- Home

- Companies

- Cimas S.r.l.

- Products

Cimas S.r.l. products

Feed Milling Machines for Efficient Livestock Feed Production

Cimas - Sensor-Controlled Vertical Cooler with Grids for Efficient Product Cooling

The vertical coolers have been specially designed for uniform cooling of the hot diced product just came out from the press. The material to be cooled is introduced into the machine from above, passing through a rotary valve. The hot product falls inside the refrigerator and leans on the lower level, where the grids are installed, one fixed and two mobile, allowing its ventilation and exhaust. The level of the product to be cooled inside the body of the machine is controlled by a sensor which controls the opening of the lower grid only if the material has reached the predetermined level and instead closes the drain when the level of the product is lower than the preset level.

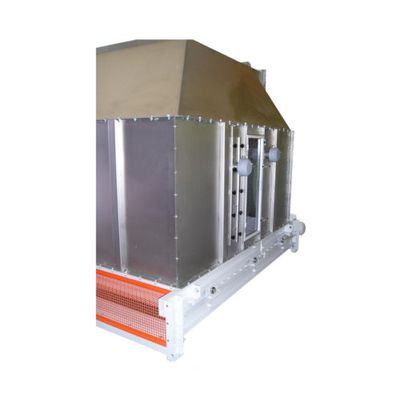

Cimas - Model REO - Industrial REO Series Horizontal Cooler Dryer

The coolers horizontal dryers of REO series have been studied specifically for cooling and uniform drying of granular or pulverulent products of any nature. The REO is constituted by a casing consisting of two separate rooms (a drying and a cooling) comprised of four uprights, they raise the whole structure of about 300 mm with respect to the bearing plane, by an air exchanger – steam, an aspirator and on a stainless steel hood, from the conveyor belts to elements articulated microperforated comprised of transport chains guided on rails polizene, by a group of transmission.

Cimas - Model SR - Industrial Oscillating Sifter for Foreign Body Removal in Granular Products

The oscillating sifter is used to remove foreign bodies of different sizes from a granular product flow in process. The machine consists of a metal case to free oscillation, bound to a base structure via suspension with articulated joints. Inside the bed are fixed two sieves with wood structure, removable and easily inspected: the upper separates the product from the impurities of large size and the lower eliminates small scraps. The separator can be adapted to all cleaning products by the simple replacement of the sifting elements. The machine is combined with a pneumatic sifter to obtain a further elimination of light fractions present in the product.