Separators for grain cleaning. What are they? How they work. And what are they for?

Grain cleaner or as it is also called - sorter, grain cleaner, trier.

- is a specially designed machine for a single task - cleaning grain and various crops.

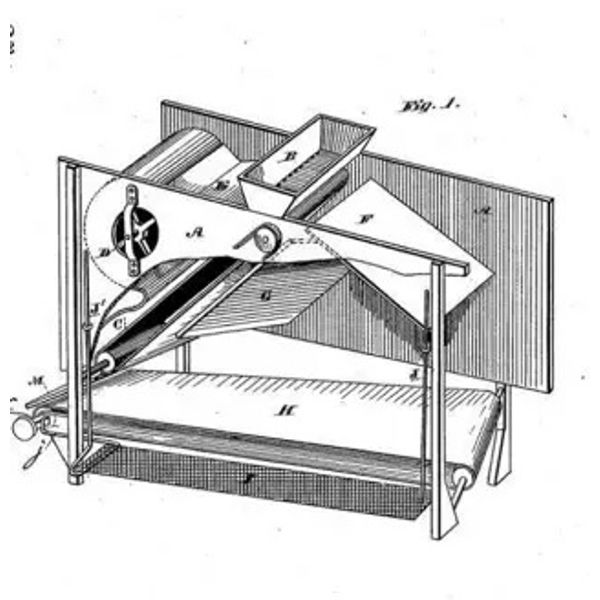

As far back as 1313, ancient China pioneered the use of a rotating fan that created an airflow to separate chaff from grain, but this was still a long way from the separator in the form we are used to today The first grain cleaner with similarities to modern grain cleaners was developed in the USA in 1883 by Mr Wilcox.

It already had the basic principles of a modern sorter - such as a hopper where the grain enters; a sieve that would clean the product by means of its size, and also a fan, albeit a rudimentary one.

If there is one moment in history when annual innovations for grain separators began, it is this. Since then, more than 2,700 patents have been issued, and that`s just the ones officially registered in Europe and the USA, which relate to the machines themselves.

Modern grain separators - are indispensable equipment in the processing of grain crops, as well as in the production of cereals, flour and other nutritious products. This equipment is used for the primary and subsequent stages of grain processing. This unit separates impurities, small foreign bodies from the entire mass of grain in order to qualitatively clean the raw material and its supply to the processing line.

Let`s look at what this machine is for by way of example.

After the harvest, farmers will have to do a lot of work to ensure that the grains are ready to go to consumers: to processing plants, food processing plants and supermarkets.

In the beginning, the grain collected from the field arrives at the receiving and processing plants with impurities: grain from another crop, sand, soil, pebbles, weeds, straw and ear residues, chaff. According to different statistics such impurities are from 10 to 40%. For long-term storage and excellent quality of finished products, all impurities must be removed. If not in time or poorly cleaned grain crops, rather quickly their humidity will increase, the process of self-heating will begin, mould will appear, and accordingly deteriorate sowing and marketable qualities of products. There is even a risk of spoilage of the entire harvest.

In summary, we have two reasons for the importance of the separator as an invention critical and essential to the present day:

- The price of products is falling, which is bad from an economic and business point of view

- The quantity of quality grain is declining, which is bad for the humanitarian and food sector

As a conclusion: increased requirements to grain quality and the interest of many farmers to have their own production of nutritious products are the main reasons why in recent years grain separators are becoming an increasingly relevant product, as evidenced by the increasing number of these machines on advertising platforms in Europe, USA.

Grain cleaners range from the simplest devices capable only of cleaning the crop from dust and waste to more complex ones - capable of high quality complete cleaning from external impurities and sorting, calibration by size, weight, and other characteristics. For example, such high-precision devices are widely used in the confectionery industry to separate seeds of one size from the total mass of cleaned sunflower seeds, in pre-sowing preparation for seed calibration.

Most grain cleaners are divided into the following types:

- Aerodynamic separators;

- Calibrators;

- Lattice separators;

- Drum Separators;

- Trier unit;

- Gravity Separators; - Circular Cleaner;

- Densitometric table;

- Optical sorter

There are other separators, but they are already as a rule already coming from the above mentioned.

