- Home

- Companies

- Absolute Ozone®

- Articles

- Ozone for Grain Storage

Ozone for Grain Storage

The loss of grain in storage relating to or resulting from living things such as insects, pests, rodents, and fungi and form physical rather than biological such as temperature or moisture lead to global losses that exceed 80 million metric tons in grain storage. Most of the time, Aluminium Phosphide is used for fumigation, though it can be dangerous. Also, insects and pests have developed resistance to phosphine. Other fumigants such as carbonyl sulfide, ethyl formate, hydrogen cyanide, methyl iodide, and propylene oxide have high costs compared to phosphine (Singh and Sharma 2015). On the other hand, several studies have demonstrated that ozone is effective in treating the grain with the advantage of not affecting its quality when dose and exposure time is properly controlled.

Ozone has been successfully used as the best alternative fumigant against stored product insects. Various works on the usage of ozone as a greener alternative for commercial fumigants have been studied.

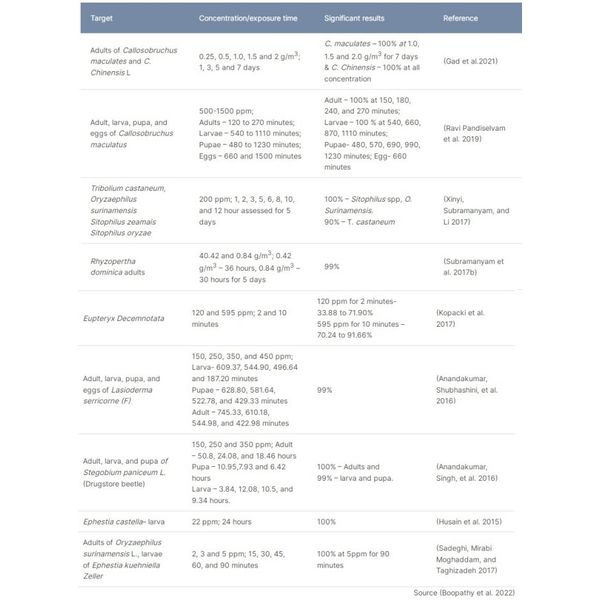

The effect of ozone fumigation in terms of concentration and exposure time on selected food grains and insects is summarized in the next table

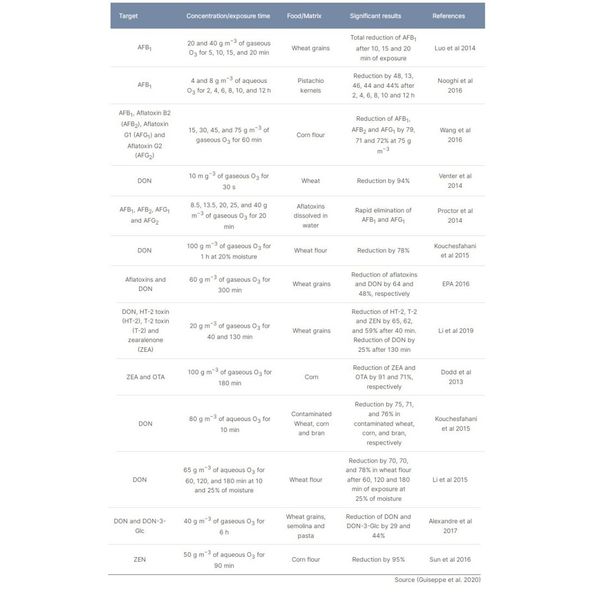

Wheat grain can be treated with ozone to reduce levels of fungi and mycotoxin. Guiseppe et al. 2020 summarize studies showing ozonation is an effective method for removing mycotoxins and detoxifying contaminated agricultural products. They are approximately 400 mycotoxins, of which 30 are considered dangerous to humans and animals. Ozone was able to degrade more dangerous mycotoxins in many food/feed portions and several operational conditions.

Applied ozone has given promising results for important issues in the food industry, such as mycotoxin contamination and pesticide residues. A particular benefit of O3 is its ability to inhibit fungal growth, sporulation, and germination without losing nutrients or sensory qualities. O3 concentration, contact time, and other treatment conditions should be defined for foods and feed to ensure their effectiveness and safety in processing. Since every O3 application is unique, the concentrations and contact times shown before are only guidelines. In the published studies, there were discrepancies in the effect of O3 on insects, microorganisms, and mycotoxins. These discrepancies might be caused by the highly reactive nature and short half-life time of O3 that limit O3 penetrating into grain mass and grain kernels. Therefore, the most failures by various investigators might be their inability to distinguish between the concentration of applied O3 and O3 reacting with microorganisms, mycotoxins, and insects.