- Grain Handling Equipment - Grain Intake

- Grain Equipment - Grain Cleaners

- Feed Mill Unit

- Breeding Equipment

- Feed Milling - Fed Production Equipment- Intake

- Feed Milling - Fed Production Equipment- Drying

- Feed Milling - Fed Production Equipment- Cleaning

- Feed Milling - Fed Production Equipment- Storage Systems

- Farm Systems- Dry Feeding

- Farm Systems- Liquid Feeding

Skiold A/S products

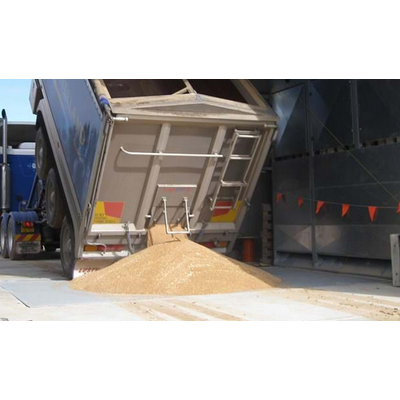

Grain Handling Equipment - Grain Intake

Skiold - Grain Intake System

A grain intake system is part of a SKIOLD grain storage solution or a SKIOLD feed milling plant. SKIOLD has a complete range of full-line equipment for the grain and other raw material intake whether it is from bulk or bags.

Grain Equipment - Grain Cleaners

Skiold - Grain Cleaner

The raw material (1) is conveyed to the screen drums (3) via the distributor (2). The drums rotate in a planetary movement, i.e. around their own axis (4) while the drum axes rotate around the centre of the machine at the same time. The centrifugal force flings the grains towards the screen walls (5) and separation is achieved when the smaller grains pass through the screens. Large and coarse particles are removed on the inner screens. The grain is collected in channels (6) at the periphery of the machine and discharged from the outlets (7). The clean material leaves the machine through the outlet (10) of the aspirator (8). Light particles (9) are drawn by a fan to a cyclone or similar dust collector.

Feed Mill Unit

Airflow mix - Model MH1500 - Feed Mill Unit

Fresh boost ! Behind this new feed mill, these are 15 years of experience acquired in feed production and in pneumatic conveying associated to current techniques that have served as a basis to design this new range of on-farm feed mill units in an industrial logic. Blender capacity of 1500 kg with a tank in water-drop shape closely to the auger ensuring an inside self washing. Decrease of maintenance operation thanks to the planetary gear motor at shaft end. Optimised pneumatic with a specific cylinder equipped at its base of a tight sealed valve with complete opening. A buffer hopper assures the grinding continuity without disruption. A clean feed mill unit thanks to a self- cleaning cyclofilter. This new generation of feed mill unit meets needs from 2000 to 8000 tonnes per year (throughput rate from 1.5 to 8 tonnes / hour).

Model RS 350 - Crusher

Ideal flattener for any size of grain (cereals, corn, peas, lupin, horse, bean,..)alone or mixed. The big grains are first crushed between the little roller and one of the largest rollers ; flattening is then made between the two large rollers. Specialist in breeding equipment for over 60 years SKIOLD- ACEMO has emerged over time as one of the best specialist in the food preparation equipment. Ecomonic constraints related to the advancement of knowledge in animal nutrition make use of the flattened cereals increasingly widespread in our farms. Based on the experience with thousands of flatteners, SKIOLDACEMO has developed the RS 350 to expand its range and to offer to farmers the most suitable product to their needs.

Model RS 380 - Crusher

Extremely quiet. Ideal for grains of all sizes alone or in blend. Throughput : 4 kW from 600 to 1100 kg/h. 5,5 kW from 750 to 1400 kg/h. 7,5 kW from 850 to 1750 kg/h.

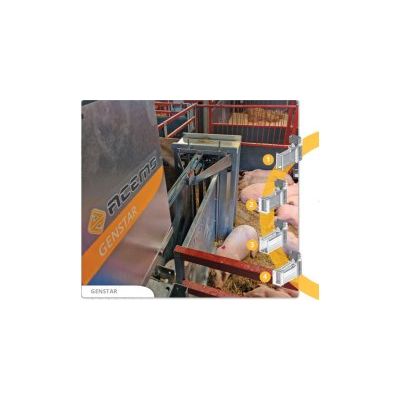

Breeding Equipment

Genstar - Boar Testing Station

TEST the Feed consumption & The daily gain With the BEST PRECISION ON THE MARKET

Feed Milling - Fed Production Equipment- Intake

Cleaners

SKIOLD`s cleaners are suitable for cleaning of all common cereals, maize, and peas used for livestock feed. SKIOLD`s range includes two types of cleaners; a screen cleaner and a drum cleaner. The capacity ranges from 500 kg/hour to 5 tons/hour, if the cleaner is placed in the feed mill. If the cleaner is placed directly after the intake hopper, the capacity is somewhat higher, from 30 to 200 tons/hour. Placed after the intake, they function as pre-cleaners in connection with storing and/or drying. Both cleaners are prepared for mounting of dust aspiration. Most often, a magnet is placed before the cleaner to separate magnetic metallic impurities.

Feed Milling - Fed Production Equipment- Drying

Moist Grain Silos

One or more silos for moist grain, called wet bins or buffer silos, are often part of the drying plant. These work as pre-bins for the dryer, and ease separation of moist and dry grain, by which they contribute to an optimum utilization of the drying plant. The silo works as pure buffer/storage bin, and has a typical capacity of 40-100 tons.

Grain Drying Plants

Generally speaking, there are two principles for drying; continuous flow drying and on-floor drying. The continuous flow dryer is characterized by a high degree of flexibility when drying different raw materials. It is also suitable for very moist products. The continuous flow dryer is often used in grain storage plants with large outdoor flat-bottom steel silos. The on-floor drying plant combines the storage and drying function. It is suitable for drying of grain and seeds, but not for very moist products.

Feed Milling - Fed Production Equipment- Cleaning

Twin Drum Cleaner

The SKIOLD twin drum cleaner is designed for efficient cleaning separating both under- and oversized impurities from many different sorts of raw materials for animal feed e.g. wheat, barley, maize, peas, etc.