Maselli Misure S.p.A. products

Maselli - Tomato Analyzer

The TR01 grinding unit is one of the most important elements of the Maselli SV01 quality control station for the check of the quality of the raw tomatoes delivered at the processing plant. In its maximum configuration, the TR01, after having reduced the tomato to juice, can automatically determine Brix, pH, color and the quantity of lycopene of the sample. The “all in one” solution means that the installation times and costs are reduced to an absolute minimum and it makes transfer and reinstallation in other areas quick and easy: all together, these functions make this a unique system easy to be handled and serviced. The TR01 can be delivered in 2 different configurations: when integrated in the SV01 station, it is directly controlled by the PLC; when delivered as a stand alone unit, it comes with a remote pushbutton panel so that it can be activated an interfaced with the data acquisition system.

Laboratory Analyzers - Spectrophotometers

Maselli - Tomato Product Spectrophotometer

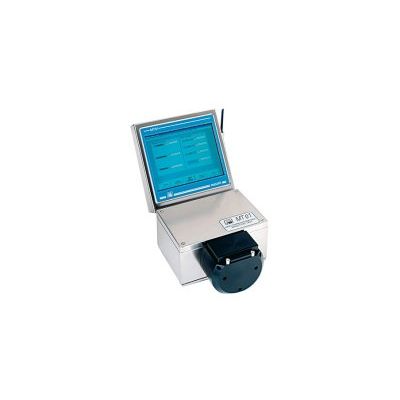

The Maselli LC01 Colorimeter + Spectrophotometer is a laboratory instrument developed to measure the color indices a, b, a/b and L, as well as the Lycopene content in tomato products. It has been designed to be accurate, robust and simple to use: the stainless steel enclosures and waterproof display permit the LC01 to also be used in the processing area The LC01 is able to quickly measure the sample as it is introducing a new innovative method to measure directly the lycopene content of the tomatoes during each stage of the processing. An intuitive software and touch-screen display simplify the interface for all the operations related to graphics, data storage, transfer and printing features. While the equipment does not need frequent calibration, it can be checked using the classic tomato standard BCR red ceramic tile, while using its PVC sample holder with optical glass window for the measurements.

Wine Analyzers -Grapes Maturation

Maselli - Maturity Trend

Wine Analyzers - Grapes Receiving Area

Maselli - Grapes Analyzer

The SA is a sophisticated analyzer able to measure different parameters of a sample of grape must at the time of delivery to the wine processing plant. The standard configuration of the unit is Bx only but, as an option, it is possible to add pH, Total Acidity, color and grapes sanity measurements. The design of the system is modular: you may start with one parameter and add the other ones at your convenience. The analysis cycle (sampling, measuring and washing) is fully automatic and after measurement, the SA displays the results in the selected scale: it can be connected to an external printer and/or to the processing plant’s management system. The sample to be measured may be delivered to the SA both manually and automatically: in the automatic configuration, the analyzer is connected to the Maselli CC05 truck sampling probe by means of the must transfer unit. Even in the full configuration, all the cycle may be handled by only one operator using the joystick control panel.

Maselli - Grapes Analyzer

The LA02 refractometer measures the sugar content and the pH (optional) of a sample of grape must at the time of delivery to the wine processing plant. The unit automatically controls the analysis cycle (sampling, measuring and washing) and displays the results in the selected scale: as far as concerns the washing, the measurement takes place in a basin where the prism is automatically washed after each cycle with a dedicated wiper. In order to handle the measurement data, the LA02 can be connected to an external printer and/or to the processing plant’s management system. The sample to be measured may be delivered to the LA02 both manually and automatically: in the automatic configuration, the analyzer is connected to the Maselli CC05 truck sampling probe by means of the must transfer unit. Even in the full configuration, all the cycle may be handled by only one operator using the joystick control panel.The farmers may see the results of the analysis in a dedicated remote display