Ekko Maskiner A/S products

Inload - Box Tipper

EKKO - Model EM 1161 - Hydraulic Box Tipper

Hydraulic box tipper for big boxes. As standard with manual operation of hydraulic valve. ?Also available with remote release for truck. ?Non-standard measures for your boxes can be made to your specification.

Ekko - Model EM 1171 - Hydraulic Box Tipper with Centertip

Hydraulic box tipper for big boxes. As standard with manual operation of hydraulic valve. ?Also available with remote release for truck. ?Non-standard measures for your boxes can be made to your specification.?Hydraulic box tipper with center tip is designed to place on top a inloading silo.

Inload

Ekko - Model EM 1120 - Inload Elevator

Inload elevators with rubber belt and cleats. ?Delivered with mechanical speed variator for dosing of discharge

Ekko - Model EM - Flow Silo

Flow silo with automatic height adjustable conveyor bottom.?The bottoms raise automatically depending on the product content and desired flow. Ekko Flow silo is available with photocell and electrical controls

Washing

Ekko - Top Seperator

Top separator used to filtering out peaks and other plants, which is not desired on in production. The top separator is usually associated with a waste strip or similar, for disposal of plant residues.

Grading

Ekko - Model EM - Diameter Roller Grader

The diameter grader from EKKO Maskiner A/S works with chain driven stainless rollers moving forward with frequency controlled speed. The machine is built up modular, and can be delivered to sorting from 3 to an endless number of sizes.

Ekko - Model EM 1430-1454 - Lenght Grader

EM 1430-1454 length graders for carrots have capacities from3-8 t/h.?The machines grade the carrots by length over stainless vibrating riddles with infinitely adjustable spacing.?The machine is designed in such a way that the carrots do not accumulate in the riddles, and it is available with 2, 3, or 4 grading.?The length graders are delivered complete with internal electricity and are prepared for transverse belts for the individual grading.

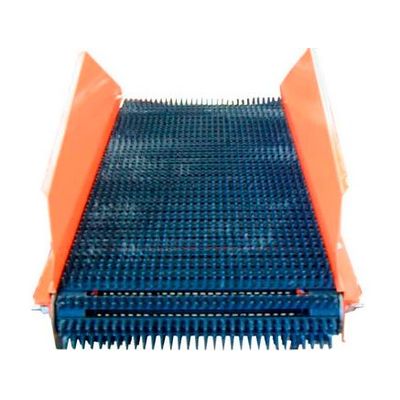

Ekko - Model EM - Screen Grader

For careful grading of potatoes and onions, capacities of 6-45 t/h.The machines are equipped with screen belts with mesh sizes from 20 to 85 mm, and in widths from 600 to 1800 mm. With this system, any grading solution can be structured, as the system consists of modules which can be combined in several ways. The graders are provided with elastic drop dampers in order to break ?the fall between screen belt and conveyor belt.?Moreover, the screen graders are fitted with a freely running lifting roller which ensures that the products are loosened from the screen belt before the draw roller. All types from 900-1800 mm are equipped with transverse belts and separate adjustable speed motor for shaker.