Smart Enviro Systems Pvt. Ltd products

Smart xpress - Composter

Mechanical composting is the most effective method of urban waste disposal.The construction comprises an inbuilt shredder and a cylindrical container. The churning system crushes and mixes the waste matter simultaneously to break it down, shrinking the volume and making pre-decomposition quicker. The heating element of the Organic Waste Composter provides the extra heat to optimize the action of the microorganisms and accelerate the composting process to yield ready-to-use compost.

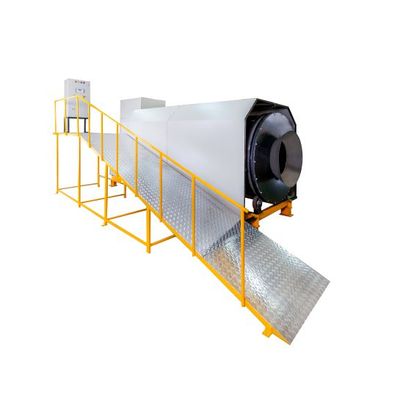

Smart - Drum Composter

The machine is developed on the principle of providing a complete composting system in a single machine. The input is first fed to the shredding mechanism which reduces the size of the waste material and maximizes the surface area to micro-organisms for quick composting. Aerobic composting being an exothermic process generates heat which further helps in removing the moisture by evaporation and renders dry, ready-to-use compost in a few days. The compost can be unloaded at uniform levels from the discharge end. The air exchanges from the composting chamber ensure adequate availability of air required for aerobic composting.

Smart - Batch Composter

The machine consists of a shredder and mixer for simultaneously mixing and shredding of waste to uniform size. The machine also mixes the composting culture and dry material such as dry leaves, sawdust etc. with the shredded waste for absorption of excess moisture.

Smart - Covered Aerated Static Pile Composter

Aerated static pile composting is an improved version of windrow composting. Here too, the waste is arranged in piles or rows. But an air pipe is provided underneath to augment oxygen supply and thereby prevent formation of anaerobic conditions. Typically, air is drawn through the pile with the help of a blower. The blower capacity is determined according to the established oxygen demand characteristics of the rotting waste. The air flow rates can be adjusted according to the stage of rotting and the temperature attained in the core of the waste. To this effect, appropriate probes can be inserted in the piles which are then coupled with a microprocessor for blower operation.