Friesla products

Friesla - Modular Meat Processing Systems

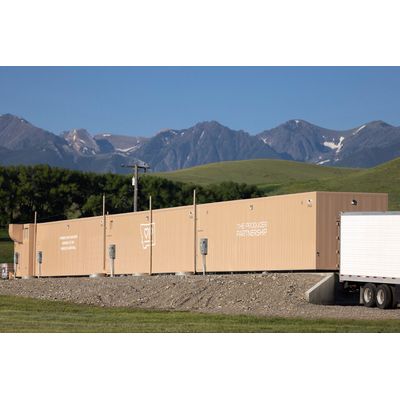

Friesla provides modular meat processing systems that empower local farmers and ranchers to maintain control over their meat processing operations. As opposed to traditional, large-scale processing facilities, Friesla's systems are made up of modular units that cover all stages of meat processing, from slaughter to packaging and sale, ensuring compliance with USDA standards. These systems are designed to be cost-effective and scalable, requiring less power and resources than conventional facilities. Additionally, they offer flexibility to expand, rearrange, or relocate as operational needs change. With integrated hardware and software for traceability and workflow management, Friesla's systems are equipped for multi-species processing including beef, bison, pigs, sheep, and more. The modular design facilitates quicker setup compared to traditional brick-and-mortar facilities. Friesla systems can be depreciated over seven years, and the company provides comprehensive design, installation, and training support to ensure operational efficiency from inception.

Friesla - Mobile Meat Harvest Unit

Built with a heavy duty steel frame and rugged aluminum body construction, the Friesla Mobile Meat Harvest Unit is built to be pulled down the road. Over the past 15 years, this USDA-compliant unit—now in its fifth generation of design—has been used to process meat on farms and ranches in the USA, Canada, South America, and Africa.

Friesla - Cut and Package Module

Friesla's Cut and Package Module is designed for efficient on-site processing of chilled animal carcasses. Built on robust steel frames in the USA, this module integrates essential equipment for meat handling and packaging, allowing operators to maintain quality control throughout the initial stages of meat processing. It is a key component of Friesla's Meat Processing System and adheres to USDA regulations. Features include a meat rail hanging system for effortless carcass handling, stainless steel polytop cutting tables, and specialized equipment like band saws, grinders, and vacuum packaging machines, customized during the development phase. Bright LED lighting, cooling systems, waterproof electrical setups, and user-friendly cleaning features ensure a functional workspace. This module complements Friesla's Mobile or Modular Meat Harvest Unit, facilitating a comprehensive, expandable processing set-up at a single location, optimized for operational growth and efficiency.