SDF Group products

Precision Farming

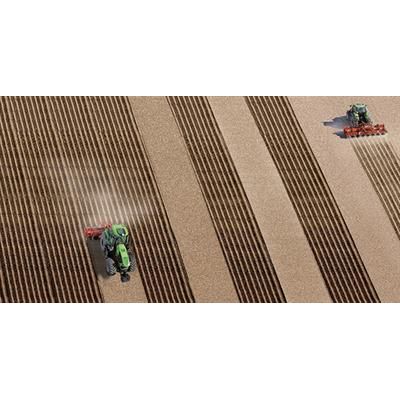

SDF - Intelligent Systems for Leading-Edge Agriculture

Precision Farming technologies are developed for professionals and are designed to considerably improve efficiency thanks to the optimum management of individual work areas and synchronisation of all operations - all while safeguarding resources and production processes.

Agrosky - Precision Farming Satellite Systems

All satellite systems. Three levels of precision. A single receiver. Designed for satellite monitoring of tractors and equipment, Agrosky is an advanced Precision Farming system which, via a connection with satellite receivers, allows the vehicle to be driven with accuracy, optimising productivity and cost of ownership.

SDF - Tractor Implement Management System (TIM)

Maximum precision: the equipment takes command. Maximum efficiency is achieved when the tractor and equipment work together as a single unit. The TIM (Tractor Implement Management) system accomplishes this by creating a self-propelled working machine. TIM can be implemented across a number of products in combination with specific equipment, such as the Krone baler, improving efficiency and comfort of the operator and limiting driving to within optimum performance ranges.

Other Products

MaxiVision - Cab

Winner of the German Design Award 2014, the MaxiVision cab is a modern, high-tech workplace which sets new standards in terms of ergonomics and functionality: a dynamically suspended driver`s seat, a comfortably upholstered passenger seat and an innovative climate control system.

SDF - Model CVT - Transmission

SDF considers management of the entire transmission design and implementation process as strategic, along with other core elements of the tractor - the engine, cab and axle. This is why it invests considerable sums every year in Research and Development.

iMonitor - Central Control Unit

A solution for every application. iMonitor is the central control unit which enables the management of all Precision Farming applications. The perfectly-structured single user interface is easy to use, and can even provide operators with remote access assistance.

SDF - Automatic PTO Speed Change Gear Unit

A pto gear unit that can be switched under-load has been realized for the first time. Depending on the engine load, switching takes place automatically between nominal pto shaft speed and eco shaft speed. This is of particular benefit where conditions of use change frequently and it expands the spectrum of the eco pto shaft applications considerably – instabilities in operation are avoided.

SDF - Automatic Trailer Hitch Coupling

Equipment with camera-based environmental recognition system for controlling tractor movements. The cameras identify the position of the hook of a certain tool with respect to the tractor and the control system determines the best path for the coupling and performs all the necessary movements automatically. The proposed solution improves operation, operator comfort and safety conditions.