- Home

- Companies

- S3 AWS Airbar

- Products

S3 AWS Airbar products

S3 AWS Airbar - Floor Kits for Enhanced Feeding Systems

The S3 AWS Airbar® Floor Kit is designed to replace the factory stone dam or floor with a streamlined, low-profile stainless steel panel, thereby improving the feeding process. The refined profile of these Floor Kits significantly enhances the functionality of the established Airbar® systems. Available for select models of John Deere, Case IH, and New Holland, these kits deliver key benefits including improved feeding efficiency, prevention of crop bunching, and full-width head coverage. Constructed from durable stainless steel, these kits are robust and efficient, ensuring reliable performance in demanding agricultural applications. Head models supported include JOHN DEERE: 900F, 600F, and 1020 series, Case IH: 2020 and 3020 series, and New Holland: 73C, 74C, and 740CF series, with multiple head lengths ranging from 20 to 35 feet.S3 AWS Airbar - Draper Brush Kits for Consistent Canvas Tension

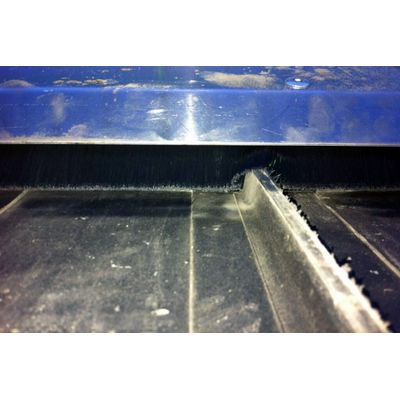

The S3 AWS Airbar Draper Brush Kit is engineered to maintain consistent canvas tension during the harvesting process. This kit prevents debris from entering the rear of the canvas and accumulating on the drive rollers, which can lead to operational inefficiencies and increased maintenance. The system features a stainless steel deflector combined with a fine bristle brush to create an effective seal, reducing both crop loss and header maintenance. Designed to be compatible with all popular draper models, this kit runs the full width of the header for comprehensive coverage. Key benefits include preventing clogging under the canvas, improving yields, and offering a robust solution to maintain equipment performance during harvest.

S3 AWS Airbar - Flow Dynamics System

The S3 Airbar Flow Dynamics (FD) system introduces a revolutionary airflow mechanism designed for modern agricultural needs. This advanced system leverages a closed-circuit, twin-channel airflow design that independently pressurizes the air manifold from both ends. This configuration culminates in a consistent high-pressure airflow delivered precisely to the last nozzle on each channel, optimizing the efficiency of pressure-hungry headers over 45 feet. This innovative system promises up to a 25% enhancement in evenly-distributed nozzle pressure without requiring additional input power. The unit is compatible with both draper and auger headers and features articulating end caps at the circuit's ends to ensure no loss in efficiency due to air turbulence. By incorporating the AWS Airbar, farmers can expect reduced shatter loss during soybean and pulse crop harvesting, as the high-velocity air stream ensures materials are directed into the feeder-house, minimizing pod shelling and loss. This results in increased yields, improved feeding efficiency, faster ground speeds, and reduced wear and downtime for cutting equipment.S3 AWS Airbar - Advanced Air-Assist Harvesting System for Combines

The AWS Airbar is an advanced air-assist harvesting system designed for high efficiency and performance. It features a purpose-built S3 AWS blower assembly and utilizes a single-channel, wraparound, closed-circuit air system. Centrally located on the combine header, powered by the feeder house reverser gear, the airflow system effectively covers both the back and front of the header. This technology is compatible with both draper and auger headers and is particularly beneficial in harvesting soy and pulse crops by reducing shatter loss and debris accumulation at the cutting head. Key benefits include improved feeding efficiency, reduced equipment wear, and increased yields by as much as 4 bushels per acre. The high-velocity airstream keeps the cutting head clear, enhances ground speed, and ensures an even flow of material through the feeder house, ultimately improving overall operating efficiency. The AWS Airbar system is designed for various header models from leading brands such as AGCO, Case IH, Claas, and more.

S3 AWS Airbar - High-Efficiency Air-Assist Harvesting System

The AWS Airbar FDX incorporates a high-efficiency, dual-channel airflow system similar to that of the Airbar FD, but enhances it with a high-output X-model fan and chassis system. This results in up to 50% more air pressure compared to the standard Airbar. It is designed for high-demand operations and is compatible with both draper and auger headers. The additional air pressure helps to maintain a highly efficient power output, which is essential for large combine header sizes. This model's advanced drive assembly and fan offer substantial improvements in harvesting soy and pulse crops, reducing shatter loss at the cutting knife and minimizing debris clutter, hence, maintaining high cutting efficiency. Implementing the AWS Airbar® system on a combine header enhances material flow and feeding efficiency, increasing yields by up to 4 bushels per acre. Overall, it promotes faster ground speeds, better operational efficiency, and reduces equipment wear and downtime by providing consistent and high-velocity airflow.