- Home

- Companies

- Geoflow, Inc. - A Subsidiary of Anua ...

- Articles

- Reuse of Dairy Lagoon Wastewater ...

Reuse of Dairy Lagoon Wastewater Through SDI in Forage Crops

Abstract

California has become the leading dairy products producing state in the USA. This has resulted in farms commonly milking several thousand cows per day. The care and feeding of the animals has produced large waste streams commonly collected and stored in lagoons. Environmentally safe handling and reuse of the lagooned wastewater is the objective of this study. A system of Subsurface Drip Irrigation (SDI) is described and the first year operation and results summarized. The system features a tube with a bactericide lining with an internal plug resistant emitter protected from root intrusion by an impregnated herbicide. A PLC with special software and a wireless phone connection provides for off-site control. The system operated satisfactorily during the first season producing commercially acceptable yields. The crop absorbed high levels of nitrogen from the wastewater. Special care is required in the feeding of the hay to animals. The concept shows potential as a means of recycling animal waste in an economical and environmentally sound manner

Introduction

There is a growing world-wide concern about animal waste discharges affecting groundwater quality. The use of dairy wastewater (WW) for irrigation is subject to concern because of the possible nitrate contamination of domestic water supplies and health hazards from the pathogens in WW.

WW usually contains three major forms of N: (1) Ammonium; (2) Organic N; and (3) Nitrate/nitrite. Ammonium (NH4+) represents the principal form of N in WW (5-40 mg N/L), but in most soil containing significant clay, NH4+ can be either fixed by clay particles or temporary adsorbed by negatively-charged clay and organic colloids. Organic N is readily converted to NH4+ by the mineralization transformation process resulting from aerobic and anaerobic bacteria activity. A two step nitrification process transforms NH4+ to nitrite-N and then nitrite-N to nitrate-N, involving respectively Nitrosomonas and Nitrobacter bacteria. Although these bacteria are present in most soils, their population may be quite low in subsoils an dry sandy soils and their activity may be restricted if the soil temperatures are low (Broadbent and Reisenauer, 1990).

The staff of the Water Management Research Laboratory (USDA-ARS-Fresno) developed a highly efficient irrigation and management method which minimized and sometimes even eliminated the downward movement of soluble nitrate-N below the root zone of field crops. This high frequency subsurface drip irrigation (SDI) system should be ideal for applying WW with minimal potential leaching of nitrate-N, because the nitrification process will be minimized and most NH4+ molecules will be either fixed or adsorbed by the soil or taken up by the deep roots.

Three physical characteristics, unique to SDI, contribute to its advantages and to minimizing nitrate-N leaching: (1) Reduced evaporation; (2) Larger wetted soil volume and surface area than surface drip irrigation; and (3) Deeper rooting.

A major factor in the environmental problems associate with animal effluent disposal arises from run-off caused by rain events and poorly managed irrigation. Pathogens, nitrates and phosphates in the run-off cause serious problems in the surface waters. In addition to the controlled movement of NO3-N to the ground water, the fact that the WW is not applied to the surface and does not come to the soil surface adds a major safety dimension to effectively eliminating the risk of pollution due to run-off.

History

Velledis et. al. (Velledis, 1997) has shown that between 400 and 600 kg N per ha per annum can be applied through a center pivot system spraying dairy effluent on a rotation of fodder crops

-

The development of technology which prevents the deterioration of the subsurface drip system due to root intrusion (Ruskin, 1997) makes it practical to install the SDI system in permanent crops like alfalfa which have an expected life of ten years, or more.

-

When the active root system of alfalfa is 0.5 m deep, the nitrogen fixation process may be impaired and the frequent injection of N is needed to produce good quality alfalfa and high yields. USDA-ARS-WMRL research results with SDI for alfalfa have shown that this method is indeed feasible, conservative, and sustainable.

The combination of these three factors gives good reason to expect that SDI and alfalfa may be a very suitable combination to mitigate the dairy effluent problems.

The Center for Irrigation Technology at California State University, Fresno has been investigating solutions for the safe disposal and reuse of wastewater generated from the university dairy lagoon to grow alfalfa. The primary objective of the studies to date has been to demonstrate an economical yet technically practical and commercially feasible method. This study has used WW from a conventional dairy lagoon followed by a sand media filtration to produce effluent of sufficient quality to be used in the SDI system. The ROOTGUARD® technology is used to provide root intrusion protection. Because of the relatively low N concentration, this disposal method could be used with a deep rooted crop such as alfalfa, using a SDI system installed at 0.60 m or deeper. The purpose of this research is to investigate the feasibility of growing alfalfa with the dairy effluent using SDI, and to measure the nitrate movement below the root zone. The quality of alfalfa will be recorded. Extra nitrogen or other fertilizers will not be added even if they are needed to optimize yield or quality.

