Fan Way Fertilizer Machinery products

Compost Turner

Fan-Way - Model 9FY-FYD Series - Self-Propelled Compost Turner

The self-propelled organic fertilizer compost turner is the main machine of the specialized complete equipment in the organic fertilizer production/plant. It adopts four-wheel drive design which only needs one person to drive and the operation is very easy. When the machine starts to work, it straddles the strip-type compost heap and the rotary cutter shafts under the rack stir and mix the material. The operation can be completed not only in the open area but also in the workshop and greenhouse. One of the machine’s technical breakthroughs is to integrate the crushing function at the later stage of the material fermentation. With the continuous dehydration of the material, the cutter shafts can effectively crush the caking formed during the fertilizer fermentation. Thus the production does not need to equip an additional crusher, the crushing efficiency is greatly improved and the cost is largely reduced.

Fan-Way - Model FY-9FYD Series - Hydraulic Compost Turner

The hydraulic compost mixer machine is the professional machine for horse manure compost and other organic materials fermentation. It adopts advanced hydraulic operating system, pull rod power steering operation and crawler-type running mechanism. Such structure makes sure it offers strong power and easy operation for the compost turning of materials.

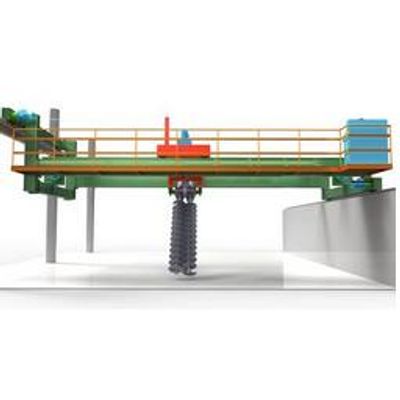

Fan-Way - Model FY-SLXFDJ-325 - Double Helix Compost Turner

Double helix compost turners are used for making compost piles, fermenting and composting organic waste, such as animals & fowls manure, sludge waste, sugar filter mud, and straw sawdust etc. There are two spiral arms moving in the trough. Materials can be mixed and fermented in the trough for 7-10 days. Temperature should be between 60-70?; Moisture content should be between 40-50%.

Fan-Way - Model FY-FJ Series - Groove Type Compost Turner

This organic fertilizer compost turner, which includes groove type compost turner and groove type hydraulic compost turner, is the most widely-used aerobic fermentation machine and compost turning equipment. It includes walking fermentation groove, walking track, power-pick device and other parts. The working portion of the compost turner machine adopts advanced roller drive. There are adjustable type and non-adjustable type for choice. The groove type compost windrow turner is widely used for dealing with animal manure, household garbage, sludge, crop stalks and other organic wastes, and also can be used in feed fermentation.

Fertilizer Crusher

Fan-Way - Model FY-NSFS - Dust-Free Cage Crusher

The dust-free cage mill is a middle-size horizontal cage bar crusher and it is good at crushing raw materials with the moisture content below 40% especially the material with high hardness.

Fan-Way - Model FY-LSFS Series - Fertilizer Chain Crusher

Vertical Chain Fertilizer Crusher Introduction &Application fertilizer crusherOur vertical chain crusher is suitable for both bio-organic and compound fertilizer production line. It can crush large lump materials into small granules. But its most common use is to crush sub-standard fertilizers after screening process, so this fertilizer crusher is always placed behind rotary drum sifting machine in the fertilizer production line. Except for fertilizer plant, this type of fertilizer crusher can also be used in chemical industry, building materials industry, mining industry and so on. The feed opening and discharge outlet of this machine is rationally designed, promising that materials can be fully and evenly crushed.

Fan-Way - Model FY-BSFS Series - High Moisture Materials Crusher

Our high-efficiency organic fertilizer crusher is a new reversible type crusher. It has a strong adaptability to the moisture content of the materials especially the matured waste after fermentation and other materials with the moisture content less than or equal to 30%. The granulation success rate of the machine reaches 20% to 30% which can meet the requirement of the common fertilizer production. The crushing size can be adjusted according to customer’s demand. This fertilizer crusher greatly shortens technological process, reduces equipment investment and saves operating cost, so it is the ideal machine for fertilizer production. Semi-wet materials crusher is the specialized crushing machine manufactured based on continuous research, improvement. It combines advanced technology at home and abroad, and completely solves the problem of crushing high moisture materials. It plays an important role in fertilizer production.

Fertilizer Mixer

Fan-Way - Model FY-YPWL Series - Flat Pan Mixer

The flat pan fertilizer mixer is mainly applied to compound fertilizer plant. By using the optimum quality material and leading technology, this fertilizer mixing machine reaches the industry norms and international specifications. It is popular among our customers due to its high-efficiency, competitive price, easy-operation, and low maintenance cost. In the compound fertilizer production line, it is placed before fertilizer granulator, to evenly mix kinds of raw materials before granulating.

Fan-Way - Model FY-SZ Series - Horizontal Fertilizer Mixer

The horizontal fertilizer mixer, which is the new-generation mixing equipment developed by our factory, is high mixing uniformity, less material residual. This kind of fertilizer mixing machine is suitable for blending the formula feed, concentrated feed, additive premix, and raw materials of organic and compound fertilizer. There are two types of horizontal blenders: one is single shaft mixer, and the other is twin shaft mixer. They are the most common fertilizer mixing machines in organic & compound fertilizer production. As for twin shaft fertilizer mixer, it has the advantage of higher capacity and higher mixing efficiency. The two axes are in relative rotation during working so that raw materials can be evenly mixed, being widely used in organic fertilizer manufacturing.

Fertilizer Granulator

Fan-Way - Model FY-JCZL Series - Spherical Organic Fertilizer Granulator

New type organic fertilizer granulator is also called wet granulator or stirring tooth granulator. It is a newly developed granulator used for granulating various kinds of fermented organic materials. The raw materials need not to be dried before granulation, saving energy and production cost. The granules produced by this fertilizer making machine are spherical type, which is easy to apply.