- Home

- Companies

- Beston Group Co., Ltd.

- Articles

- Safety and Quality Standards for Egg ...

Safety and Quality Standards for Egg Tray Machine Products

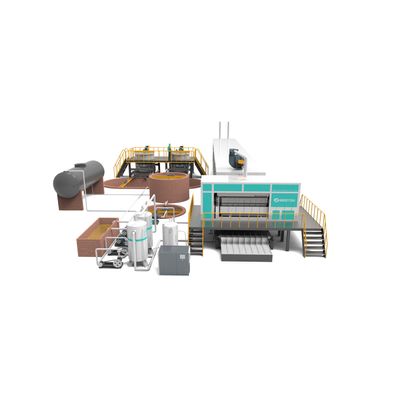

The egg tray machine plays a vital role in the manufacturing of molded pulp products, which are used in various industries for packaging, particularly in the food sector. As demand for environmentally friendly and cost-effective packaging solutions grows, ensuring the safety and quality of products produced by these machines is critical. Compliance with international safety standards and maintaining consistent quality are essential for manufacturers aiming to meet both consumer expectations and regulatory requirements.

Adherence to Safety Regulations

Ensuring the safety of both operators and consumers is paramount in the production of egg trays. The design and operation of an egg tray machine must comply with stringent safety standards. These standards are set by regulatory bodies to minimize risks associated with machine operation, such as mechanical failures, electrical hazards, or potential exposure to harmful chemicals used in the pulp molding process.

To meet safety standards, manufacturers must implement several key features in the machine’s design:

Emergency Stop Systems: An egg tray machine should be equipped with easily accessible emergency stop buttons. This allows operators to halt operations immediately in the event of a malfunction or safety issue.

Guardrails and Safety Shields: Mechanical parts that pose potential risks, such as rotating blades or conveyors, must be properly shielded to prevent accidental contact.

Electrical and Fire Safety: Machines should have reliable grounding systems and overcurrent protection to safeguard against electrical faults. Additionally, the equipment must be designed to prevent the accumulation of dust or flammable materials, reducing the risk of fire.

These safety features not only protect workers during the production process but also ensure that the final product is safe for use, especially when intended for food-related applications.

Consistent Product Quality

In addition to safety, maintaining high-quality standards in the production of molded pulp products is essential. The pulp molding machine, which serves as the heart of the egg tray production process, must be calibrated to deliver consistent results. Variations in the pulp mixture, molding temperature, or drying time can lead to defects, such as weak or irregular trays, which can compromise their effectiveness as packaging materials.

Several factors contribute to ensuring product quality:

Pulp Quality: The raw material used in the paper pulp process plays a significant role in the quality of the end product. High-quality recycled paper should be selected to ensure a consistent pulp mixture. The proportion of water, fibers, and other additives must be carefully controlled to achieve the desired strength and texture of the egg trays.

Mold Precision: The egg tray machine uses molds to shape the pulp into trays. These molds must be precise and well-maintained to ensure uniformity in size and shape. Molds that are worn out or damaged can lead to defects in the trays, affecting both the product's functionality and appearance.

Drying Process: The drying phase of egg tray production is crucial for achieving the desired strength and durability. Insufficient drying can result in trays that are too soft or prone to breaking, while over-drying can lead to brittleness. The drying system must be efficient, ensuring that the trays are fully dried without compromising their structural integrity.

Compliance with Industry Standards

Manufacturers of egg tray machines must adhere to various industry standards, both local and international, to guarantee the quality and safety of their products. Compliance with standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management is critical for ensuring consistency in production and minimizing the environmental impact of manufacturing operations.

Additionally, many regions have specific regulations regarding food packaging, particularly for items in direct contact with consumables. These regulations require that products made using pulp molding machinery, such as egg trays, be free of harmful substances, ensuring that they are safe for use in food-related applications.

Conclusion

The egg tray machine, when operated in accordance with safety protocols and quality standards, provides a reliable solution for producing high-quality, eco-friendly packaging. By ensuring strict adherence to safety regulations and implementing quality control measures throughout the production process, manufacturers can meet the increasing demand for sustainable packaging while safeguarding both their workforce and consumers. The role of the pulp molding machine in this process cannot be overstated, as it is the cornerstone of producing durable, uniform, and safe egg trays that meet the highest industry standards.