Grain Systems Inc - GSI Group products

Storage - Grain Bins

GSI - Model 4022 - Stiffened Bins

Among the tallest bins offered, the 4022 is designed to support the needs of the largest operations and the continued growth of your system.

GSI - Model 4002 - Unstiffened Bins

In 1972, the first GSI bin featured a 2.66” corrugation, unstiffened bin design. This proven design has continued to evolve and grow for today’s operations, and features our precision roll-forming process corrugates accurate sidewall sheets every time. This process assures a tighter fit and increased weather protection. With the original 2.66” corrugation profile, the 4002 is the perfect bin to maintain a historic look and consistent bin height.

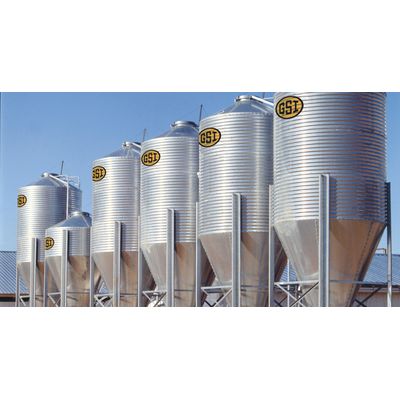

Storage - Hopper Tanks

Model GHT - Hopper Tanks

Designed to handle dry free flowing grain, the GHT fits the needs of small capacity ranges with the increased strength of a grain bin roof.

Model BFT - Hopper Tanks

Bulk Feed tanks, or BFT’s, are a great way to store and protect feed. BFT’s feature a sealed roof and hopper body design to protect grain/feed from moisture and offer easy unloading.

Grain Products - Storage

GSI - Fans & Heaters

GSI - Temporary Storage Systems

Temporary storage systems offer a quick, efficient and cost effective way to increase your storage capacity. For only pennies per bushel you can handle up to 2 million bushels or more.

Conditioning

GSI StirAtor - In Bin Grain Dryers

For over 30 years, the Design III StirAtor has been the most dependable stirator system. Though among the lowest in capacity, the Design III can turn a grain bin into a drying system at a minimum investment. A high temperature, above 10 degree rise, bin dryer has to have a way to dry all the grain to the same moisture. Just running a fan & heater on a bin full of grain will result in 5% grain at the bottom with no moisture removed on the top. GSI’s StirAtor ensures that all the grain is the same moisture, with no wet tank required; all you need is a fan & heater and an auger to fill the bin.