Henan Gate Heavy Industry Machinery Technology products

Gate - Bio Organic Fertilizer Production Lines Plant

Disc granulator in organic fertilizer production equipment is a type of organic fertilizer granulator. The disc granulator is lined with high-strength glass reinforced plastic and stainless steel. It has uniform granulation, high granulation rate, stable operation, sturdy and durable equipment and long service life. fertilizer granulator machine india is much more popular, organic fertilizer production equipment has very low cost. The granulation disc circle adopts an overall circular arc structure, and the granulation rate can reach 93 or more. The disc granulator can continuously output fertilizer, which is convenient for uninterrupted production operations, greatly reducing labor intensity and improving labor efficiency.

Gate - Organic Fertilizer Processing Equipment

The production process of organic fertilizer production plant is mainly to granulate, dry and cool the organic waste which has been fermented and decomposed with water content of about 30%-35% by pulverizing, stirring, etc. Granular organic fertilizer, adding functional bacteria can produce bio-organic fertilizer, adding nitrogen, phosphorus and potassium (total nutrient content less than 15%) can produce organic and inorganic fertilizer, the specific details can be customized according to your needs while installing organic fertilizer production line cost. The scale and product design needs to be formulated according to the characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, plant site conditions, and automation of organic fertilizer manufacturing plant.

Gate - Model PLZ - Batching Machine for Fertilizer Organic Production Lines

We are the automatic accurate batching machine manufacturer and we have our own factory, PLZ series automatic batching machine is mainly suitable for 3 to 10 kinds of the materials feeding , dosing and mixing , which use the PLC for automatic control, with pneumatic cylinder for main quantitative feeding control and prevent the materials dropping from the feed hopper. Materials sent out after mixing with a belt machine automatically.

Gate - Model TH - Bucket Elevator for Organic Fertilizer Production Lines

we are the Bucket Elevator Factory and Bucket Elevator Manufacturer in china for more than 30 years. the Bucket Elevator is designed for gentle handling and are well suited for a broad range of bulk products in the food, agriculture, fertilizer, pharmaceutical, chemical, metallurgical and other industries. The elevating buckets are overlapping at the inlets to prevent spillage and can be selectively tipped at the outlets.

Gate - Model MSSJ-7030 - Single Shaft Fertilizer Mixing Machine for Fertilizer Organic Production Lines

Single Shaft Blade Mixer for fertilizer is continuous fertilizer mixing machinery. For the feeding materials and discharging materials, they are working in the same time. Because its special function, it is usually used in large capacity fertilizer plant line.1.Single shaft mixer raw material dealing:various materials 2.Single shaft mixer application:organic fertilizer production line,compound fertilizer production line,under the dust collector of thermal power plants, it can also be used in chemical metallurgy, mining, building materials and other industries. 3.Capacity:5-8t/h 4.Single shaft mixer advantages:The spiral blade adopts to high anti-abrasion steel alloy, high mixing efficiency, small occupied area;Low noise, the machine use reducer to drive, work stable;reasonable structure, stable work.

Gate - Model GTPJ - Fertilizer Vertical Mixers for Organic Fertilizer Production Lines

The fertilizer Vertical Mixers For Sale is a forward rotation stirring and reverse discharging. It can mix plastic and semi-dry hard concrete. The vertical type mixer machine has the advantages of stable operation, convenient operation, good mixing quality and high productivity.1.Raw material dealing:various materials

Gate - Fertilizer Ton Bag Packing Machine for Fertilizer Organic Production Lines

The utility model has the advantages of high measuring precision, large packaging capacity, environmental protection of sealing agent, high degree of automation, large production capacity, wide application range, simple operation and convenient decoration. The equipment is designed for powders and granular materials such as cement, non-metallic mineral powder, chemical raw materials, etc. It is widely used in building materials, chemicals, food, feed, minerals and other industries.

Composting Series

Gate - Model GTF - Organic Fertilizer Groove Type Compost Turner

Groove Type Compost Turner Capacity: 1-10 tons per hour. Groove Type Compost Turner Raw Materials: agricultural wastes, animal wastes, sludge, food wastes and some other organic wastes. Groove Type Compost Turner Applicated range: fermentation, organic fertilizer plant, complex Fertilizer plant, sludge waste plant, horticultural field and agaricus bisporus plant and so on. Groove Type Compost Turner Advantage:low energy consumption, high production efficiency, low cost and widely using

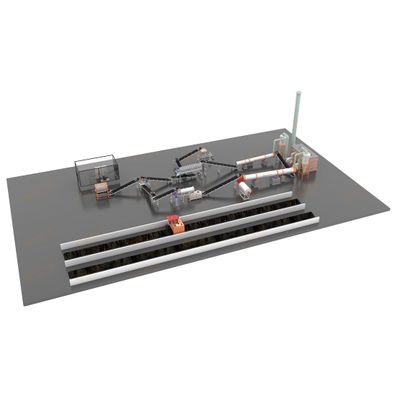

Production Line - Organic Fertilizer Production Line

Gate - Organic Fertilizer Production Line

Bio Organic Fertilizer Production Line use bio fungi/bacteria, all organic wastes, like animal manure, agriculture wastes, municipal waste, food waste, sewage sludge, industrial organic waste, bio organic fertilizer manufacturing plant is for producing bio organic fertilizer, Capacity: 1-50 ton/hour bio organic fertilizer production process Application: small scale bio organic fertilizer production, Bio Organic Fertilizer Production plant Advantages of bio organic fertilizer machine: organic waste recycling, low investment, high return, easy operation, vast market potential, high automation/Crushing Series

Gate - Model GTC - Vertical Crusher for Fertilizer Production Line

Vertical crusher raw material dealing:Gypsum, coal gangue, slag, copper ore,compound fertilizer ,etc, especially the material with higher moisture content. 2.Vertical crusher application:organic fertilizer production line,compound fertilizer production line 3.Capacity:4-12t/h 4.Vertical crusher advantages:Simple and reasonable structure, low running cost;High broken rate, energy saving; Small Affected by the material moisture content;Work noise below 75 decibels (db), less dust pollution;Suitable for crushing medium hard and hard materials.