- Home

- Companies

- M.R. Dean Ltd

- Products

M.R. Dean Ltd products

Milking Systems

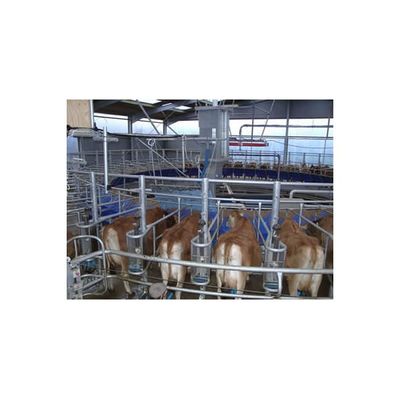

Herringbone Milking Systems

Individual Feeding or Batch Feeding, Automatic.

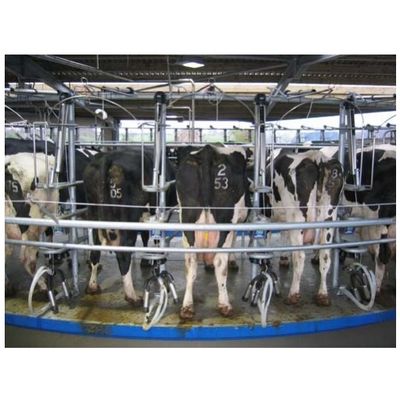

Rotary Milking Systems

Individual Feeding or Batch Feeding, Automatic.

Backing Gates

Yard Backing Gate for Milking Parlours

The Hi-Flow Backing Gate is an electronically controlled backing gate, designed in New Zealand, to be used in rectangular collecting yards. It is designed to keep the milker in the pit, reducing down time and increasing cow throughput in the milking parlour. The backing gate can be fully controlled from the pit in the milking parlour and also from behind the backing gate itself. A pull cord is fitted running the length of the pit, to move the gate forward - no need to walk to the back of the pit just to press a button to get a few more cows. The backing gate is designed to reduce stress for both the person milking the cows and also for the cows themselves. The backing gate is not electrified, cows are encouraged to move using a hock bar fitted to the backing gate, this helps to reduce stress in the cows.

Feeding

Herringbone Feeding System for Livestock Management

Little things mean a lot...Especially when it comes to choosing a feeding system that is going to serve faithfully and reliably, day in, day out.

Dump Box Rotary Feeder

The Dump Box Feeder uses a `dump` principle to deliver rations at high speed to the centre of mangers fitted to rotary parlours. A large bin is provide for concentrate storage. An electric auger system is recommeded to deliver concentrate to the bin during milking. Twin electric feeders fill a dump box and optical sensors detect the correct position for the ration to be `dumped` into the centre of the manger. At this precise moment, the diaphragm valve opens a flap and `dumps` the ration without halting or slowing the rotary table / platform. The Digital Control prevents feeding from occurring if the table reverses for any reason.

Out-of-Parlour Feeding System

Open 24 Hours - Up to 12 feed and 3 no-feed periods in any 24 hours. All are farm programmable and may be changed at any time. The no-feed periods deny rations to all cows and are particularly useful just prior to milking. ATL Rapid Start - Because you want your new ATL Out-Of-Parlour Feeding system up and running quickly, we initially link your cows to their tags and pre-program the control unit to save you money.

Other Products

HEATIME - Cow Heat Detection System

The HEATIME system is based on continuous monitoring of individual cow activity. The activity is detected by a durable neck tag with a unique sensor. This tag records the cows movements (not just its footsteps) and stores this data. When the cow passes underneath the ID unit the tag is triggered and sends the data to the HEATIME control box.