- Home

- Companies

- Elecster OYJ

- Products

Elecster OYJ products

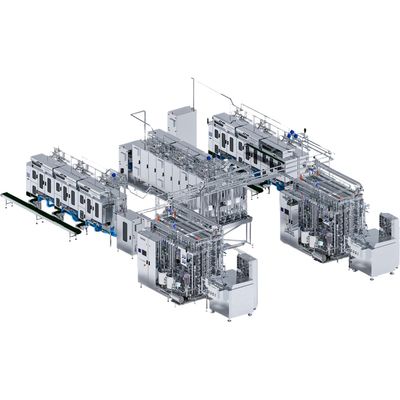

Complete UHT Processing Line

Elecster - Model UHT - Complete Processing and Packaging Machine

Compact system with optimized capacities. Elecster processing and packaging machines are tailored to work as a complete line. This is a guarantee for high performance and production efficiency. No need for expensive aseptic buffer tank or separate CIP system, which makes Elecster complete UHT line a cost efficient and space saving solution. Elecster equipment is designed, assembled and tested in Finland. Test runs are performed on the entire UHT line at the Elecster factory. For this reason, the installation and commissioning of the line is effortless and fast. Elecster complete UHT line output capacity is from 800 liters per hour up to 10000 liters per hour.

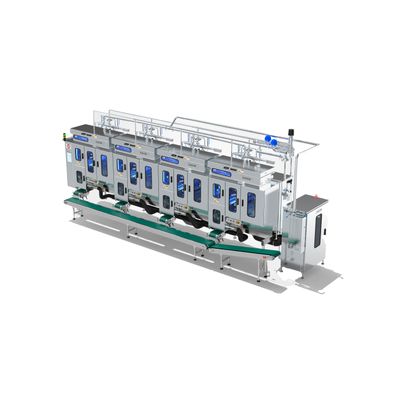

Elecster - Aseptic Pouch Packaging Machines

Reliable and lasting seams: Reliable and lasting seams are guaranteed by permanently heated sealing devices. The temperature of the heat sealing is adjusted with an accurate PID control. The film is sealed inner surface against inner surface. The form of the package is pillow pouch.

Accurate dosing and low packaging material loss: Elecster technology enables to get high quality pouch, vanishing leakage problems and outstanding image printing. Volume based dosing unit is a guarantee for stable and accurate dosing. Automatic film track control and sealing device temperature control ensure minimal packaging material loss.

Elecster - Dairy Product Sterilizers

Long experience, deep knowledge, high quality components and materials assures the Elecster sterilizer’s high product quality and food safety. Sterilizer’s construction is stainless steel and complete system includes homogenizer and CIP unit. The capacity and the process temperature of the sterilizer can easily be adjusted to fit different capacities and products. Products like pasteurized milk, powdered milk, flavored milk, low fat cream and drinking yoghurt. Sterilizer has low utility consumption and the heat regeneration level is approx. 90%. Steam is used as the heating energy source.

Aseptic Pouch Filling Machines

Elecster - Aseptic Pouch Packaging Machines

Reliable and lasting seams: Reliable and lasting seams are guaranteed by permanently heated sealing devices. The temperature of the heat sealing is adjusted with an accurate PID control. The film is sealed inner surface against inner surface. The form of the package is pillow pouch.

Accurate dosing and low packaging material loss: Elecster technology enables to get high quality pouch, vanishing leakage problems and outstanding image printing. Volume based dosing unit is a guarantee for stable and accurate dosing. Automatic film track control and sealing device temperature control ensure minimal packaging material loss.

Elecster - Model FP-2500 & FP-5000 - Pasteurized Pouch Machines

Elecster Company is making as well packaging machine for milk pasteurized milk products, like liquid milk and sour milk products. Most of the machines are single liners FP-2500 or double liners FP-5000. Usually the capacity of the machine is 2500 bags/hour or 5000 bags/h. However with certain elements the capacity can be updated even higher. We have paid special attention for the easy usage of the machines. Machines are PLC-controlled, which allows to set the start up parameters for different products and packages sizes on the memory. It is very handy, just push the button and move over to next product smoothly. For daily operation FP-2500 is easy to learn and usually as a part of the installation we are usually giving training session. The same packaging machine can be used for different sizes 200 ml- 1000 ml. Changing the size is easy and flexible.

Others

Elecster - Downstream Equipment for Automatic Pouch Handling

Elecster is the leading company in the world as a system supplier for UHT lines, Aseptic Pouch Filling Machines and ecological Pouch Packaging Materials. With over 50 years’ experience of engineering and manufacturing of dairy machinery and packaging material it has developed the superior know-how of compatibility required for milk pouch technology.