Newman Machine Company, Inc. products

Knife Grinders

Newman Zone - Model G-200 - Rotary Knife Grinder

The Newman G-200 Rotary Knife Grinder is recommended for precision grinding of chipper, planer and other specialty knives that require making a straight pass across the face of the knife. The unique design of these grinders provides a rotating disc with four adjustable bars for grinding bevels from 25 to 40 degrees. It is also equipped with inside bars for grinding planer knives on a fixed 30 degree bevel. Various knife stacking features are available.

Newman - Model G-280 - Rotary Knife Grinder

The Newman G-280 Rotary Knife Grinder is recommended for precision grinding of chipper, planer and other specialty knives that require making a straight pass across the face of the knife. The unique design of these grinders provides a rotating disc with four adjustable bars for grinding bevels from 25 to 40 degrees. It is also equipped with inside bars for grinding planer knives on a fixed 30 degree bevel. Various knife stacking features are available.

Shaving Machines

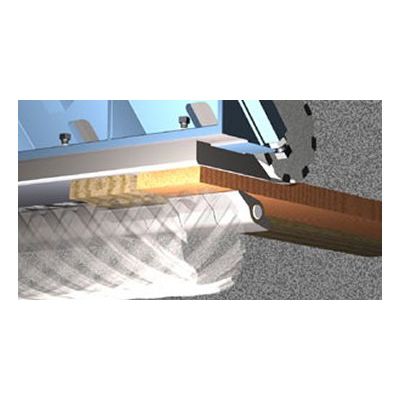

Newman - Model LS-1029 - Shaving Machine

The Newman LS-1029 Whole Log Shavings Machine produces high quality shavings from whole logs suitable for agricultural bedding. Heavy duty construction provides for high levels of productivity, durability and smooth operation. Log Hopper Capacity: 29” wide x 37” high x 52” long.

S-382 Retro Fits

Automatic Cut Control

The A.C.C. is a sectional, mechanical device designed and developed by Newman Whitney to offset the fixed bottom head cut found on conventional knife planers. This device provides more equal cut distribution between the top and bottom cutterheads. Varying bottom head cut provides more equal distribution of hit-and-miss surfaces on both sides of the lumber which results in increased yield and lumber grade improvement. Yield increases of 5% to 20% can be obtained with use of the A.C.C. option.

Digital Thickness Indicator

The Accurate Proscale is now a standard feature on most of our Rough Mill Planers. The digital indicator from Proscale provides quick and easy setup for changes in finished lumber thickness. This option coupled with the power hoist retro-fit facilitates push button dimension changes, reducing the delays involved with the numerous thickness changes required in today`s modern planer mills. The readout mode can easily be changed between inch (fraction and decimal equivalent) and metric. Following regular knife maintenance, recalibration is simple and easy.

Machine Enclosure

High performance, fiberglass machine enclosures are available for all NEWMAN*WHITNEY Roughing Planers. Modern clam shell design along with sound dampening materials offer both reduced noise levels, increased safety and excellent machine access. On-site Newman installation is available or the unit can be customer installed. Detailed instructions are available.