BBCA Depolama Sis. Tarim Ins. Ve Mak. San. Tic. A.s products

Storage Systems

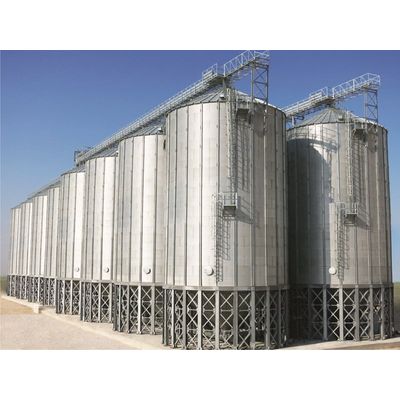

BBCA - Flat Bottom Silo

Flat Bottom Silos deliversity by involving easy assembly resulting in minimal installation costs and highly efficient low cost storage. BBCA Storex offers a capacity range of 25-20.000 tones. BBCA Storex offers diameter-based roof options that help balance performance with price. Also self-supporting roofs with apporiate angle, permitting the optimization of storage capacity through adaptation to the slope of the silo.

BBCA - Hopper Bottom Silos

Hopper bottom silos are typically used in aplications where routine and fast clean out is required or just to reduce the energy and labor cost of material handling. Different hopper angles can be manufactured according to silo diameter, product type to be stored, natural conditions of the place where silo is desired to be erected and customer demands.

BBCA - Round Silos

BBCA Storex offers solutions to it’s customers with steel round silos in order to store flour, bran, semolina etc. granular and powder products. It is manufactured in modules with all bolted combining. Mounting and demounting can be made easily. Modular system is adapted according to customer request. It is designed in demanded sizes and requested capacities. Outside coating, depends on customers demand; Electrostatic powder painted steel Galvanized steel Stainless Steel.

BBCA - Feed Silos

Feed silos are designed for protecting feed from any kind of adverse condition also. Feed silos designed to serve efficiently with it’s advantages such as easy installation, low cost and other engineering details. Feed silos are completely made from hot-dip galvanised steel (S350GD and min.600g/m² coating) Grade 8 (10.9 K) quality bolts and nuts. Special designed feed silo roofs which are manufactured according to the feed stance angle, have more capacity than standart silo roofs.

Cleaning Systems

BBCA - Seperator System

High capacity, high sifting property according to grain type at minimum space. High Performance. Classitication easiness in cleaning. Coarse grained offal gets separated and thrown out with the help of screw conveyor inside the grid riffle at product Inlet. Clean product division over the sieve with the help of cylinder under the product inlet. Proper and controlled division over the sieve of raw material to be cleaned with the help of feeding drum. Multiplex sifting system. The advantage of air sucking from backside and height.Aspiration system with high performance. 2 pieces of screw conveyors have been used for glumes to be thrown out inside the upper air sucking. High capacity air canal.