Probably the only general principle of operation of any separator is based on the fact that plant seeds can differ in weight, thickness, width, and therefore aerodynamic properties, and accordingly due to these differences the grain is cleaned on any separator.

Grain handling mainly involves separating the grain harvest into at least the following 4 fractions:

- bulky waste

- coarse selected grain intended for food production and for sowing

- feed grain

- fine debris and dust.

However, grain cleaners are otherwise distinctive. Let`s look at the features of each one, their differences, advantages, disadvantages and for whom they are designed

Perhaps the oldest type of separator. And, frankly speaking, it has not lost a bit of its relevance, despite the appearance of many new types of grain cleaners.

Principle of operation:

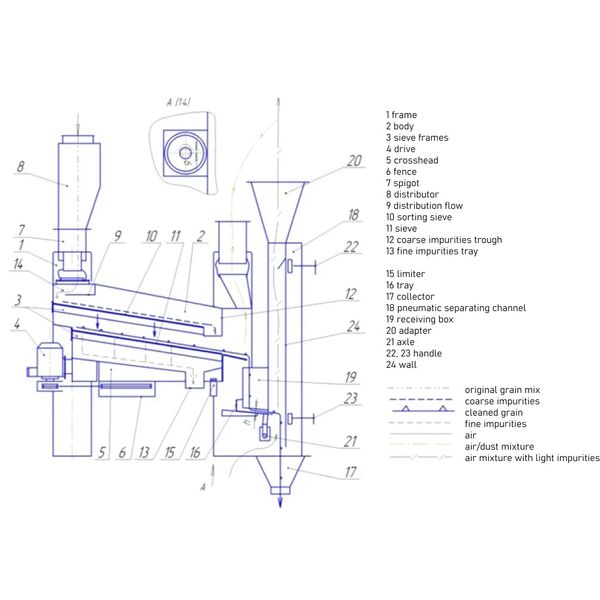

The peculiarity of sieve separators is that the separation into fractions takes place on the sieves, which in turn are attached to the frame. The high quality of cleaning is achieved by the translation-rotation movement of the sieve structures fixed at different angles.

The sieves differ in the size of the openings, each screen each sieve fulfils a different function in cleaning and screening the grain for different fractions.

Schematic diagram of the grid separator.

Standard equipment: separator, aspiration systems, sieve set. Optional accessories: fan, cyclone, stand.

Not only has this separator not lost its relevance after decades, but it remains the most common separator on the market. The reason is quite simple: new types of separators have become generally more task-specific, specific. In turn, the grid separator to this day will be able to perform well in any task, any farmer, but a quality grid separator is not cheap, so many farmers simply do not need it, and here we go to a couple of alternatives for them.

This separator is the most modern.

It is difficult to say exactly when these machines were first introduced. The aerodynamic solids separation technology was patented in 1975 by the legendary Australian grain handling company Hannaford, but there is no evidence that there was already a separator using this technology at that time. This type has only appeared on the market in the last couple of decades, and almost immediately found a buyer, which is not surprising.

The principle of operation is quite simple:

In an aerodynamic separator, the material to be cleaned is exposed to a jet of heated air. Powerful air flow blows away dust and light impurities, heavy debris falls down, and grains by weight and size (having different aerodynamics) are distributed into cells, which can be from 5 to 8, which by the way is an advantage compared to other grain cleaners. Some farmer does not need the grain to be distributed into so many fractions, and he simply combines some of them. But many do, and so it either does not hinder the farmer or is an important advantage.

Since the treatment process in an aerodynamic machine is based on the impact of a powerful air flow, there is actually no contact with rigid surfaces, as in the case of grating machines, for example. This avoids traumatising and compromising the integrity of the grain shell.

These separators are the cheapest and most affordable on the market, and you should not expect any incredible quality of grain cleaning from them. It is unlikely that these separators will be used in mustard production, even locally. But for the small to medium sized farmer, they are the way to go. Due to the fact that these separators do not need sieves, they clean most food, feed and industrial crops. Consequently, the payback period for any of the models is already in the first season of use, in contrast to the sieve and trier models.

