Drying Systems

The drying process is one of the most time-consuming steps in egg tray production. Traditionally, drying could take up a significant portion of production time, especially when done manually or with inefficient systems. By upgrading to an egg tray maker with advanced drying technologies, manufacturers can drastically reduce drying times.

Modern machines often incorporate infrared dryers or conveyor belt drying systems that utilize heat exchange or forced air to accelerate the drying process. These systems ensure that egg trays are dried quickly and uniformly, which reduces the overall production time and increases throughput. Additionally, efficient drying systems help minimize energy consumption, contributing to more sustainable and cost-effective production.

4. Streamline Maintenance and Downtime

Even the best egg tray maker requires maintenance to operate at peak efficiency. Unscheduled downtime due to equipment failure can severely disrupt production schedules. To minimize this risk, it is essential to establish a proactive maintenance plan. Many modern egg tray makers are designed with self-diagnostic capabilities, allowing operators to detect potential issues before they lead to system failure.

Regular maintenance of key components such as the molding system, drying equipment, and conveyors is crucial. By scheduling routine checks and using high-quality parts, manufacturers can extend the lifespan of their machines and reduce the likelihood of costly repairs. Moreover, implementing predictive maintenance practices can ensure that parts are replaced before they wear out, preventing unscheduled halts in production.

5. Optimize Production Line Layout

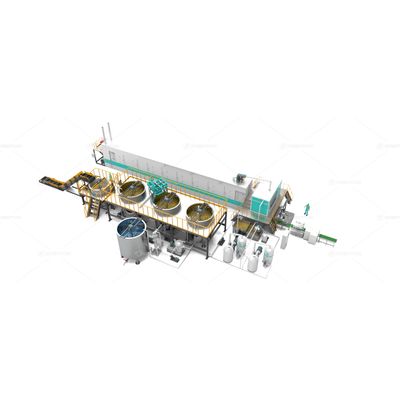

The layout of the production line is another critical factor in improving efficiency. The flow of materials and finished products should be designed to minimize bottlenecks and optimize worker movement. An egg tray maker, when integrated with an efficient production line, should be strategically placed to reduce the time spent moving materials between stages.

For instance, placing the pulp preparation system, molding section, and drying zone in close proximity reduces handling time and transportation costs. Similarly, automated systems should be used to transport finished trays to the packaging area, further reducing human involvement and potential for delays.

6. Use of Quality Control and Feedback Loops

Incorporating quality control measures within the production line can also enhance efficiency. An egg tray maker that includes built-in quality monitoring systems can detect defects in real-time, such as improperly molded trays or excessive moisture content. This allows operators to address issues immediately rather than at the end of the production cycle, saving time and resources.

Implementing a feedback loop into the production process ensures continuous improvement. By monitoring machine performance and quality output, manufacturers can quickly adjust parameters to optimize production. For example, adjusting the pulp consistency or mold pressure based on the quality of the trays being produced helps to maintain a high standard while maximizing production speed.

Conclusion

Improving efficiency in egg tray production relies on a combination of advanced technology, optimized workflows, and effective maintenance practices. The egg tray maker, with its automation, material handling systems, and precision molding capabilities, is at the core of this effort. By focusing on optimizing material use, automating processes, enhancing drying systems, maintaining equipment, and ensuring a streamlined production layout, manufacturers can significantly boost efficiency. As a result, production becomes faster, more cost-effective, and capable of meeting increasing demand for high-quality, sustainable packaging solutions.