Project Design and Operation

The soil is a fine sandy loam. Proper cultivation is required to meet the agricultural objectives of the project. In this case the deep rooting characteristics of the crop (to 1.2 m) and the deep placement of the drip line (.6 m) required deep ripping of the site (also to 1.2 m). This was followed up by disking, pre-plant fertilization, and chemical herbicide applications. The plot was planted with Germains WL 612 alfalfa at a rate of 34 kg/ha. In California, alfalfa is best planted in September for good germination. The plot was irrigated by a portable sprinkler system until it was well established. It seems likely that with many crops irrigated by SDI, plantings will have to be carefully synchronized to rainfall patterns or sprinkler systems used to get good stands. Getting good stands can also be a chronic problem with flood irrigated alfalfa fields. As the irrigation demand developed in the spring of 1999 the SDI system was used to meet crop needs.

Since this is an experiment to study environmental impact and equipment performance and not yield, a single unreplicated plot 8.5 m wide by 185 m long was installed. This accommodated the installation of seven, 185 m long drip-lines spaced 1.2 m and buried 0.6 m under each row. The 185 m length corresponds to lengths commonly found in commercial fields and therefore allows for full scale hydraulic observations. The depth of burial anticipates governmental regulations prohibiting the presence of free wastewater on the field surface. At this depth, the crop can be fully irrigated without the necessity of wetting the soil surface.

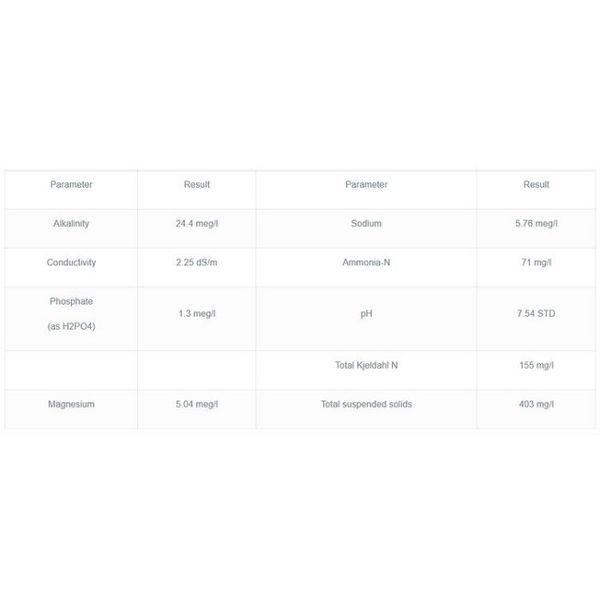

This dairy lagoon wastewater is heavily laden with both dissolved and suspended materials, A representative laboratory analysis is given in table 1 for a sample taken after the system filtration equipment.

The tube has an internal lining containing a bactericide to inhibit the growth of slime on the wall. To be suitable for placement by direct shanking in place, the turbulent flow emitters are molded into the ½ in. nominal drip-line (ID 14 mm x OD 16 mm) at a spacing of 610 mm. The emitter is protected by a molded in compound Treflan® that is designed to stop root intrusion. Also by actual test, the emitter has a demonstrated ability to resist plugging by particulate matter. The drip-line is manufactured by Geoflow, Inc. San Francisco, California USA. PVC pipe manifolds are connected at both ends of the system. The downstream manifold is connected to an valve that flows back to the reservoir. Because the suspended solids, even after filtration, is very high, at the end of each daily cycle, this valve is opened to flush the system back to the reservoir.

A barge mounted pump and inlet screening arrangement floats on the lagoon surface and draws water from 0.9 m below the water surface. This avoids both floating debris and settled solids. Conventional sand media filters (2,300 mm diameter tanks) and a 200 mesh screen filter are being used to protect the system from plugging. Instrumentation includes standard pressure gauges, an electronic paddle wheel flow rate sensor, and a maximum/minimum electronic ambient air temperature sensor. A commercially available PLC controls the system with communication access through a wireless phone. Special software was developed to accommodate unique aspects of the application. A special computer graphics interface has been developed to permit simple operation by comparatively untrained personnel.

As originally visualized the system was to be automatically controlled with a manual over ride. The automatic control includes a daily calculation of crop consumptive using the air temperature sensor readings and the Hargreaves Formula. This results in a required daily dose volume calculation that is controlled by the flow meter. System efficiency estimates will be adjusted to insure adequate irrigation. Eventually a soil moisture meter will be added to abort the scheduled daily dose if the root zone becomes saturated. To date as of February 1, 2000 this system has not been tested.

The manual system of control operates similarly to a standard irrigation controller. A weekly calculation is made to establish run times. An automatic weather station (CIMIS) is accessed to acquire current reference evapotranspiration. Using appropriate crop coefficients, crop evapotranspiration is calculated and converted to dose time. This and scheduled run days is communicated to the infield PLC using the wireless phone.

Results

The original attempt to filter the wastewater involved the use of a static 200 mesh screen filter with an automatic backflush. Because of the fibrous nature of the solids this concept did not work. The fibers could not be flushed clean of the screen surface. This screen filter was replaced with a sand media filter using #20 feldspar media underlain by ¾ in. (19 mm) crushed gravel. The loading rate is 450 l/min./m 2 (11.0 gpm/ft. 2 ). The system is set to backflush every 15 minutes of operation. Backflush valving is arranged so that the system shuts down while the tanks are backflushed sequentially. It is backed up by a downstream 200 mesh screen filter for safety. Routine operation began the second week of June, 1999. Scheduled and actual applications are as documented in Table 2.