Standard equipment: separator, control cabinet, aspiration chamber.

Benefits:

- More grain fractions

- Low price

- Quick payback

- Low power consumption

- 5. Grains are not traumatised

Disadvantages:

- Lower efficiency of grain cleaning

A calibrator is actually a simplified subspecies of a sieve separator.

The principle of operation also consists in the movement of sieves relative to each other, there is a simplified aspiration system, a fan.

The main differences are related to the fact that this type of grain cleaner is oriented towards small farmers. Its productivity is much lower, depending on the manufacturer and model (from 300 kg to 5 tonnes per hour), but the quality of grain cleaning is very high. It should be understood that the quality of its cleaning will be influenced first of all by how well the sieves are selected for a certain crop. If the sieve size is precisely matched, there will be no complaints about the quality of cleaning.

You need to know in advance which crops you are going to clean. If there are several crops and you want quality cleaning, you need to select for each crop separately. However, if it is important for you to save money, in the case of similar crops in terms of grain size, some sieves can be adapted to both crops. For example, wheat and rye are similar enough that you can clean both crops on the same sieve.

Different calibrators differ in the number of sieves. The upper sieve will clean large debris, while the two lower sieves will do the fine cleaning and separate the grain into fractions. Accordingly, a properly selected upper sieve can fulfil the function of cleaning large debris for a number of crops.

This is a kind of pre-cleaner. The two lower sieves can be selected for each crop; as a rule it takes only a few minutes to change the sieves on the calibrator.

Standard equipment: separator, sieve set, aspiration system.

Additionally, a frequency converter can be taken, which will fulfil the function of speed control and protection system.

Benefits:

- Several levels of sieves

- Cheap cost in relation to cleaning quality

- Quick change of sieves Disadvantages:

- Low performance

In fact, this type of grain cleaner is as old as the grate type, but it took a long time to gain its popularity and place in the market.

The modern drum separator (also called rotary separator) is characterised today by its impressive dimensions and very precise grain cleaning. The drum separator is designed for preliminary, primary and secondary grain cleaning.

Principle of operation:

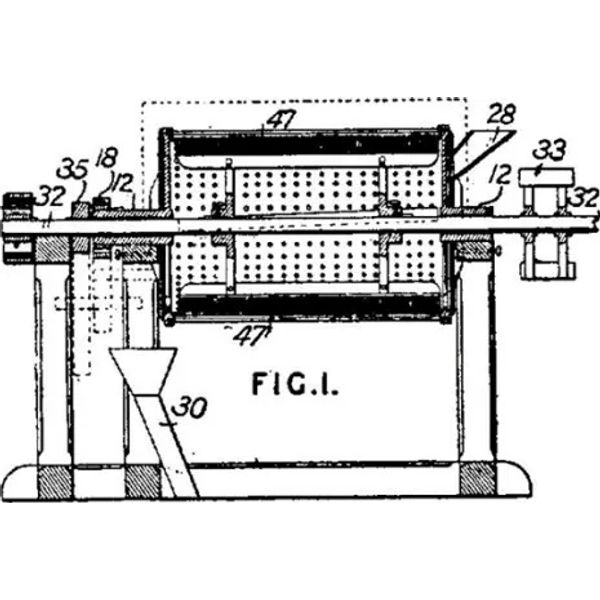

The drum cleaner consists of a drum with perforated sieves and an aspirator.

The aspirator removes all fine debris such as dust, husks and various impurities. The grain is then transferred to the sieve. The drum usually consists of several sieves with different mesh diameters. The mesh size of the first sieve is the smallest. The fine debris spills into the first sieve. On the next sieve the cells are already larger and broken grain falls through them. And the cells of the third sieve correspond to the size of the crop that is currently being cleaned on the separator.

Cleaning stages of a rotary cleaner:

1. Pre-cleaning - aspiration.

Use only aspiration to remove light impurities. The sieve drum is not used. Used when receiving grain.

