Ottevanger Milling Engineers products

Storage & Handling

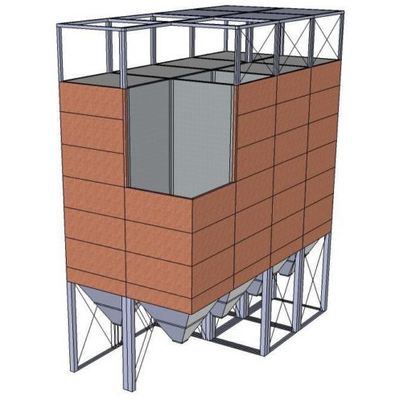

Ottevanger - Square Silo for Bulk Goods Storage

A square silo provides 25% more storage capacity than round silos on the same floor area. So for bulk goods, square is the right shape for maximum storage capacity. First of all, a unique property of our square silo are the ultra-smooth flat walls. Even the most difficult products leave our silos without any problem. As a result of our clever design we can ensure that there are no weld seams on the inside of the structure. Yet the silo still retains its strength.

The rectangular silo concept is characterized by an optimum storage capacity and flexible layout options. A clever design produces the best possible product discharge with maximum storage capacity. With a square silo, you are also investing in a safe, hygienic working environment.

Ottevanger - Galvanised Steel Cylindrical Silo for Long-term Storage

Round silos are the usual choice when storing large quantities of raw materials (if there is a need for long-term storage). A range of storage capacities, heights and diameters are available. These cylindrical storage bins are manufactured from galvanised steel with reinforcement.

Milling & Structurizing

Ottevanger - Roller Mill Mesh Screen Protector Roll

The Protector Roll regulates an even spread (flow) of grains, cereals, or mixture over a mesh screen into the Roller Mill. By cleaning the product flow from excessive impurities, the Protector Roll protects the Roller Mill from wear or possible damage which could lead to undesirable downtime.

Mixing

Ottevanger - Single Shaft Paddle Mixers

The strict demands posed on the mixer in the processing industry were the starting point for the development of the Ottevanger high accuracy mixers. One of the main concepts is our single shaft paddle mixers. These Ottevanger paddle mixers are designed for mixing dry powders and granulates irrespective of their bulk density or shape. Liquids can be added during the mixing process. The Ottevanger paddle mixers are equipped with pneumatic operated bomb doors under the full length of the mixing trough. This shortens the discharge time to approximately 15-20 seconds. The mixing plant can operate fully automatic with a capacity up to 15 batches per hour.

Ottevanger - Double Shaft Paddle Mixers

Ottevanger double shaft paddle mixers, type DPMA, realizes high mixing capacity with a relative small mixer content. Our double shaft paddle mixer DPMA has a mixing time, depending on the product type and quantity, from 30 to 60 seconds. The mixers are available with capacities from 500 to 12.000 liters. Its mixing accuracy meets the very stringent requirements, while damage to products is prevented because of extra wide bomb doors. This ensures a residue and dust free design, due to unique sealing principle. The success of this fast mixing principle is a result of the fluidized zone, in which the particles have a complete freedom of movement. Therefore they are able to mix themselves homogeneously in a state of weightlessness. The Ottevanger paddle mixers are designed for mixing dry powders and granulates irrespective of their bulk density or shape. Liquids can be added during the mixing process.

Ottevanger - Continuous Mixers

The Ottevanger continuous mixers are pre-eminently suitable for equal dividing liquids into powdered material (for instance, molasses into mash). A dosing pump with adjustable drive can be supplied with the mixer. The quantity of liquid is exactly registered by de flowmeter which is suitable for automatic control. The screw feeder ensures an even flow of meal into the mixer.