- Home

- Companies

- Delpimak Makina

- Products

Delpimak Makina products

Cleaning and Recovery Systems

Delpimak - Double Trough Precision Grading Machine

Pulses, nuts, seeds, etc. that have been pre-cleaned or do not need to be cleaned before. It is designed to separate different sizes and fractures in grain structured products. It is generally used as the final control sieve in the process.

Delpimak - Single Boat Precision Grading Machine

Pulses, nuts, seeds, etc. that have been pre-cleaned or do not need to be cleaned before. It is designed to separate different sizes and fractures in grain structured products. It is generally used as the final control sieve in the process.

Delpimak - Seed Spraying Machine

The seed spraying machine is used to coat the seeds with pesticides to protect them against pests and fungi.

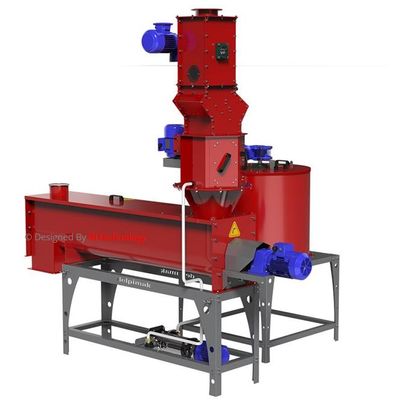

Delpimak - Three Trough Precision Cleaning Machine

Legumes, nuts, seeds etc. It is designed to separate foreign substances in grain structured products. It separates light foreign materials by vacuuming with the hood on it. It separates small, thin and powdery products from the net product with the help of sieves. It can also be used for dyeing the cleaned product.

Transport and Transfer Systems

Delpimak - Standard Type Horizontal Elevator

Pulses, seeds, wheat etc. It is a machine used to transport agricultural products and highly fragile industrial raw materials from one point to another during the process or during packaging. It is preferred because it does not damage the product during transportation.

Delpimak - Standard Type Vertical Elevator

Pulses, seeds, wheat etc. It is a machine used to transport agricultural products and highly fragile industrial raw materials from one point to another during the process or during packaging. It is preferred because it does not damage the product during transportation.

Delpimak - Tilting Type Vertical Elevator

Pulses, seeds, wheat etc. It is a machine used to transport agricultural products and highly fragile industrial raw materials from one point to another during the process or during packaging. It is preferred because it does not damage the product during transportation.