2. Pre-cleaning - sorting.

Use of aspiration to remove light impurities. The drum is used to remove coarse impurities. It is used when receiving grain or when handling wet grain material.

3. Sieve cleaning - separation.

Use of aspiration to remove light impurities. Use of the first (and second) sieve for sieving, all others for pre- sorting. Used before sending the grain for processing.

4. Cleaning of the trier Use of aspiration to remove light impurities.

Use of three sieves to perform a sieving operation for fine cleaning.

5. Calibration Use of aspiration to remove light impurities.

Use of all sieves to perform the sieving operation for crop calibration.

Standard equipment: drum separator, aspirator, control panel, one set of screens and aspiration system (fan and cyclone with sluice gate)

Probably the most professional, precise machine currently available. It is difficult to do without this machine in organic farming.

The first trier was developed by the German company KALKER TRIEURFABRIK FABR in 1972. The basic operating principle and technology have remained almost unchanged since then. Structurally, it was a major breakthrough.

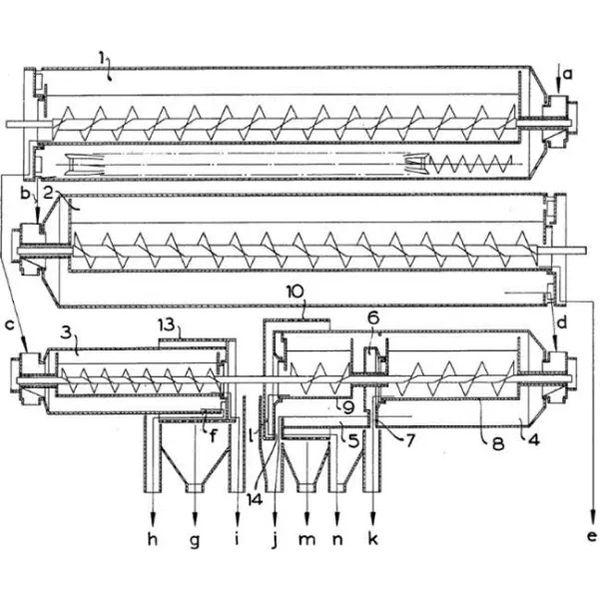

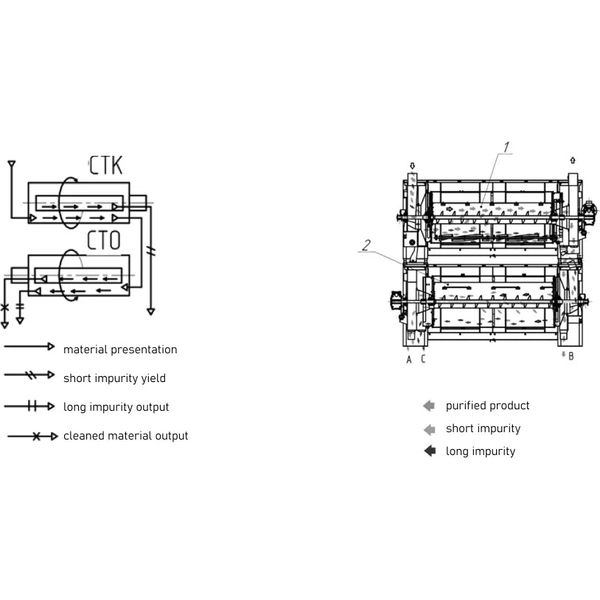

The modern trier is designed for cleaning grain and seed material of grain ear, grain legumes, cereals, oilseeds and other crops from long and short impurities (oats and kukol).

Principle of operation:

The threshing unit consists of two units located one above the other: the lower oat collector threshing unit and the upper pupae collector threshing unit, which have an autonomous drive. The upper unit is rotated 180° in relation to the lower unit. This arrangement of the unit makes it possible to work according to a sequential cleaning scheme: first short impurities are selected, then long impurities.

