5 products found

Boltt Agro Technologies products

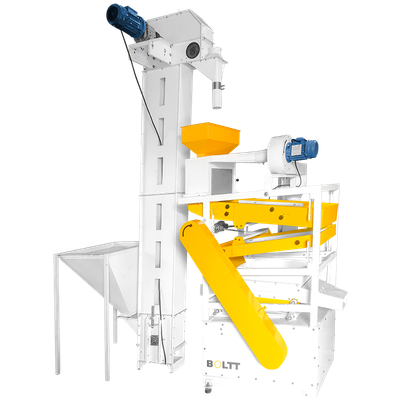

Boltt - Pulse Processing Plant for Seeds, Pulses, and Grains

The Pulse Processing Plant offered by Boltt Agro Technologies is engineered to provide a comprehensive solution for the processing of pulses, seeds, and grains. Manufactured using advanced tools and cutting-edge techniques, the plant is designed to be compact and efficient, showcasing features such as low power consumption and minimal maintenance requirements. Innovatively designed, it supports various processing activities including cleaning, grading, separating, destoning, and sorting. The plant is equipped with an improved drive and thrust system for durability, and its user-friendly feed control handle makes operation straightforward. Additionally, Boltt Agro Technologies ensures robust customer support and technical assistance, facilitating hassle-free installation and addressing any operational challenges that may arise.

Boltt - Seed and Grain Cleaner

The Cleanplus Machine from Intech is engineered to effectively clean a wide range of grains, seeds, and spices, offering an advanced solution for seed and grain processing facilities. The machine's versatile design allows for efficient operation with minimal energy usage and maintenance, optimizing productivity and cost-effectiveness. Its compact structure incorporates an innovative drive and thrust system, ensuring seamless installation and straightforward operation. With the ability to manage feed control easily, it enhances process accuracy while reducing downtime. Boltt Agro Technologies supports this product with robust after-sales service, providing essential technical assistance for any operational challenges. The Cleanplus Machine is ideal for diverse applications, including cleaning, grading, separating, destoning, and sorting of seeds, pulses, and grains, making it an indispensable tool for agricultural processing.

Boltt - Pulse Processing Machine for Cleaning and Destoning

The Pulse Processing Machine by Boltt Agro Technologies is designed with advanced features suitable for the efficient processing of pulses. This multifunctional machine is engineered to manage cleaning, destoning, grading, and sorting tasks, making it ideal for various seeds, pulses, and grains. It is constructed with high-quality components ensuring long-term operational reliability and low maintenance. The machine boasts a compact design and is equipped with an improved drive and thrust system, optimizing performance while ensuring low power consumption. Its user-friendly interface includes a convenient feed control handle for easy adjustments, and it supports hassle-free installation. The company provides robust after-sales support to address any technical challenges, ensuring continuous customer satisfaction. The machine is manufactured with innovation in mind to adapt to new agricultural technologies, maintaining its position as a leader in seed processing solutions.

Boltt - Seed Cleaning Machine

Boltt Agro Technologies offers Seed Cleaning Machines designed for various capacities, suitable for a wide range of seeds and grains. These machines incorporate premium quality components and advanced technology to ensure enhanced robustness and durability. They feature a compact design with low power consumption and minimum maintenance requirements. The machines provide improved drive and thrust capabilities, making installation hassle-free and operation user-friendly with an easy-to-use feed control handle. Their wide application includes cleaning, grading, separating, destoning, and sorting of seeds, pulses, and grains. The company also emphasizes customer satisfaction by providing strong technical support for addressing any problems encountered after purchase.

Boltt - Grain Cleaning and Destoning Machine

The Vibro Destoner by Boltt Agro Technologies is designed for effectively separating stones, pebbles, glass, and other high-density impurities from grain streams. This high-efficiency cleaner incorporates vibro motors which contribute to its compact design and low power consumption. The destoner is equipped with improved drive and thrust systems, ensuring ease of installation and user-friendly feed control through a handle. Its design emphasizes minimal maintenance requirements and includes robust after-sales technical support. Suitable for various plant setups, it caters to diverse applications including cleaning, grading, separating, destoning, and sorting seeds, pulses, and grains. Its throughput adjusts based on the product type and contamination levels, making it versatile for numerous agricultural processes.