- Livestock Spreader

- Spreader Mounting Options

- Horizontal Rotary Feed Mixer- Truck

- Horizontal Rotary Feed Mixer- Trailer

- Vertical Feed Mixers - Truck

- Vertical Feed Mixers - Trailers

- Truck Compost Mixers

- Trailer Compost Mixers

- Feed Delivery Boxes - Truck

- Semi Trailer Feed Delivery Boxes

- Manure Spreaders - Trucks

Roto-Mix products

FSI - Model Fp2 - Commercial Compost Spinners

The FSI `Fp2 Commercial Compost Spinner` is a unit that stands out from in a crowd. This unit has the ability to broadcast composted material 60 feet wide and up to 8 ton, with even & unmatched uniformity in One Pass Application. The `Fp2 Commercial Compost Spinner`is outfitted with Scales & Digi-Star display combined with the Trimble Ez-Guide 500 & Ez-Steer system to accurately apply your desired rates.

Delivery System

FSI has built forage boxes for over thirty years, it isn`t uncommon to see 20 year old units still feeding cows. FSI, has utilized 30 years of experience combined with new components and design to produce a new series. Today not only is equipment bigger and used more frequently, down time must be kept to a minimum. The performance & reliability of a fully hydraulic driven Commercial Delivery Series meets those demands. They still feed baled hay, corn silage just like the old units, if needed.

Livestock Spreader

FSI - Spreader Cab Control Panel

Two gauges display the pressure on both the floor and beaters. Being able to see the pressures allows you to better operate your spreader.An hour meter to the right of the pressure gauges shows how many hours the hydraulic system has been running.The variable speed floor control below the pressure gauges, allows the adjustment of the floor speed up to an unloading time of less than 90 seconds when you are using the spreader to stock pile or when you are unloading silage. The switch in this control is used to stop the floor. An example of its use would be, when turning around at the end of a field there is no need to disengage the PTO, just flip the switch.The PTO controller is also located in this panel for convenience of operation.Two switches below the PTO controller open the slurry gate and swing out the beaters.Control the spreader from the Cab.

EzSpred - Fp with Hi-Sides

The optional Hi- sides increase the capacity of the EzSpred. J bolts are used to fasten the 3 & 4 foot sides through the stake pockets, which are standard on the spreader. The inside height of the spreader becomes 74` on the low side and 86` on the high side. The swing out tail gate is latched in the floor chains. From the cab console start the floor and the tailgate unlatches. The slanted tailgate, helps with more uniform unloading and quicker clean out. After unloading, start rolling forward and hit the breaks once and the tailgate latches back in the floor. Unloading time is less the 90 seconds and can be as low as 78 seconds. Twelve ton loads are common.

Spreader Mounting Options

FSI - Traditional 10 Wheeler Truck Mount

Traditional 10 wheeler truck mounts. Versatile and built to endure all types of use.

FSI - Model HWY - Farm Trailer

Designed for both in the field and over the road use.

FSI - Model 2870 - Farm Trailer

For dedicated in-field use. Chains: 3 x 88C. Body WxH: 90" x 44". Lengths: 24`-30`.

Horizontal Rotary Feed Mixer- Truck

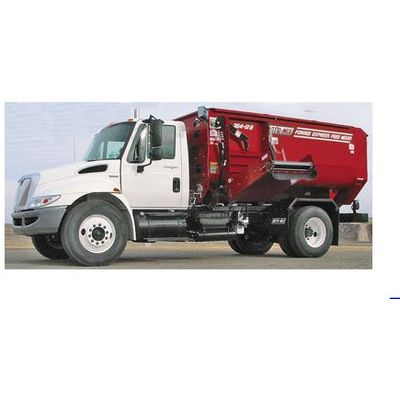

Roto - Model 274-12B - Commercial Horizontal Feed Mixer

The 274-12B Commercial is a horizontal rotary feed mixer with a mixing capacity of 270 cu. ft. and can hold a maximum load with a heavy ration up to 8100 lbs. It comes standard with the patented Roto-Mix® Mixing System. The optional Staggered Rotor and the Hay Shear Bar is available. This size of mixer works well with small to medium-sized dairy, cow/calf, and feeder operations.

Roto - Model 354-12B - Commercial Horizontal Feed Mixer

Designed with commercial cattle feeders in mind, this rugged unit uses two 30" diameter low speed augers in the bottom, bringing the feed forward without a boiling action to two cross augers. The cross augers then move the feed to the discharge conveyor for fast, efficient and even feed delivery. With ROTO-MIX, there are no high wear, high maintenance and high cost floor chains.

Horizontal Rotary Feed Mixer- Trailer

Roto - Model 274-12B - Commercial Series Feed Mixer Trailer

Trailer models are mounted on heavy-duty tubular steel trailer frames, complete with built-in scale mountings. Heavy-duty eight- or ten-bolt hubs and spindles with a selection of tires for eight- and ten-hole wheels. The single pole trailer tongue is constructed of heavy wall tubing for a shorter turning radius. A sturdy rear bumper and an adjustable, replaceable trailer hitch clevis are also standard equipment.