Steiner Automation GmbH & Co KG products

Fodder Mixing Systems

Steiner - Dynamic Fodder Mixing Plant with Wet Corn Feeding

Dynamic fodder mixing plants with wet corn feeding offer an efficient approach to mixing and distributing poultry feed. Unlike traditional systems with a single weighing hopper, these plants are capable of producing much larger quantities of fodder. Utilizing smart algorithms, the system can seamlessly transfer the right fodder recipe to each barn or compartment according to specific requirements. The system’s design allows for flexible control of mills and agitators, providing the option to add oil when necessary. This adaptability not only saves on costs and energy consumption but also addresses and mitigates potential technical challenges that were common in older systems, marking a significant advancement in poultry feeding technology.

Mobile Barns for Laying Hens

Steiner PICCO - Mobile Barn for Laying Hens

The PICCO mobile barn represents an innovative solution in poultry farming, specifically designed for laying hens. With a compact width of 3 meters, this roadworthy barn can be effortlessly transported between locations without requiring a permit. It accommodates up to 400 free-range or 350 organically-farmed laying hens. Key features include a 1-ton integrated fodder silo, an electric egg conveyor, and an electric manure removal system. The barn offers fully insulated walls, roof, and underfloor, alongside advanced climate, feeding, and lighting control systems managed via an intelligent TOUCH housing computer. Options for customization include a self-sufficient water and energy supply system, SMS alerts, remote access, and a robust cold scratching area. This adaptable setup ensures optimal environmental conditions and ease of maintenance, making it a compelling choice for modern poultry farming.

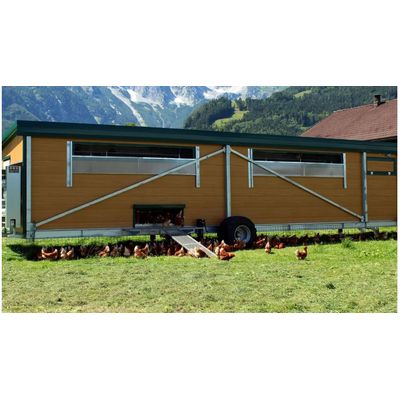

Steiner - Model COMPACT - Mobile Barn for Laying Hens

The COMPACT mobile barn is a fully-equipped and operational housing solution for poultry, designed for ease of use and efficiency. It caters to free-range and organic farming needs, accommodating up to 666 free-range hens or 540 organic laying hens. Key features include a 2 x 3 m entrance area for equipment and storage, an electric egg conveyor for egg collection, and electric manure conveyors for simplified waste management. The barn has an integrated fodder silo with a capacity of up to 2.5 tons, and a pneumatic filling system for the fodder bag. An intelligent TOUCH housing computer manages fully automatic feeding, climate control, and other essential operations. The structure boasts fully insulated outer walls and roof, ensuring energy efficiency. Optional features include tyres for grassland, photovoltaic systems for a self-sufficient setup, and remote access capabilities, providing versatility and adaptability to various farming environments.

Stationary Barn Technology for Poultry

Steiner - Model PRO-Fix - Modular Barn for Laying Hens

The PRO-Fix modular barn system is designed to provide a flexible poultry housing solution starting from a capacity of 1600 laying hens, expandable through a modular construction approach. The basic barn measures 19.20 meters in length and can be extended in 5-meter increments to accommodate varying farm sizes. Central to its design is optimized installation speed, superior quality, and cost-effective operation. The barn features include a well-insulated structure, automated climate, feeding control systems, intelligent barn computer, and efficient manure removal. Moreover, it incorporates the advanced SiMPLEX aviary system and automated egg handling processes ensuring efficient production. Adaptable for different foundations and offering potential for resale, this solution prioritizes efficiency and adaptability to meet future poultry farming needs.

Steiner SiMPLEX - Aviary System for Poultry

The SiMPLEX aviary system is engineered to enhance poultry management by offering a highly efficient setup for laying hens and breeding stock. A central feature is its centrally located egg collection belt which simplifies the process of collecting clean eggs, eliminating the need for manual system egg collection. Its construction is designed to allow easy access for maintenance, ensuring satisfaction at both the farmer and livestock levels. The system supports automated operation through the TOUCH barn computer, which facilitates remote management and alerts via SMS or phone, ensuring operational integrity. Technical specifications include a system width of up to 3000 mm for stationary barns and 1500 mm for mobile variants, with a clear and organized layout to improve food and water availability directly in front of the nests. This optimizes the conditions for egg production and animal well-being while providing convenient monitoring through its low height, enhancing day-to-day barn operations.