Riela Karl-Heinz Knoop e. K. products

Grain Cleaning Plant

An up-to-date grain plant is hardly conceivable without a cleaning plant connected to the intake station even if the grain is only used internally.

The dust pollution is reduced, undesirable admixture and green parts are sorted out and the performance of the following conveying and drying plants is optimized. According to the process, pre-cleaners, sieve cleaners and combined units which combine the sieve cleaning with the pre-cleaning, can be used. It is important to consider the cleaning capacity in a way to avoid a bottleneck at peak time

Cleaning Technology

Riela - Pre-cleaner

Pre-cleaner work according to the air sifter principle. The ingredients, which are lighter than grain, thoroughly extracted and separated. The RIELA pre-cleaner type Air-Seed is an effective pre-cleaner for cereals, grass seeds, legumes, oilseeds, granules etc. The built-in product distributor ensures a better cleaning result.

Riela - Prof Seed Cleaner

RIELA cleaning machines for the main cleaning of cereals, legumes, oilseeds and similar varieties. Effective cleaning is the gateway to professional grain management, ensuring your success in the warehouse and avoiding losses, mold, bacteria, microorganisms and other pests. Cleaner performance can be matched to the respective system concepts.

Drying

Riela - Mobile Dryer

RIELA-Continuous or re-circulating dryer mobile in aluminium design: galvanized version, perforated stainless stell plates, warm air generator with branded oil burner, for grain, green spelt, legumes, maize, rape and sunflowers, optional available in stationary version, available with direct or direct/indirect heating (by switching), optional supply with natural gas or propane instead of oil, energy input oil only 1,1 l per ton heavy grain per 1% humidity extraction, energy input natural gas only 1,5 m³ per ton heavy grain oer 1% humidity extraction.

Riela - Tiltable Mobile Dryer

With conical formed cascades for constant drying. Rectangular drying tower made of special aluminium. Frame and supporting parts galvanized. With storage section. For gentle cleaning of grain, rape, maize, sunflowers and legumes. With two bucket elevators positioned sideways. Warm air generator optional for propane, natural gas or oil (direct heating) on a separate trailer. Sensor for filling and emptying. Fully automatic continuous drying control (ready for plug-in). Energy input oil only 1,1 l per ton heavy grain per 1% humidity extraction. Energy input natural gas only 1,5 m³ per ton heavy grain oer 1% humidity extraction. Rectangular drying tower made of special aluminium (almg 3 hh)). With separate trailor.

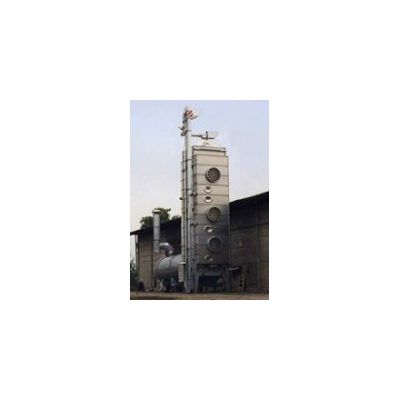

Stationary Dryer

Stationary Continuous and Re-circulating dryers galvanized or made of aluminium Hours output up to 120 t/h in grain with a humidity extraction of 4% or up to 18 t/h in maize with a humidity extraction of 20%.

Feed and Turn Dryer

Apart from drying grain, maize, rape seed and sunflowers, the feed and turn dryer in particular was developed for easy drying of wooden pellets, peat pellets, wooden shred, plastic flakes, foliate plants, grass, granules or similar products.

Milling and Mixing

Riela - Grain Mills

High quality demands on our food require that good grain and components be used for unloaded feed. The own grinding and mixing plant with an individual recipe ensures good and unloaded compound feed. An adapted for the operation feed mixing plant requires a needs-based storage of grain and components. RIELA designs compound feed systems for every farm. Whoever implements this produces food that the end user wishes. RIELA grain mills with and without throw blowers are designed for grinding cereals, corn and legumes. RIELA flour mills can be equipped with different sieves to achieve the optimal and individual structure for each feed. The grain mills are supplied in steel and are suitable for permanent use.

Hall Construction

Riela - Grain Warehouses

RIELA cereal halls offer many options for protecting grain, maize, rice, oil crops, legumes and pourable bulk materials from environmental influences. Galvanized steel trapezoidal walls, galvanized square cells or modular walls are the solutions to make the walls of grain halls sprayable. Automated systems for filling and ventilating the grain halls are available individually.

Riela - Industrial Halls

RIELA Industrial Halls: No other storage room offers so many opportunities to protect all kinds of goods from environmental influences. The installation of shelving systems creates a high storage capacity. The special profiles used in the RIELA hall construction from our own production are bolted constructions, and can be installed according to instructions in own contribution. The outer walls can be supplied with trapezoidal sheets, panels or in insulated panels in a RAL color. Our modular system can be loaded into containers for overseas transports. This saves freight volume and freight costs.