The principle of operation is based on the separation of the sorted material by length. For this purpose the cell of the trier surface is used, which has a circular shape in plan and a rectangular trapezoidal shape in cross- section: with an inclined front wall, a vertical back wall and a bottom. Segments with cells are installed in such a way that the inclined front wall of the cell during the rotation of the trier cylinder runs over the processed material in order to facilitate the fall of the material and that the material fallen into the cell is ejected into the tray by the rear vertical wall.

The material processed on air sieve machines, containing long, short impurities and the main grain, enters the rotating cellular trier cylinder of the upper trier (doll collector) 1 through the front receiver and gradually moves to the other end of the cylinder. In doing so, the trier surface entrains upwards the short impurities stacked in the cells, as the cell diameter is smaller than the average length of the main crop. Once upwards, they fall out into the trough and are discharged by the auger through the rear receiver into the waste stream. The long impurities remaining inside the cylinder of the oat picker are discharged through a spigot into the cylinder of the oat picker 2.

Gravity table is a kind of equipment that sorts according to the difference of specific gravity of materials and impurities. The machine is suitable for those cases where the density of fine particle separation is the same. Compared to conventional separators, the accuracy of this separator is higher, but the capacity is low, however, this machine is usually used after pre-cleaning the grain on one of the separators above. And the gravity cleaner already carries out the final cleaning. Densitometric table includes a frame, wind system, vibration system, gravity table.

Principle of operation:

When the machine works, the materials are mainly affected by two forces: wind force and vibration friction force, which you can adjust. And also the angle of inclination. Under the effect of wind force, the materials are in suspension, light materials are on top and heavy materials are on the bottom, the materials are stratified, the vibration of the gravity table makes the heavy products on the bottom rise up and the light impurities on the top flow down under the effect of wind force, thus completing the separation of materials and impurities.

This separator is very close to a gravity separator, having essentially most of the mechanism similar, however it is customised for a specific task - cleaning stones. Grain stone cleaning machines are used in the flour and food industries to create a variety of cereals, extract kernels from sunflowers, pumpkins and other products. In addition, stone separators are used for sorting metal particles from plastic waste, separating metal elements from slag from metallurgical slag, and much more.

The principle of operation of stone separation machines is to separate the product into two fractions based on their specific gravity. This makes it possible to isolate heavy impurities such as stones, glass, metal particles, etc. from purified products such as grains, cereals, plastic waste, metallurgical slag and so on.

A question often asked by farmers is whether it is possible to clean stones with a gravity separator. The answer is no. Or it will not be accurate enough. A different kind of cleaner has been invented for this task for a reason.

Here is also such a wonderful separator.

The modern optical (also called) colour sorter uses up to 3 visible wavelengths, providing excellent colour recognition, and thanks to InGaAs technology it effectively removes complex foreign materials, ensuring maximum food safety. The principle utilises two visible wavelengths. This makes it possible to detect not only light and dark defects, but also other colour variations. We can say that this is the first separator that has ii technology, or rather its primitive algorithms.

The car is incredible, but strangely enough the first beginnings of it were back in 1931.

In 1931, the Electric Sorting Company pioneered the world`s first colour sorters, which were installed and used in the bean industry. As early as 1937, the optical sorting technology had already been refined and allowed the creation of systems based on the two-colour selection principle. In the following decades, the technology developed by leaps and bounds and optical sorting was introduced into more agricultural sectors.

These machines, although expensive, have become a useful invention. The food industry is only a small part of where they are used. They are also used in the metal, plastics and wine industries.

However, it should be realised that even such a technologically advanced machine will not give you 100% purification.

For best and optimal results, you should have 2-3 types of cleaner at once.

When I started in this narrow field, I realised that many farmers don`t know exactly what they need. What capacity, what type of separator, whether one particular one would suffice. It dawned on me that most farmers don`t know much about this equipment, and the information on the internet is very scattered and unclear. This is how the idea to write this article came about. I decided that I wanted to write about the subject of grain cleaners in a way that was as clear and entertaining as possible.

Most of those cleaners you can find on our site and for one you can’t - you can give your willing order and we will find a individual solution.