- Home

- Companies

- BrimaPack BV

- Products

BrimaPack BV products

Vegetables Packing Solution

BrimaPack - Vegetable Packaging Machine

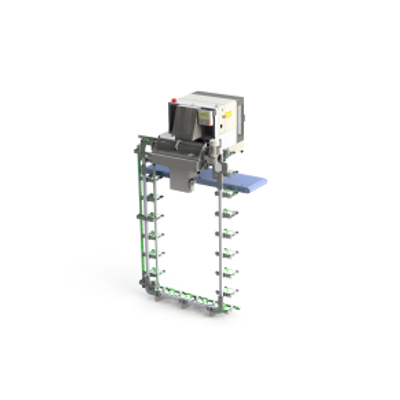

The VePack 200-PH is the stand alone module for pack house operations. This basic system, with manual infeed, is perfectly suited for low cost packing of various products. Either plain or pre-printed film can be used. Each system can be combined with automatic labelling and/or printing, saving additional labor, enhancing the product presentation and ensuring product identification. XL versions of the machine offer extended film sizes, up to a width of 650mm, especially intended for large products.

BrimaPack - Vegetable Packaging Machine

The VePack 200-PHH is equipped with a compact, automated, horizontal in-feed system (rotating table). This in-feed works as a “buffer”, giving the operator the possibility to reach maximum capacity. There is also more flexibility in the number of people working on the packing machine. From one person feeding one machine, to two people feeding four machines (in case of pre-cleaned produce).

BrimaPack - Vegetable Packing Stations

The most cost effective way of packing vegetables is by using the packing system in the field. For this BrimaPack has developed a range of harvesting headers. At field level the workers cut & clean the product and put it in in-feed systems which transport the vegetables to the packing machine(s). After packing the vegetables, processing is continued in state of the art packing and boxing stations. On Iceberg lettuce Rig headers the VePack 200 PRV modules are used but also various flow pack systems can be integrated.

Harvesting Headers for Field Packaging

BrimaPack - Harvesting Header System

The Columbia harvesting header system is customer optimized to achieve highest productivity. In the optimal configuration the cutters are in a kneeling position, the most efficient and ergonomic working position. Each cutter is assigned to specific rows and to a specific in-feed system(s). The header also allows produce to be cut in a conventional working position. The cutters are always facing the produce, making this system suitable for wheeled and tracked drive units. By using tracked rigs the system is not depending on driving furrows or bed configurations.

BrimaPack - Harvesting Header System

The Atlantis harvesting header system is the packing solution based on conventional / traditional harvesting systems, and can easily be used on fields with different planting concepts. The cutters can be assigned freely (within limits) to the different in-feed systems, and iceberg rows. The Atlantis header system itself can be operated in both harvesting directions, forward and reverse. The header is suitable for wheeled and tracked drive units. The foldable roof shields the workers against various weather conditions.

BrimaPack - Self-Propelled Gantry Harvester

The Discovery is a self-propelled Gantry style harvester, designed to meet specific regional requirements, such as those found in the United States. The system has multiple packing units, box erecting and packing stations and logistics integrated into the harvester. The combination with the side off-load, for the packed boxes to a transportation trailer on the side, makes this system the perfect fit into existing Gantry style operations.

Agriculture Carrier

BrimaPack - Self-Propelled Tracked Carrier

The VeTrac is a self-propelled, electro driven, caterpillar tracked carrier. This drive system results in a very low and efficient fuel consumption, low noise emission and is uniquely precise on driveability. The Vetrac can be delivered in standard configuration or Tailor-made to customer preferences.

BrimaPack - Self-Propelled Harvesting Twin-Axle System

The Rover rig is a self-propelled, electro driven, 2 axle system. The Rover is self-propelled while harvesting and towed during field change giving maximum efficiency and flexibility. The large working platform folds into a compact trailer unit in less than 15 minutes.

Bundling & Options

BrimaPack - Bundling Harvesting Systems

With these systems, you can bind up to 3.000 bundles per hour with label or up to 4.800 bundles without label, without any stress. We have a wide experience in binding of herbs, spring onions, leeks, carrots, spinach, asparagus, soup packages and more.